Stepless compensating device and method

A compensation device and stepless technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of low cost performance and large user investment, and achieve the effects of high cost performance, accelerated response speed, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

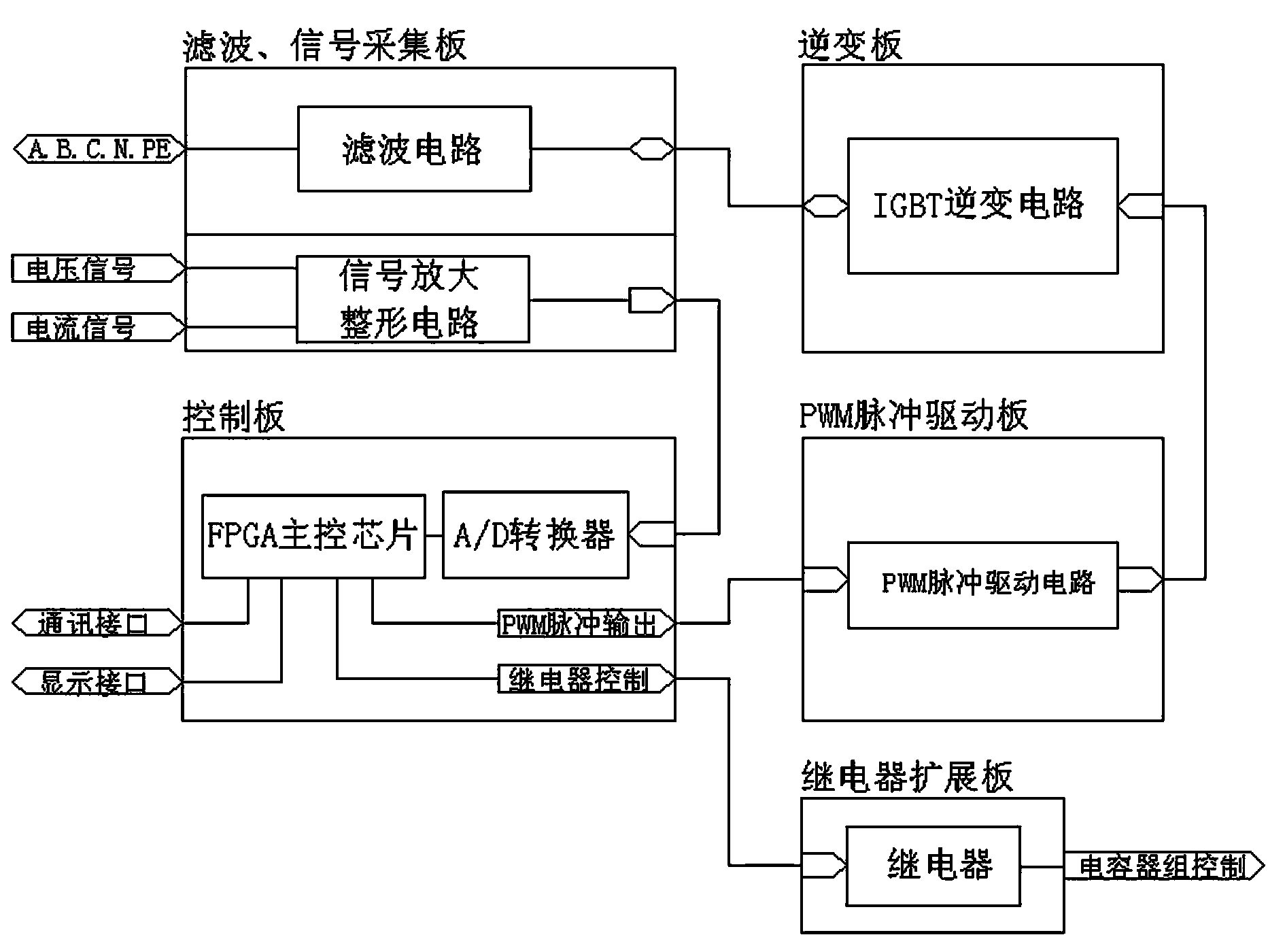

[0034] like figure 1 , figure 2 As shown, a stepless compensation device is mainly composed of the following components:

[0035] Filtering and signal acquisition board: it is mainly composed of a filter circuit and a signal amplification and shaping circuit. Used to receive the grid voltage signal and current signal and amplify and shape the signal;

[0036] Inverter board: mainly composed of IGBT inverter circuit, connected with filter circuit, used for the conversion between DC and AC;

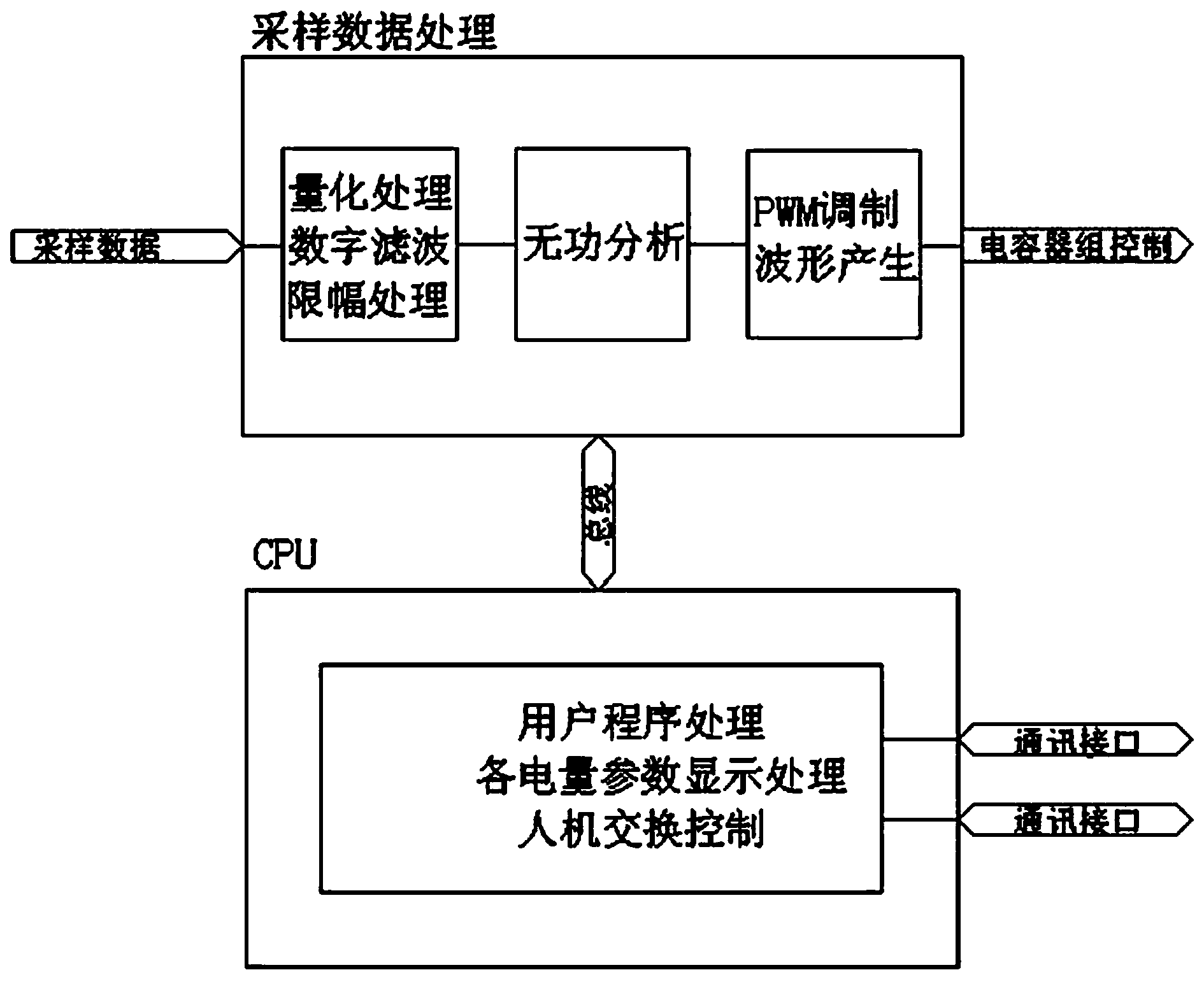

[0037] Control board: mainly composed of FPGA main control chip, the FPGA main control chip is also connected to the A / D conversion chip, the A / D conversion chip is connected to the signal amplification and shaping circuit, and the control board is used to receive voltage and current signals And output commands to send control information;

[0038] PWM pulse drive board: mainly composed of PWM pulse drive circuit, connected with FPGA main control chip and IGBT inverter circuit, used to...

Embodiment 2

[0042] In order to better realize the present invention, it is convenient to switch to other equipment when reaching the set capacity, such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a relay expansion board, the relay expansion board is mainly composed of relays, and the relays are connected to the FPGA main control chip. When the reactive power of the load is greater than the set compensation capacity of the compensation device, by using the relay output, other compensation equipment can be used to reduce the output current of the compensation device. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] In order to better realize the present invention, this embodiment is based on Embodiment 2, and the relay is also connected to the capacitor bank. By adopting the way of connecting the relay and the capacitor bank, the capacitor bank can be used as a group switching, and the output reactive capacity can realize the connection between the device and the traditional equipment, thereby increasing the scope of application of the device. Other parts of this embodiment are the same as those of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com