Drilling machine with automatic drill stem disassembling device

A technology for automatic disassembly and assembly of drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inconvenient transportation and space occupied by the device, and achieve the effect of convenient transportation, small space occupation and guarantee of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

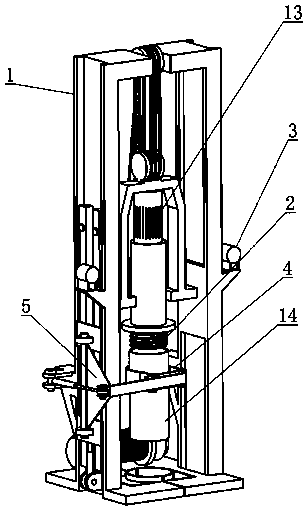

[0030] The utility model relates to a drilling rig with an automatic dismounting device for drill rods, which includes a working vehicle and a frame system. like Figure 1-2 As shown, the frame system includes a frame 1, a main drill pipe 2, an elevator 3 and a manipulator.

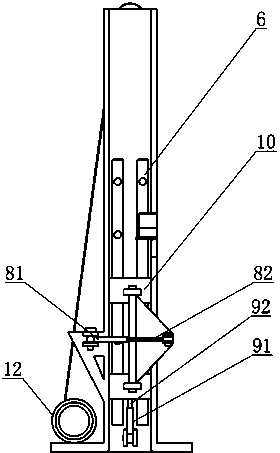

[0031] A slide mechanism is provided on the side wall of the frame 1, and the slide mechanism includes a slide rail 6, a slide block 10 and a third pushing mechanism. The slide rails 6 are fixed on the side wall of the frame 1, and there are two slide rails arranged vertically and at intervals in the horizontal direction. There are two sliders 10 spaced up and down, and the two sliders 10 are respectively stuck on the slide rails 6 . The third pushing mechanism is fixed on the side wall of the frame 1, and includes a third hydraulic cylinder 91 and a third hydraulic rod 92 located below the lower slider 10, and the top end of the third hydraulic rod 92 is fixedly connected with the bottom end of the low...

Embodiment 2

[0040] Embodiment 2 A drilling rig with an automatic disassembly and assembly device for drill rods

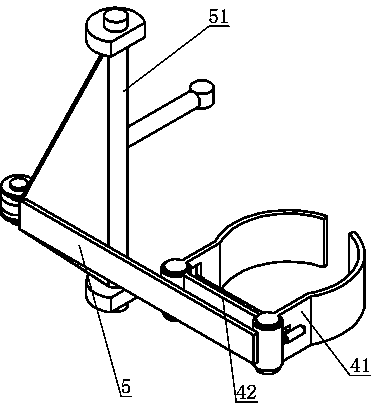

[0041] This embodiment has the same work vehicle and frame system as the structure of Embodiment 1, the only difference is that a plurality of protrusions are distributed on the inner wall of the arc-shaped plate portion of the side wall 41 of the gripper 4, when the gripper 4 and When the drill rod 14 is in contact, the protrusion can increase the contact friction between the arc-shaped plate and the drill rod 14 to prevent the drill rod 14 from slipping. Certainly, the protrusions may also be other structures capable of increasing frictional force, such as a grid-shaped surface, a corrugated surface, and the like.

Embodiment 3

[0042] Embodiment 3 A drilling rig with an automatic drill pipe dismounting device

[0043] This embodiment has the same work vehicle and frame system as that of Embodiment 1, the only difference is that a contact sensor is provided on the inner wall of the arc-shaped plate part of the side wall 41 of the gripper 4, and the contact sensor is used to detect For the positional relationship between the gripper 4 and the drill rod 14, the contact sensor transmits a signal to the control unit when the drill rod 14 contacts the drill rod 14, and the control unit controls the first hydraulic cylinder 71 to stop working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com