High-voltage LDMOS device based on BCD process and manufacturing process

A high-voltage and process technology, applied in the field of high-voltage LDMOS devices and manufacturing processes, can solve the problems of low performance and large on-resistance of LDMOS devices, and achieve the effects of reducing on-resistance, small length of withstand voltage region, and improving withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

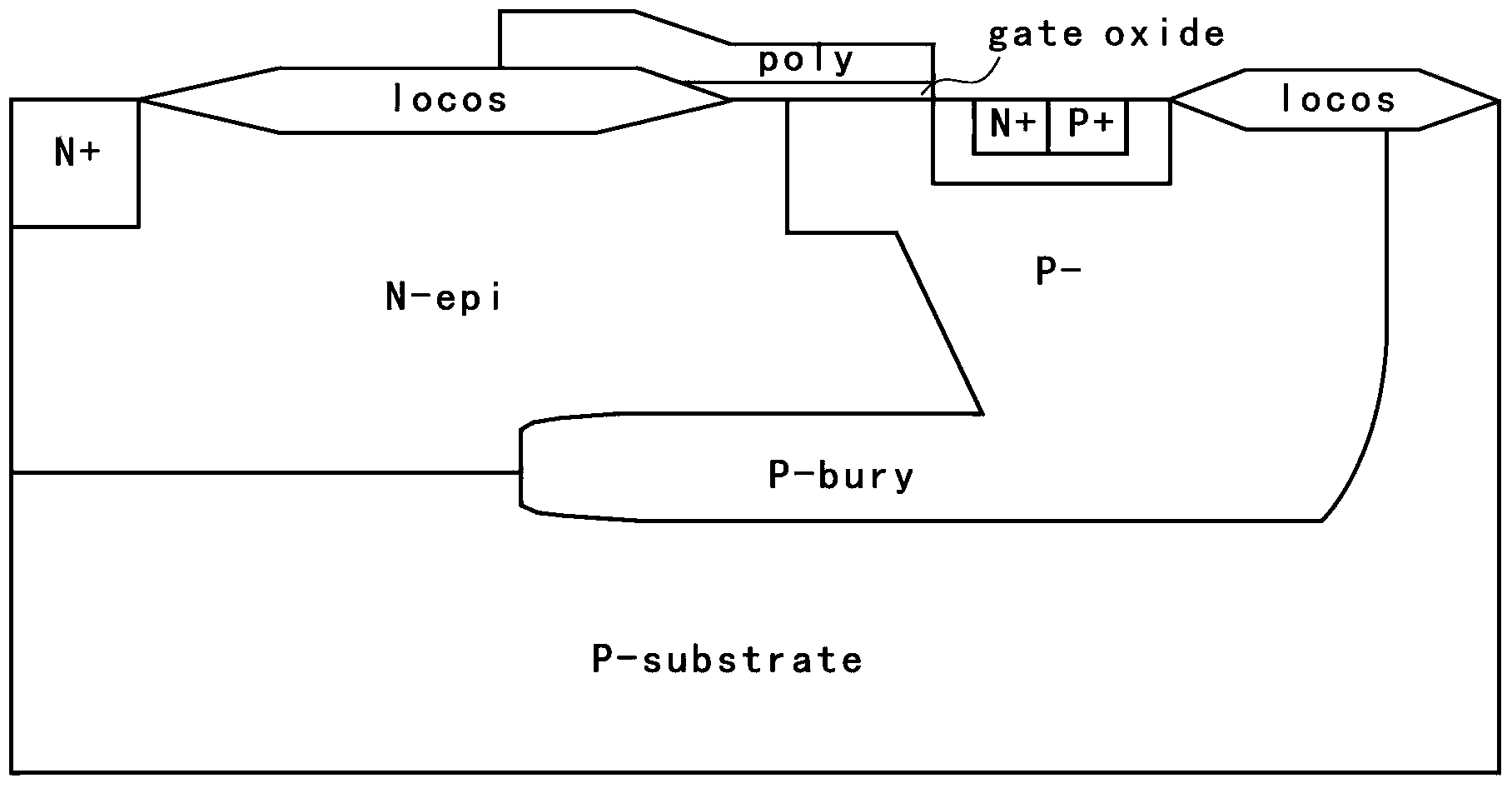

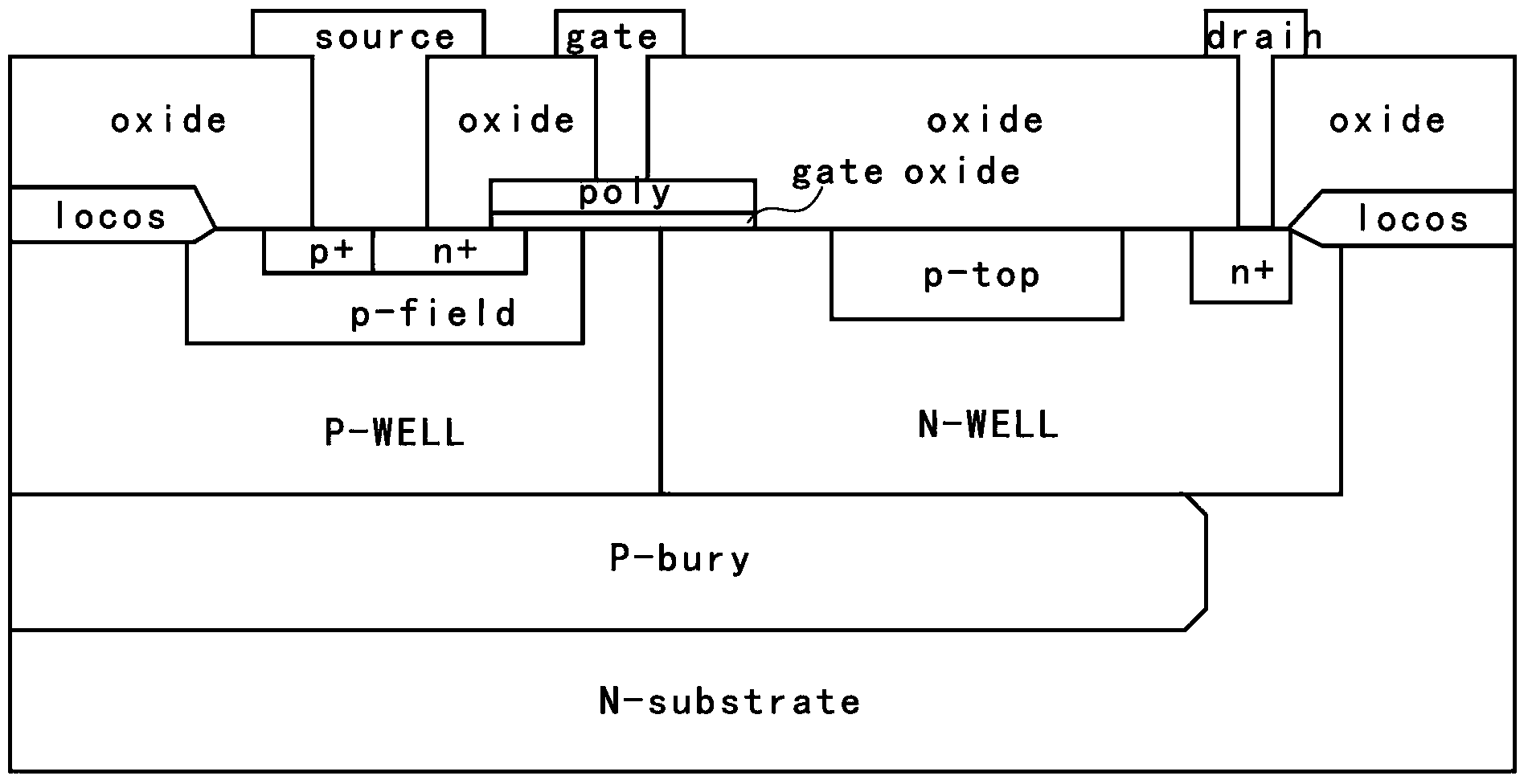

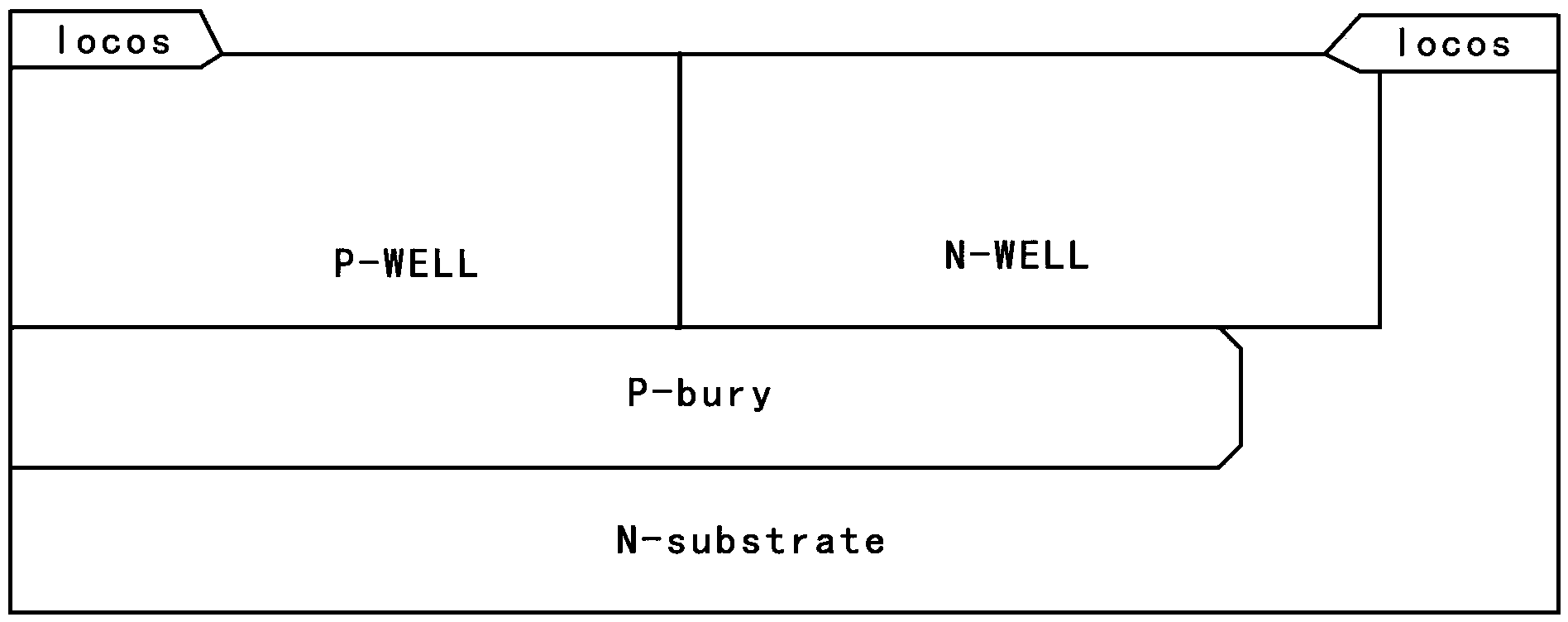

[0027] like figure 2 As shown, the high-voltage LDMOS device based on the BCD process of the present invention includes a substrate, the substrate is an N-type substrate N-substrate, and the N-type substrate N-substrate is a P-type buried layer P-bury, P The N-type thin epitaxial layer is on the buried layer P-bury, the N-well N-well is located on one side of the N-type thin epitaxial layer, and the side of the N-well N-well close to the polysilicon poly is a P-type layer covered by a field oxide layer oxide Lightly doped top layer P-top, the other side is N-type injection layer n+, N-type injection layer n+ extends upward to the drain drain, P well P-well is located on the other side of N-type thin epitaxial layer, P well P- The middle and upper part of the well is the p-type field area P-field, and the p-type field area P-field has short-circuited N-type injection layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com