Construction method for road edge stone sliding mode

A construction method and technology for kerbs, applied in the direction of side ditch/curb, climate change adaptation, etc., can solve the problems of long construction time, poor road flatness, inconvenient kerbs, etc., to reduce maintenance costs, Consistent color, simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

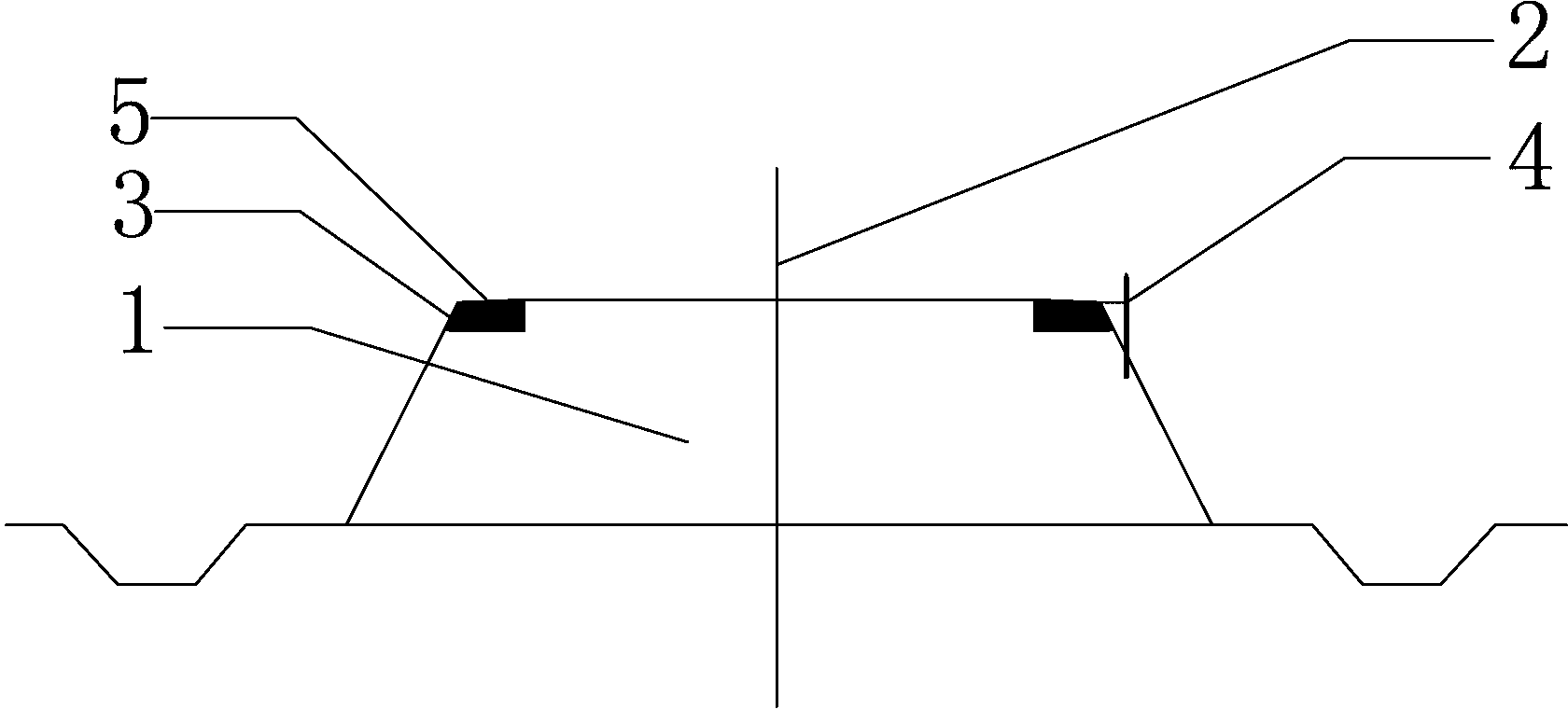

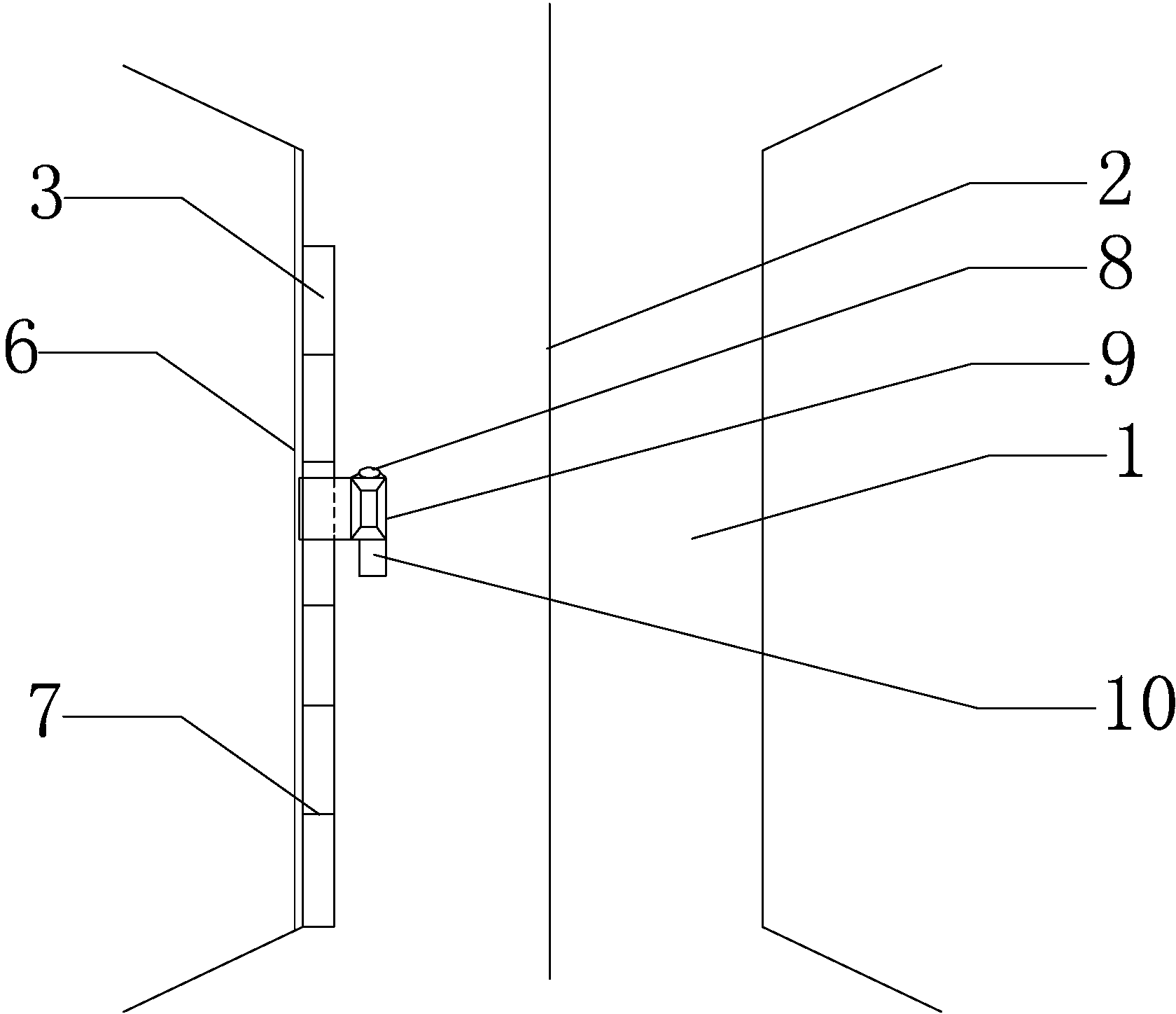

[0042] Roadside stone sliding form construction method of the present invention is characterized in that comprising the following steps:

[0043] a. Provision of roadside stone base

[0044] The base of the roadside stone is the soil road shoulder. The size and depth of the roadside stone paving trench shall be guaranteed according to the drawings, and the side and bottom surfaces shall be leveled and compacted. The degree of compaction shall be greater than the design requirements, and the deviation of the flatness shall be less than 20mm.

[0045] b. Stake out along the stone edge

[0046] The straight line section of the roadside stone is staked out according to the road center line after the review. After stakeout, a steel bar is erected every 25m on the side slope of the roadbed, and the steel wire guideline is fixed on the steel bar. Pull the steel wire guideline for positioning, and use a level Measure the elevation of the guideline; carry out encrypted measurement and...

Embodiment 2

[0062] In addition to step a, the roadside stone base is the pavement base. Groove according to the size of the drawing, and check whether the compactness of the roadside stone base meets the design requirements and the roadside slipform machine is manufactured by Jiacheng Machinery Factory, Lulong County, Qinhuangdao City Except the GZD type full-automatic curb sliding form machine, all the other are with embodiment 1. The use of a fully automatic curb slipform machine makes the construction process smoother and the quality of curb paving is higher.

[0063] The curb stone sliding form construction method of the present invention is also applicable to the construction of road shoulder stones and curb stones.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com