A kind of group tower crane with jib

A tower crane and crane technology, applied in cranes and other directions, can solve the problems of inability to meet the long cross arm of UHV lines, the need for heavy tower assembly, the large cross-sectional size and weight of the tower body, and the lack of installation of a balance arm. The effect of convenient collaborative operation, less space occupation, and flexible speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the special-purpose tower crane for erecting iron tower construction with auxiliary arm of the present invention is described in further detail.

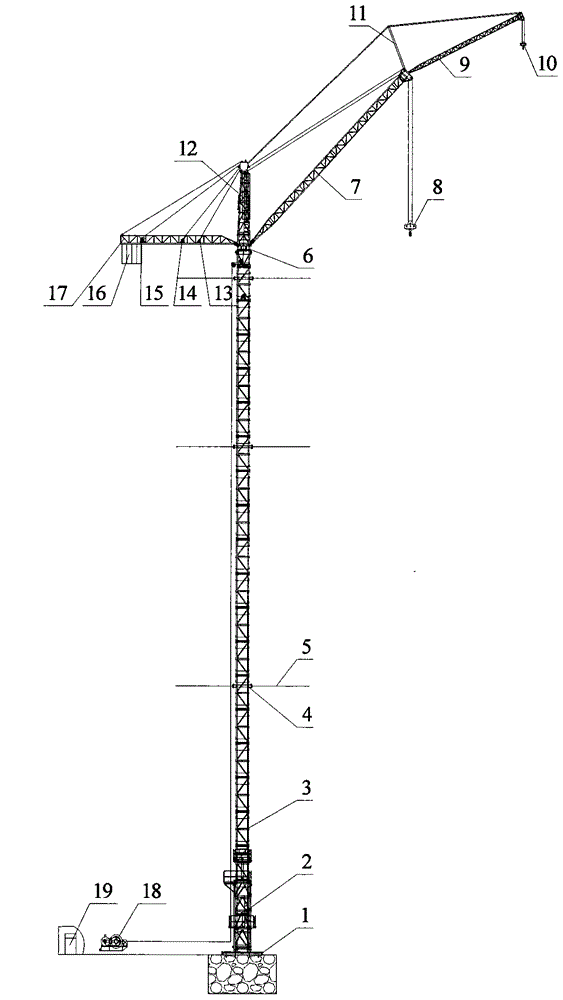

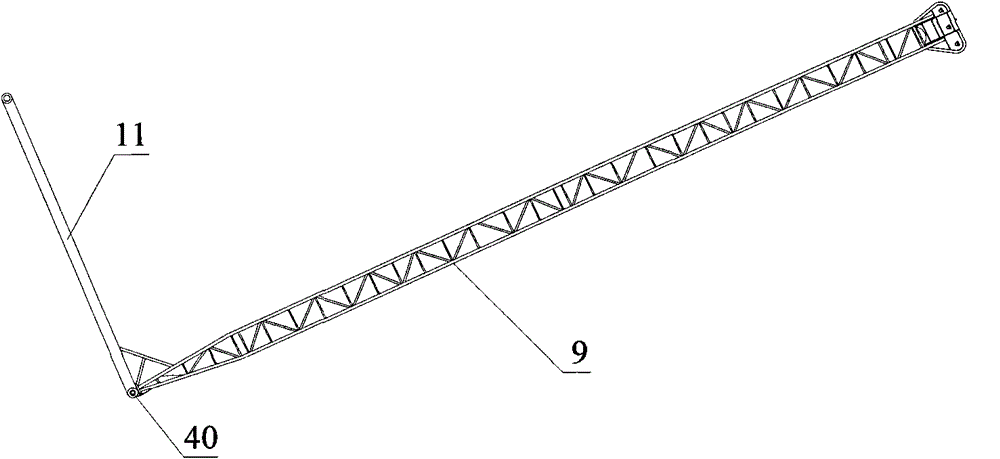

[0032] Such as figure 1 As shown, a special-purpose tower crane with a jib for erecting transmission line iron towers according to an embodiment of the present invention mainly includes: a steel structure base 1, a jacking frame 2, a tower body 3, an attachment frame 4, Attached wire rope 5, slewing support device 6, main arm 7, main hook 8, auxiliary arm 9, auxiliary hook 10, strut 11, tower head 12, auxiliary arm luffing mechanism 13, main arm luffing mechanism 14, auxiliary lifting Mechanism 15, counterweight 16, balance arm 17, main lifting mechanism 18 and control room 19.

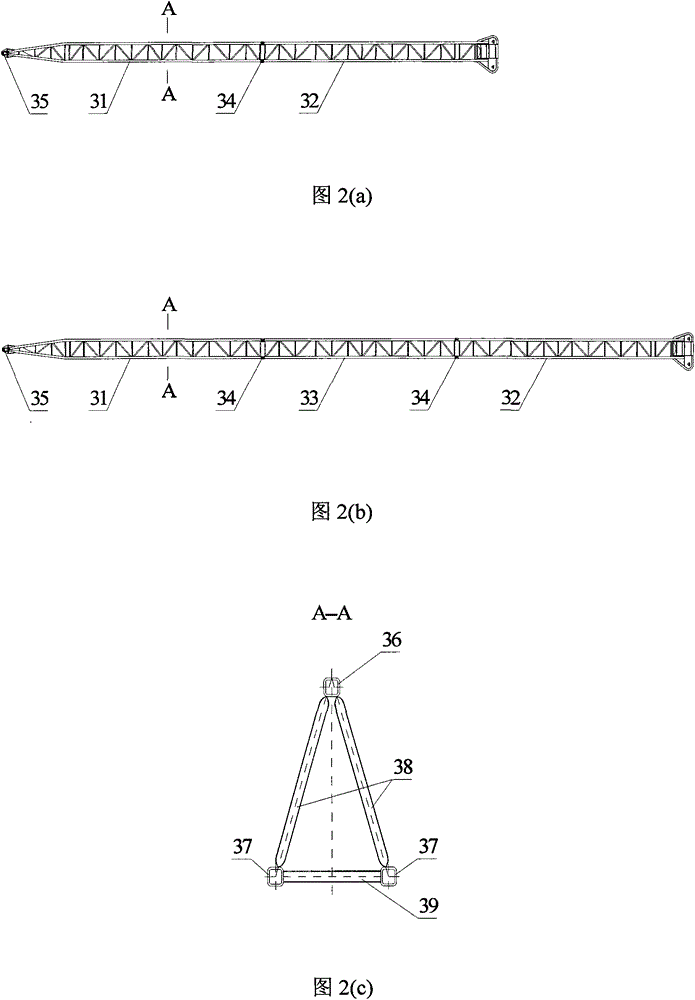

[0033] The main boom 7 is a space truss structure, which is assembled by connecting 2 to 3 boom sections through pin shafts. figure 2 Shown is a schematic diagram of the main arm 7, wherein figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com