Sodium ion secondary battery, layered manganese-containing oxide active substance and anode active substance used in sodium ion secondary battery, and preparation method of layered manganese-containing oxide active substance

A technology of active material and manganese oxide, which is applied in the field of layered manganese oxide active material, can solve the problems of poor rate performance, unstable cycle, unstable positive electrode material, etc., and achieve high capacity density, good safety performance, structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example is used to illustrate the preparation and application of the positive electrode active material of the present invention.

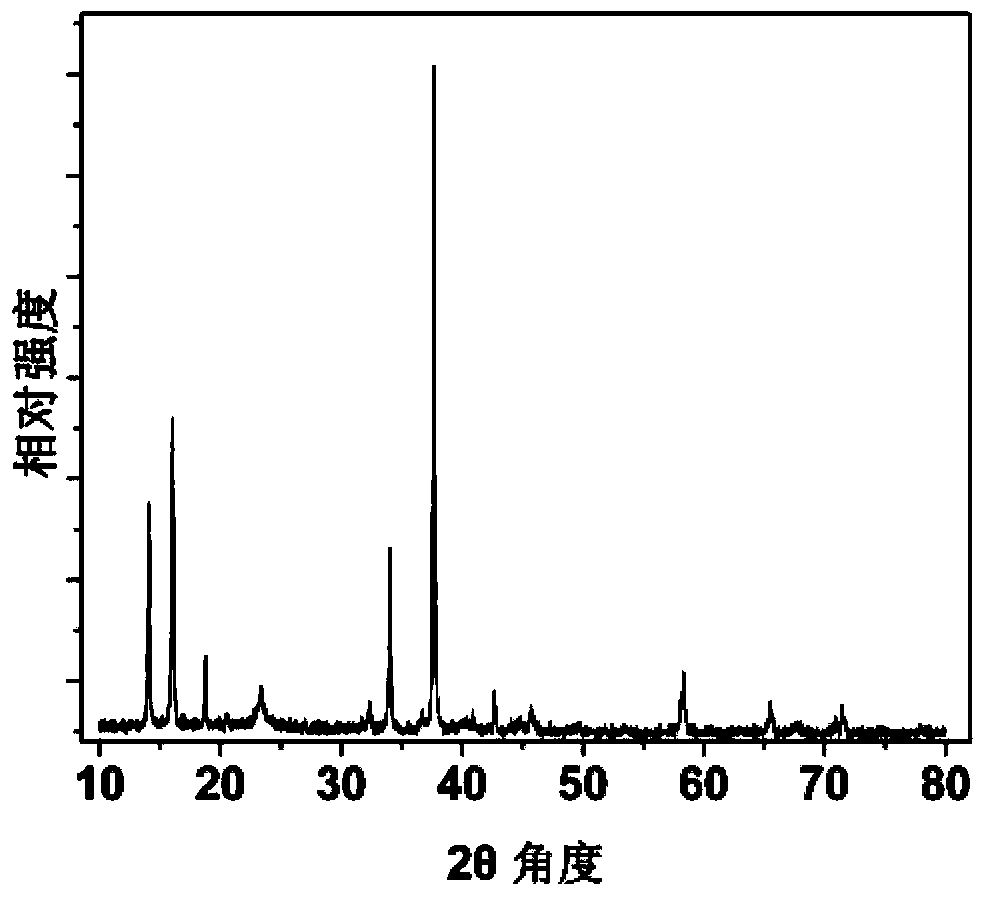

[0033] The present embodiment adopts solid-phase method to prepare active material, and concrete steps are: Na 2 CO 3 (analytical pure), Li 2 CO 3 (analytical pure) and Mn 2 o 3 Mix according to the stoichiometric ratio, mix and grind in an agate mortar for half an hour to obtain the precursor, which is pressed into tablets and transferred to Al 2 o 3 In the crucible, it is processed at 1000 degrees Celsius in a muffle furnace for 24 hours, and the resulting black powder sheet is ground for later use, which is the active substance Na 0.4736 Li 0.03 mn 0.97 o 2 , its XRD pattern is shown in figure 1 ; image 3 is the SEM image of the substance.

[0034] The above active material is used as the positive electrode material to prepare a sodium ion battery. The specific steps are: the prepared active substance Na 0.4736 Li 0....

Embodiment 2

[0036] This example is used to illustrate the preparation and application of the positive electrode active material of the present invention.

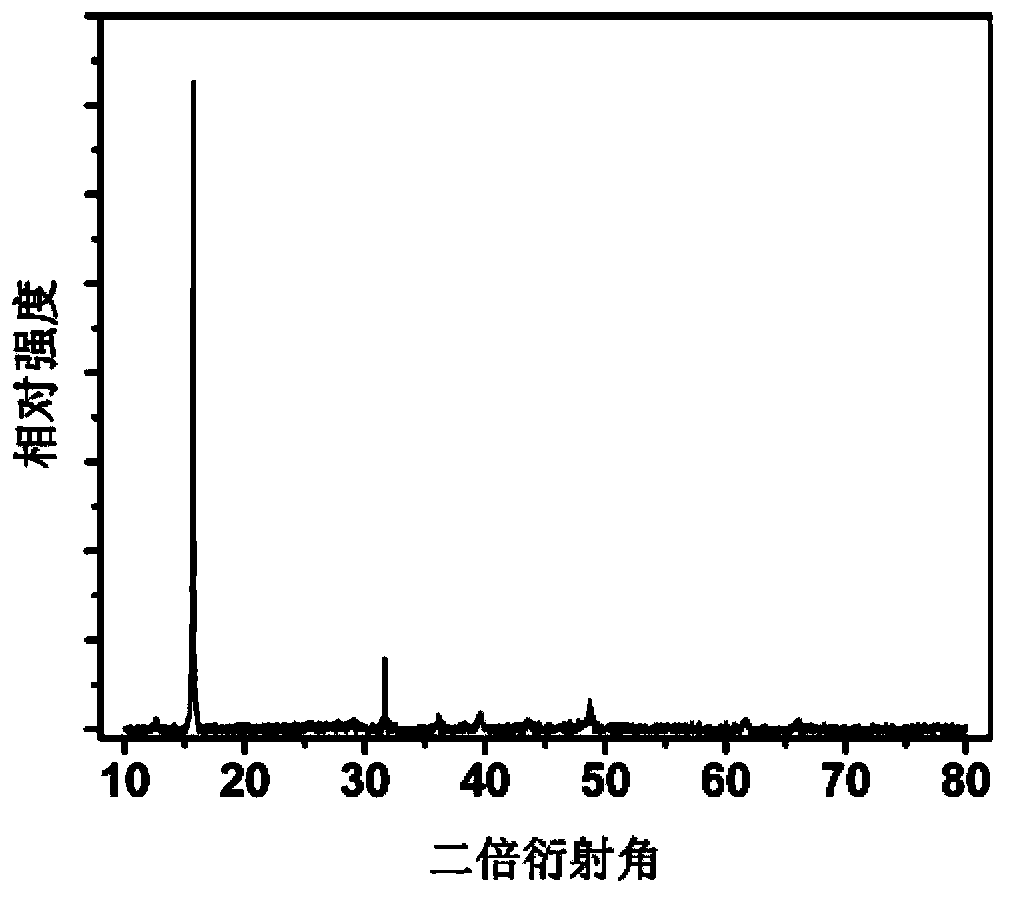

[0037] The present embodiment adopts solid-phase method to prepare active material, and concrete steps are: Na 2 CO 3 (analytical pure), Li 2 CO 3 (analytical pure) and Mn 2 o 3 Mix according to the stoichiometric ratio, mix and grind in an agate mortar for half an hour to obtain the precursor, which is pressed into tablets and transferred to Al 2 o 3 In the crucible, it is processed in a muffle furnace at 1200 degrees Celsius for 24 hours, and the resulting black powder sheet is ground for later use, which is the active substance Na 0.535 Li 0.1228 mn 0.8772 o 2 , its XRD pattern is shown in figure 2 ;

[0038] The above active material is used as the positive electrode material to prepare a sodium ion battery. The specific steps are: the prepared active substance Na 0.535 Li 0.1228 mn 0.8772 o 2 The powder is mixed w...

Embodiment 3

[0040] This example is used to illustrate the preparation and application of the positive electrode active material of the present invention.

[0041] The present embodiment adopts solid-phase method to prepare active material, and concrete steps are: Na 2 CO 3 (analytical pure), Al 2 o 3 with Mn 2 o 3 Mix according to the stoichiometric ratio, mix and grind in an agate mortar for half an hour to obtain the precursor, which is pressed into tablets and transferred to Al 2 o 3 In the crucible, it is processed in a muffle furnace at 1200 degrees Celsius for 24 hours, and the resulting black powder sheet is ground for later use, which is the active substance Na 0.767 al 0.1667 mn 0.8333 o 2 , its XRD pattern is shown in figure 2 .

[0042] The above active material is used as the positive electrode material to prepare a sodium ion battery. The specific steps are: the prepared active substance Na 0.767 al 0.1667 mn 0.8333 o 2 The powder is mixed with acetylene blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com