Temperature-regulating energy-saving life-prolonging power supply socket of electric soldering iron

An electric soldering iron and socket technology, which is applied in the fields of electronic technology and temperature control, can solve problems such as power reduction of electric soldering iron, and achieve the effects of simple circuit, stepless temperature adjustment, and guaranteeing reasonable melting flow and welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

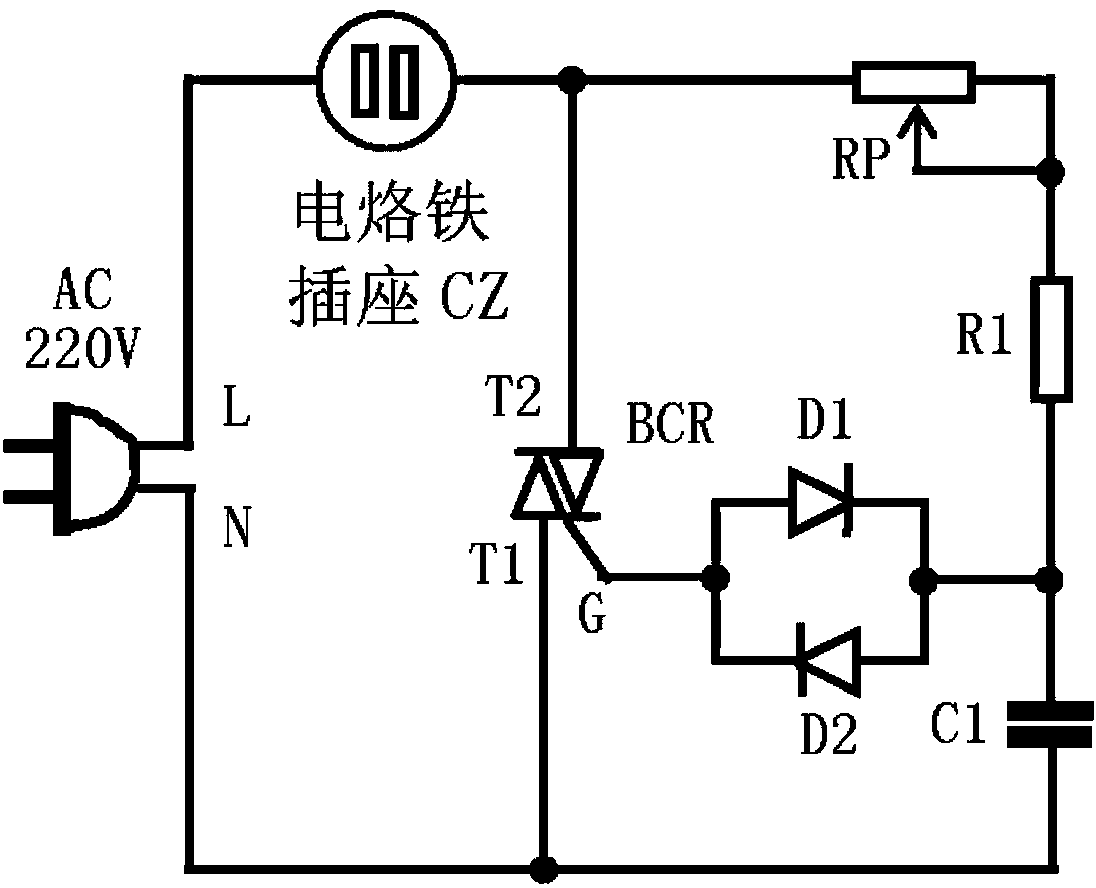

[0013] According to attached figure 1 The electric soldering iron temperature adjustment, energy saving, life extension power socket circuit working principle diagram and accompanying drawings are shown, and the connection relationship between the components in each part of the circuit described in the summary of the invention, and the technical parameter requirements of the components described in the implementation mode The present invention can be realized by implementing the main points of circuit making, and the related technologies of the present invention will be further described below in conjunction with the embodiments.

[0014] Technical parameters of components and their selection requirements

[0015] D1~D2 are the trigger diodes, the selected model is 1N4004 silicon rectifier diode;

[0016] BCR is a bidirectional thyristor, and the selected model is 3CTSI or DB3;

[0017] The resistance is RTX-1 metal film resistor with a power of 1W, and the resistance value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com