Acoustic structure with passive vibrating diaphragm unit

A passive diaphragm and acoustic structure technology, applied in the transducer shell/cabinet/stand and other directions, can solve the problems of limited speaker design and inability to take into account the acoustic performance of the speaker system, and achieve good bass effect, low vibration, good application sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

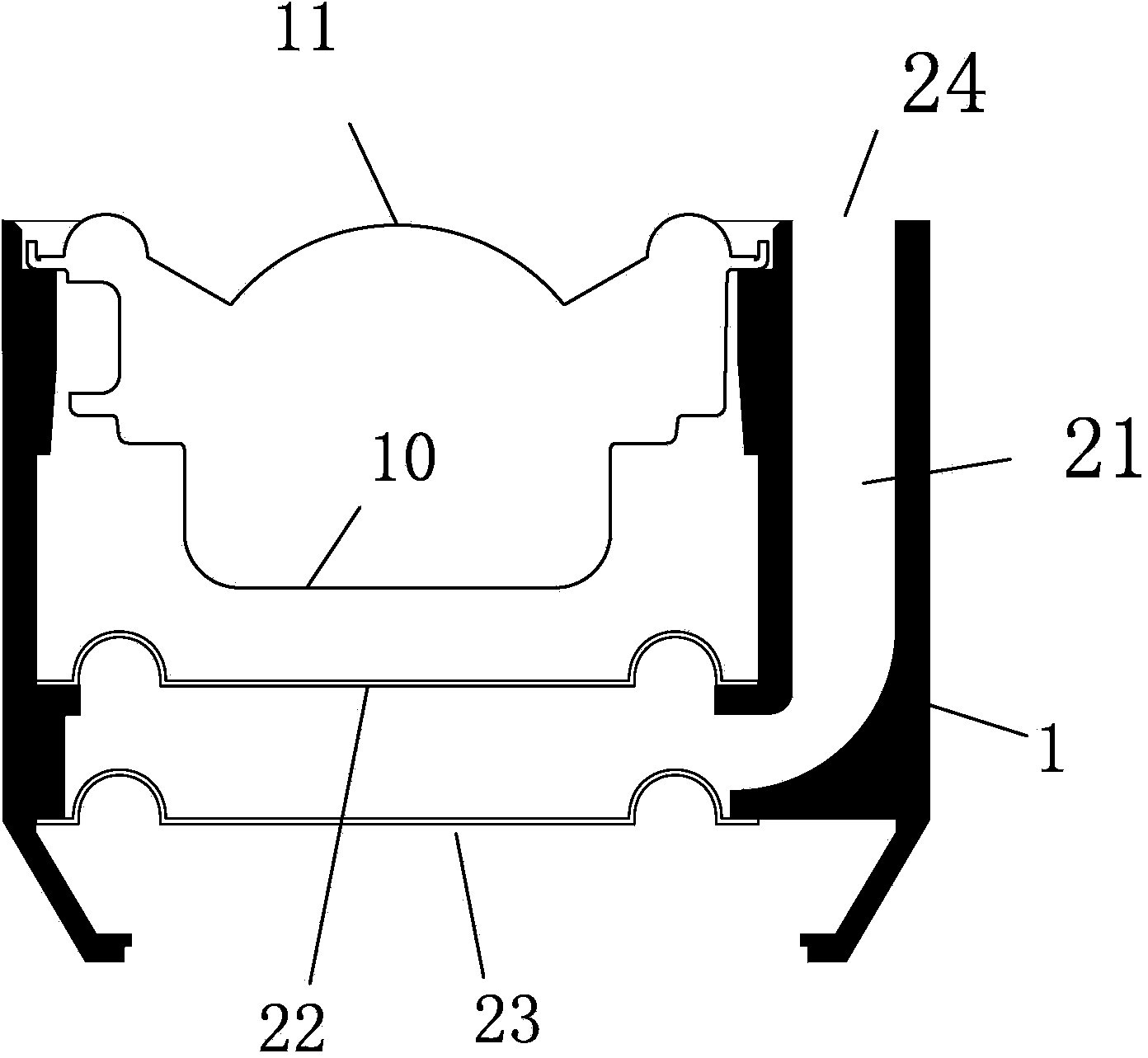

[0066] Such as figure 1 , the present embodiment provides an audio radiation module, which includes an annular casing 1; a speaker unit 10, the speaker unit 10 is installed in the annular casing 1, and the sound cone 11 of the speaker unit 10 is connected to the annular The shell 1 is connected and exposed to the air environment; there is a radiation port 24 on the side of the circular shell 1 connected to the sound cone 11 of the speaker unit 10; the radiation port 24 is located on the surface of the sound cone 11 of the speaker unit 10 Periphery; Passive diaphragm unit 22 and 23, described passive diaphragm unit 22 and 23 are positioned at the rear of described loudspeaker unit 10, coaxially placed with described loudspeaker unit 10; Described passive diaphragm unit 22 and 23 and annular The shells 1 are connected by elastic rings 221 and 231 . The side of the speaker unit 10 is provided with a radiation pipe 21 , and one end of the radiation pipe 21 is connected to the rad...

Embodiment 2

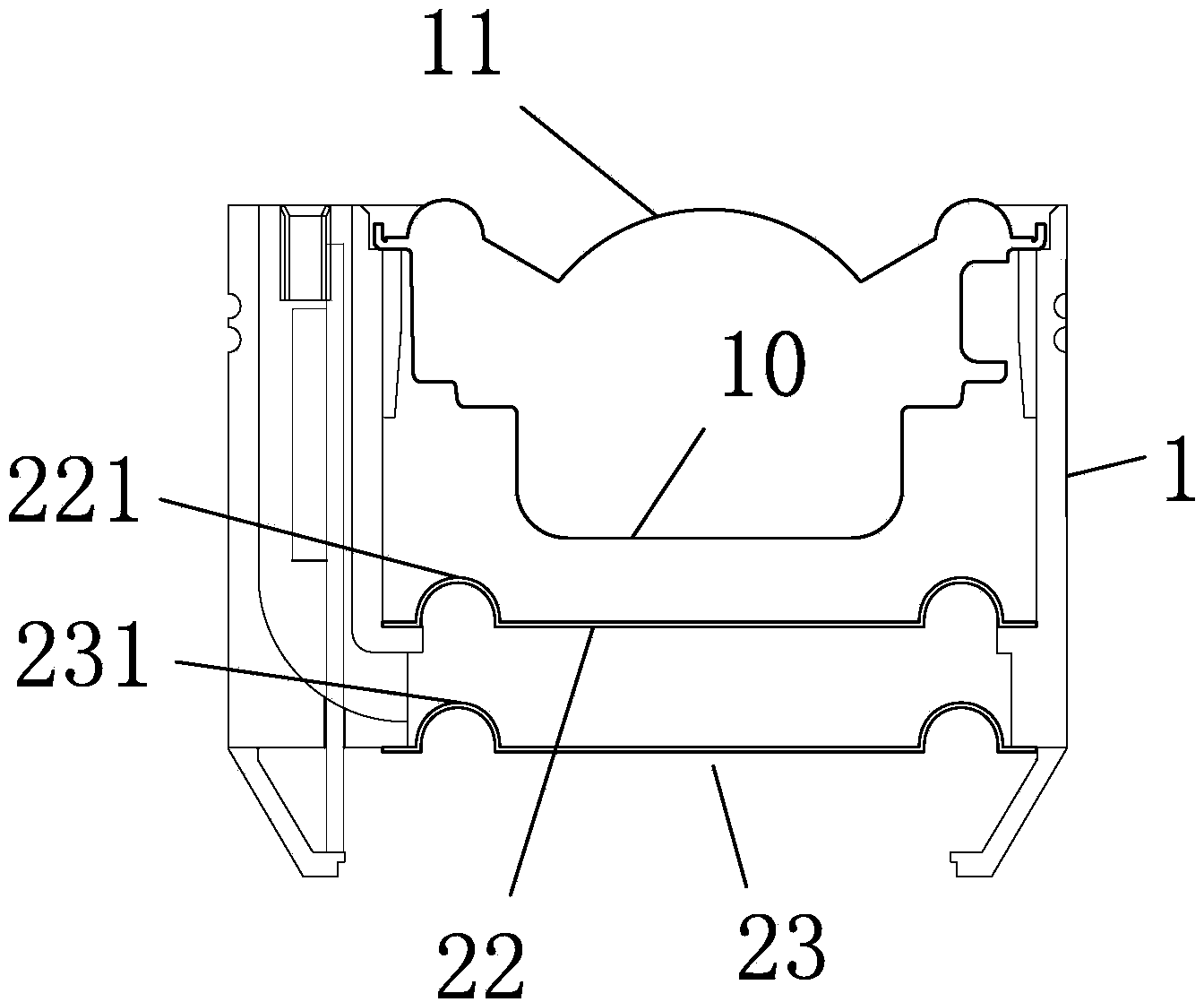

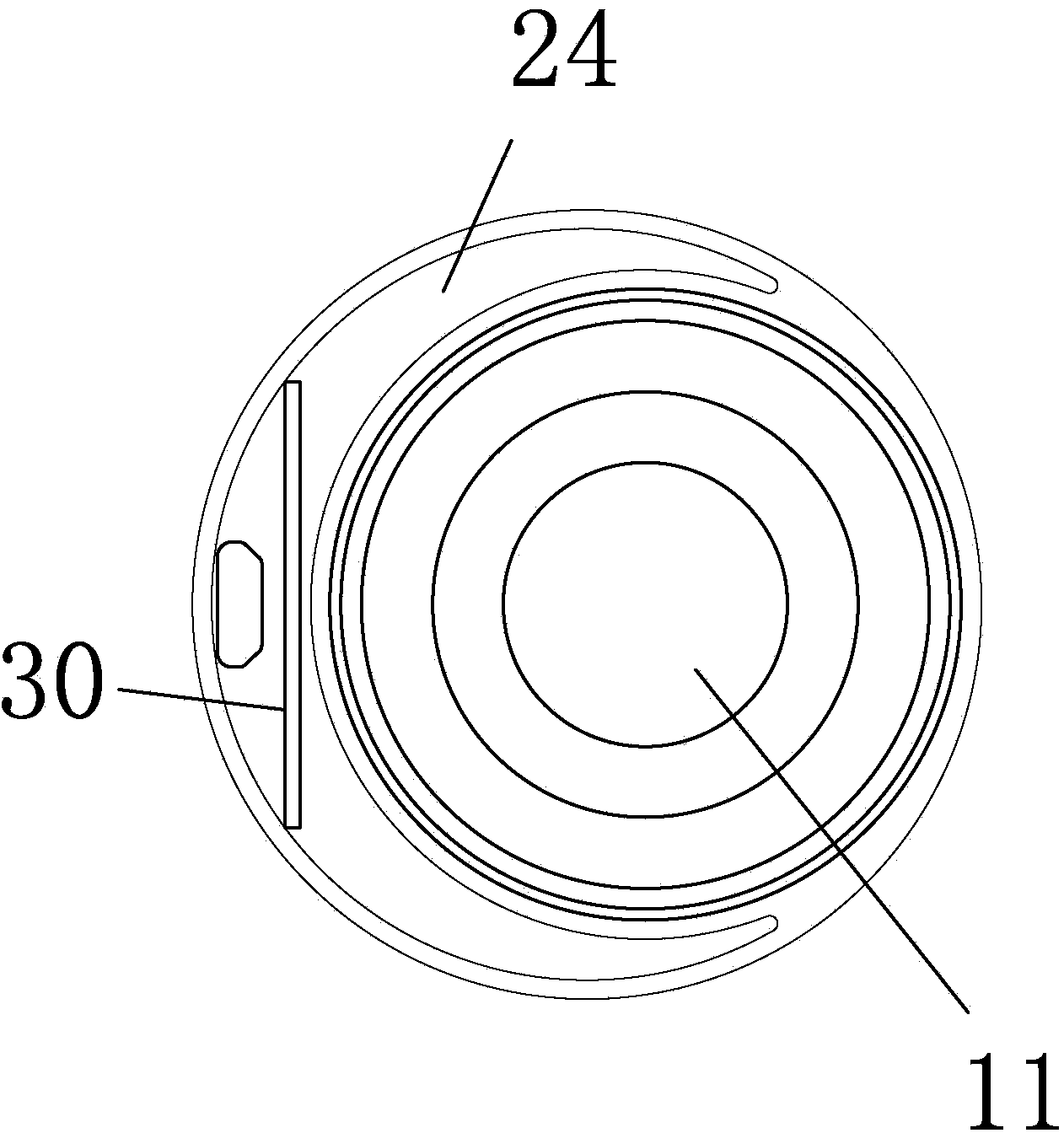

[0073] refer to figure 2 , image 3 , the structure of this embodiment is similar to that of Embodiment 1, the difference is that the cross-section of the radiant tube 21 of this embodiment is "C"-shaped, covering the outer periphery of the cross-section of the sound cone 11, which is helpful for the speaker unit 10 side The circuit board 30 is hidden, so that various active module solutions, such as amplifiers, frequency dividers, etc., can be constructed.

[0074] The passive diaphragm unit of this embodiment and the elastic rings connected between 22, 23 and the annular shell 1 have structures in the same direction, as Figure 8 As shown, the directions of the elastic rings 221 and 231 are the same; in actual situations, the elastic force of the elastic rings 221 or 231 is not equal when the radiating unit 22 or 23 goes up or down respectively, and this structure makes the passive diaphragm units 22 and 23 irrespective of Whether it is expansion or contraction, the elast...

Embodiment 3

[0076] Such as Figure 4 As shown, the three-dimensional schematic view of the shell of the second embodiment of the present invention.

[0077] The structure of the present embodiment is similar to that of the first embodiment, the difference is that the cross-sectional area of the radiant tube 21 of the second embodiment is constant, and it is a pipeline of the same diameter, while the radiant tube 21 of the present embodiment is connected to the atmosphere from the end The radiation opening 24 has an expanding edge 29, making it a gradually expanding shape. The radiant tube 21 of this form has the characteristics of small acoustic resistance, and at the same time has the effect of amplifying the sound waves it collects, further improving the sound generation performance of the whole module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com