Bared oil-gas pipeline minimum pipe wall temperature measuring method and device

A technology for pipe wall temperature and oil and gas pipelines is applied in the measurement and calculation of the minimum pipe wall temperature of oil and natural gas pipelines, the measurement device for the minimum pipe wall temperature of bare oil and gas pipelines, and the measurement of the minimum pipe wall temperature of bare oil and gas pipelines. Problems such as exposed oil and gas pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

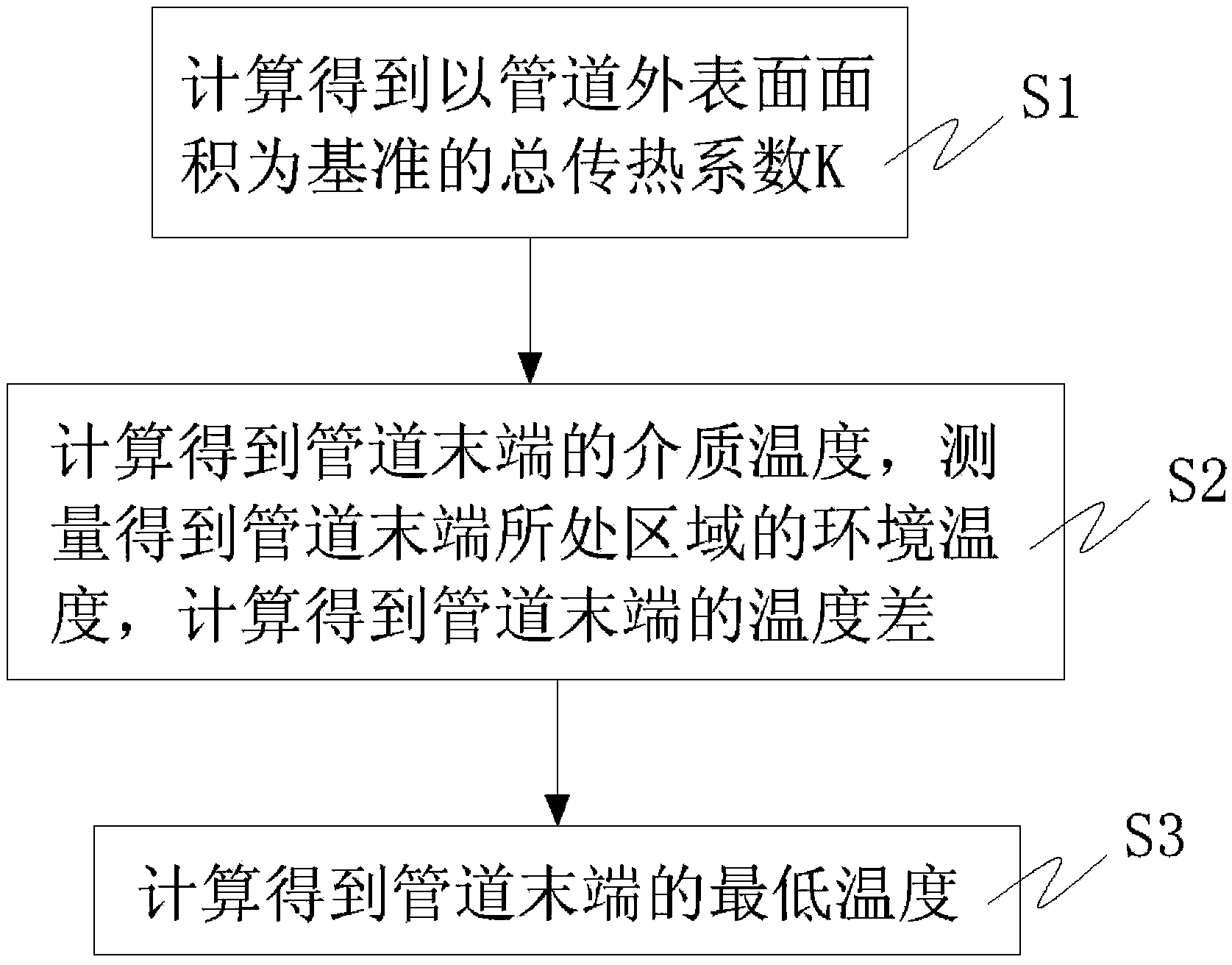

[0048] This embodiment provides a method for measuring the minimum wall temperature of exposed oil and gas pipelines, see figure 1 and figure 2 The measurement method consists of the following three steps:

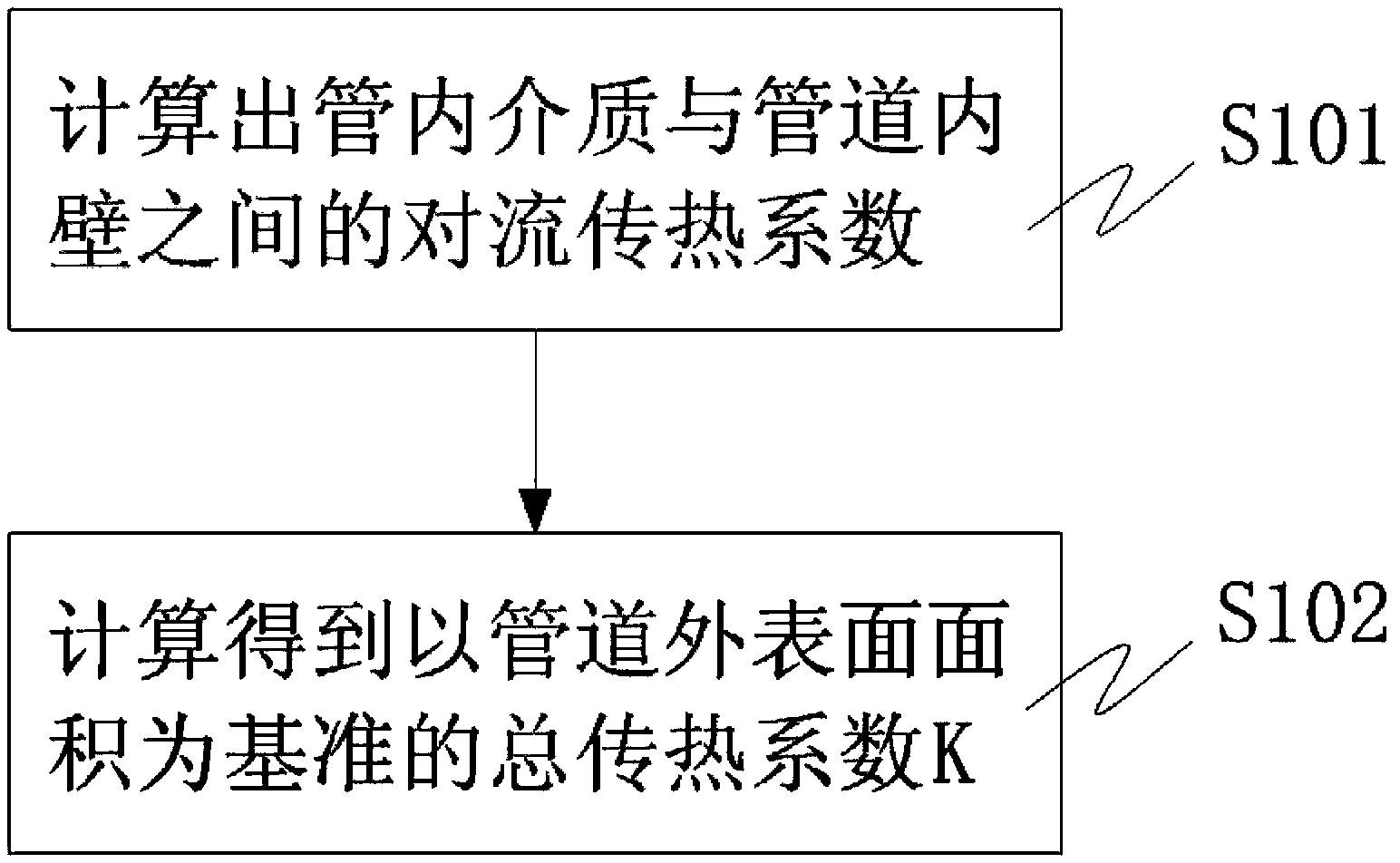

[0049] S1. Calculate the total heat transfer coefficient K based on the outer surface area of the pipeline (unit: W / m2 °C);

[0050] S2. Calculate the medium temperature t at the end of the pipeline 2 (unit: °C), the ambient temperature t of the area where the end of the pipe is located is measured e (unit: ℃), using the medium temperature t at the end of the pipeline 2 Subtract the ambient temperature t in the area where the end of the pipe is located e Get the temperature difference Δt at the end of the pipe (unit: °C): Δt=t 2 -t e ;

[0051] S3. Use formula (1) to calculate the minimum wall temperature t at the end of the pipe min (Unit: °C):

[0052] t min = t e +KΔt / α o (1)

[0053] In formula (1), α o (Unit: W / m2 °C) is the conve...

Embodiment 2

[0069] This embodiment provides a method for measuring the minimum pipe wall temperature of an exposed oil and gas pipeline. The principle of the measurement method in this embodiment and the specific formula used are the same as those provided in Embodiment 1. This measurement method takes a 1000m exposed gas pipeline with a specification of φ610×20mm and operates at an ambient temperature of -40°C as an example, and details the engineering calculation steps of its minimum wall temperature as follows:

[0070] In the first step, query or measure to determine the following basic parameters: the inner diameter of the pipe d i =0.57m, pipe outer diameter d o =0.61m, pipe length x=1000m, steel pipe material heat transfer coefficient λ=16.27W / m °C, gas mass flow rate in the pipe M=6.626kg / s, gas viscosity in the pipe μ f =1.087×10-5kg / m s, constant pressure specific heat capacity C of the gas in the tube pf =2222J / kg °C, heat transfer coefficient of gas in the tube λ f =0.0332W...

Embodiment 3

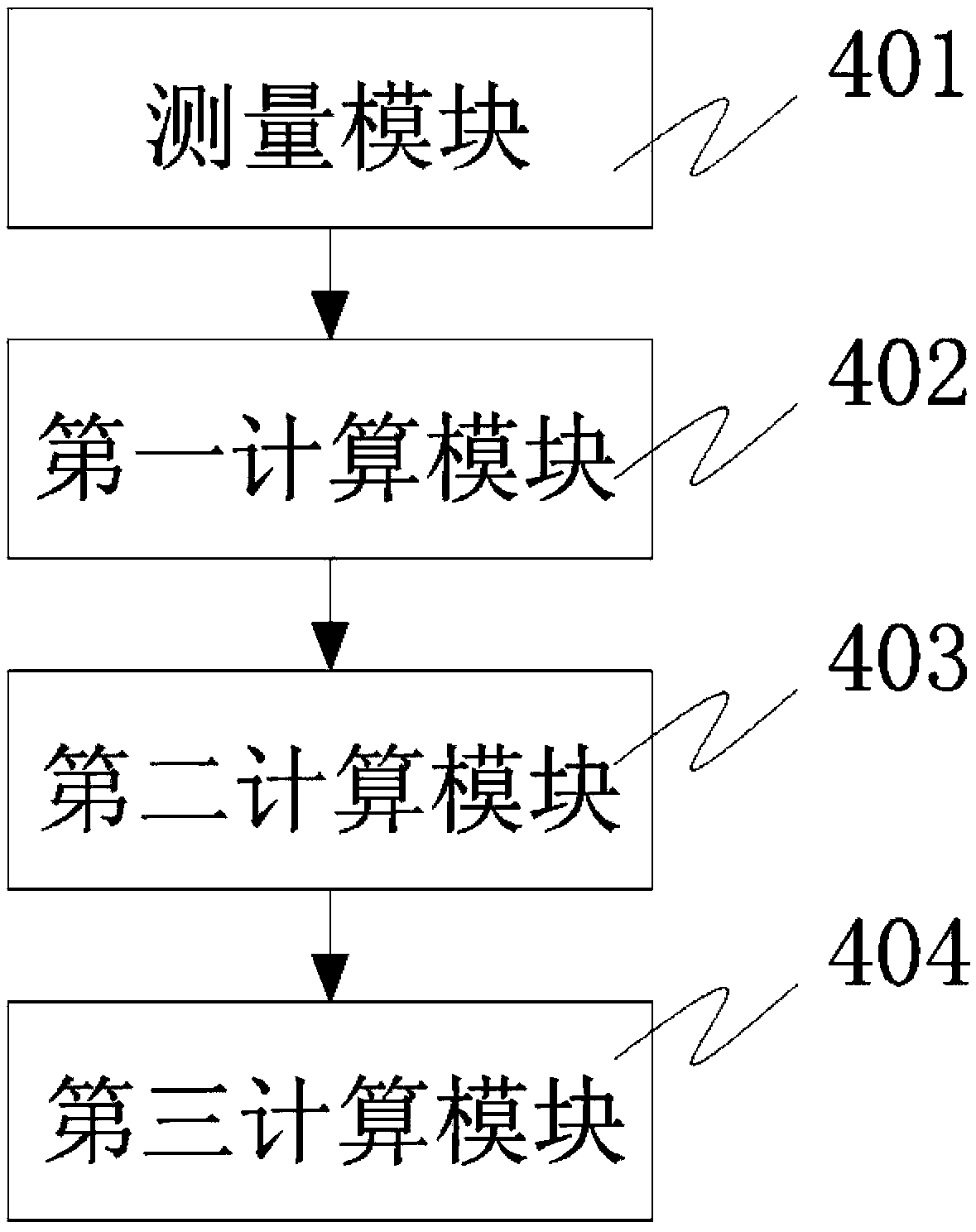

[0089] This embodiment provides a measuring device for the lowest pipe wall temperature of exposed oil and gas pipelines, see image 3 , the device consists of:

[0090] The measurement module 401 is used to measure the ambient temperature t of the area where the end of the pipeline is located e ;

[0091] The first calculation module 402 is used to calculate the total heat transfer coefficient K based on the outer surface area of the pipeline;

[0092] The second calculation module 403 is used to calculate the medium temperature t at the end of the pipeline 2 , according to the measured ambient temperature t of the area where the end of the pipe is located e , using the medium temperature t at the end of the pipeline 2 Subtract the ambient temperature t in the region where the end of the pipe is located e Get the temperature difference Δt at the end of the pipe;

[0093] The third calculation module 404 is used to calculate according to the formula t min = t e +KΔt / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com