CAN-BUS application to ARM-based mining water pump motor control system

A CAN-BUS, water pump motor technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems such as the reduction of the communication rate of the maximum communication distance, improve the ability to deal with emergencies, and reduce accidents The effect of the probability of occurrence of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

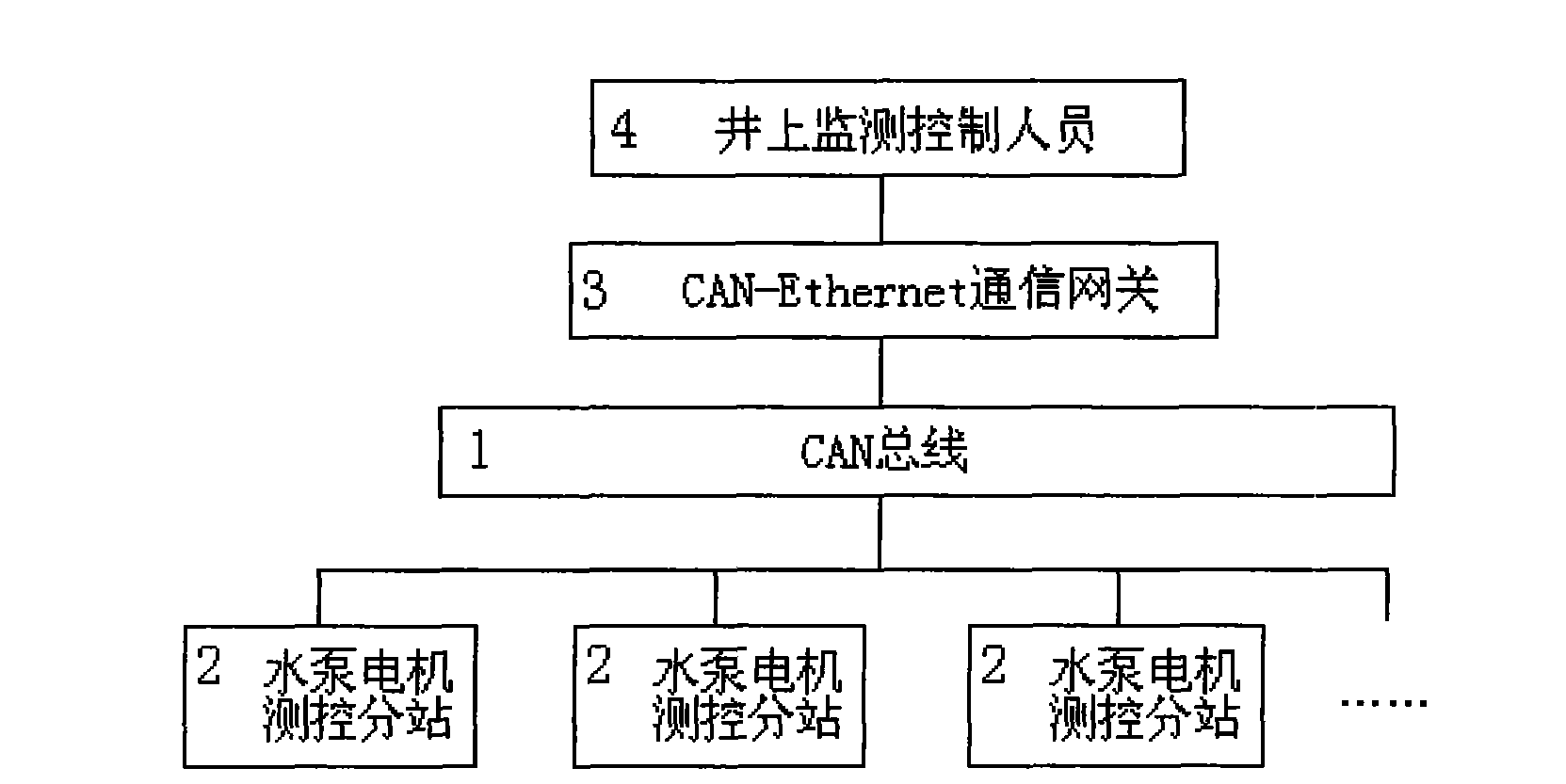

[0018] refer to figure 1 As shown, a kind of CAN-BUS application in the mine water pump motor control system based on ARM includes CAN bus 1 and a plurality of water pump motor measurement and control substations 2, and the data collected by the water pump motor measurement and control substations 2 are sequentially passed through the The CAN bus 1 and the CAN-Ethernet communication gateway 3 are transmitted to the monitoring and control personnel 4 on the well for calculation and analysis.

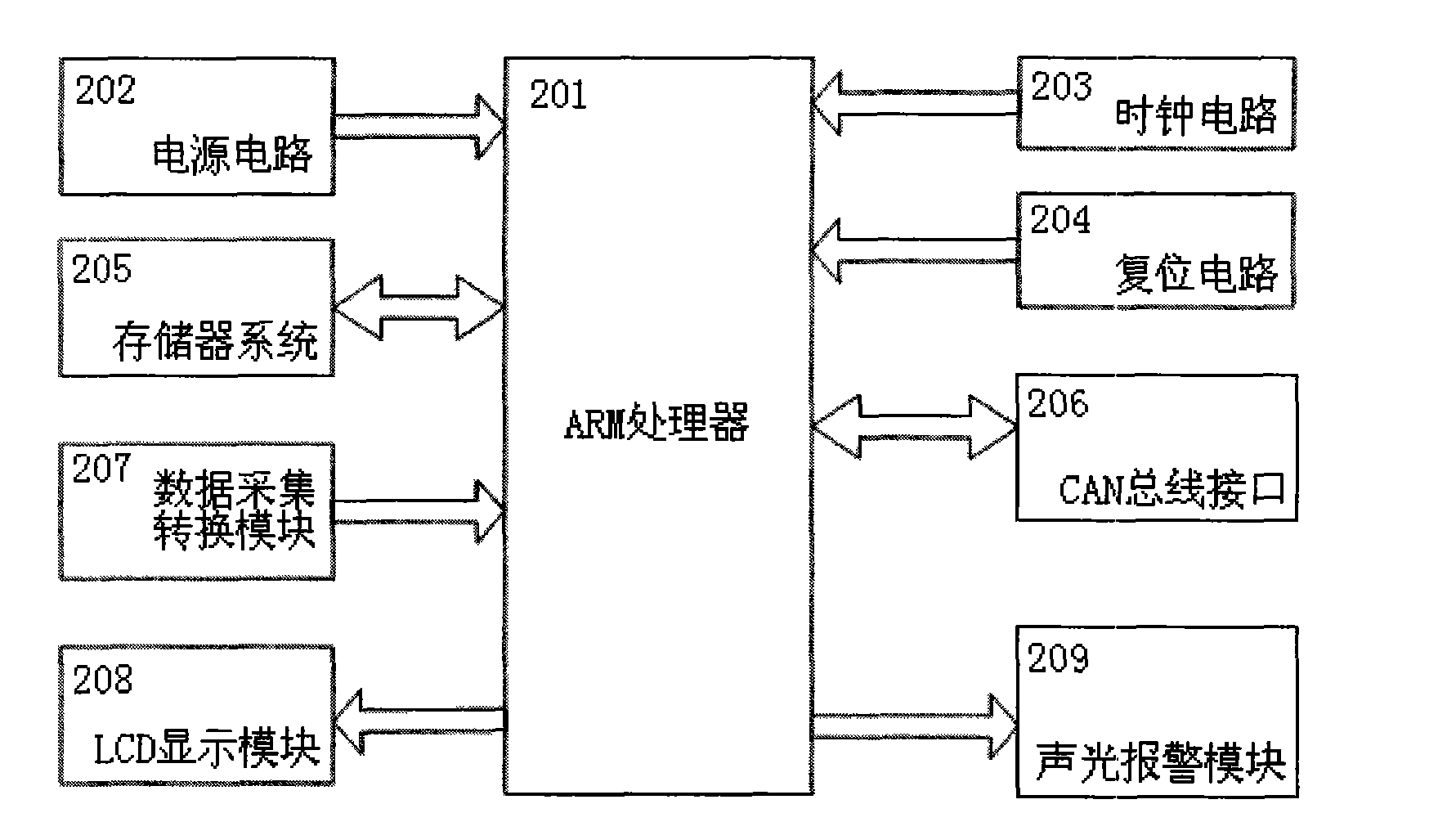

[0019] refer to figure 2 As shown, the monitoring circuit of the water pump motor measurement and control substation 2 includes an ARM processor 201, and the ARM processor 201 is connected with a power supply circuit 202, a clock circuit 203, a reset circuit 204, a memory system 205, a CAN bus interface 206 and The data acquisition and conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com