Water-cooling heat dissipation electromagnetic heating device and control method thereof

An electromagnetic heating device, water cooling and heat dissipation technology, applied in the direction of electric heating fuel, coil device, induction heating, etc., can solve the problems of difficulty in ensuring heat dissipation performance, affecting heat dissipation effect, difficult heat dissipation, etc., and achieves saving in operating costs and energy consumption, saving The effect of equipment investment and large winding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

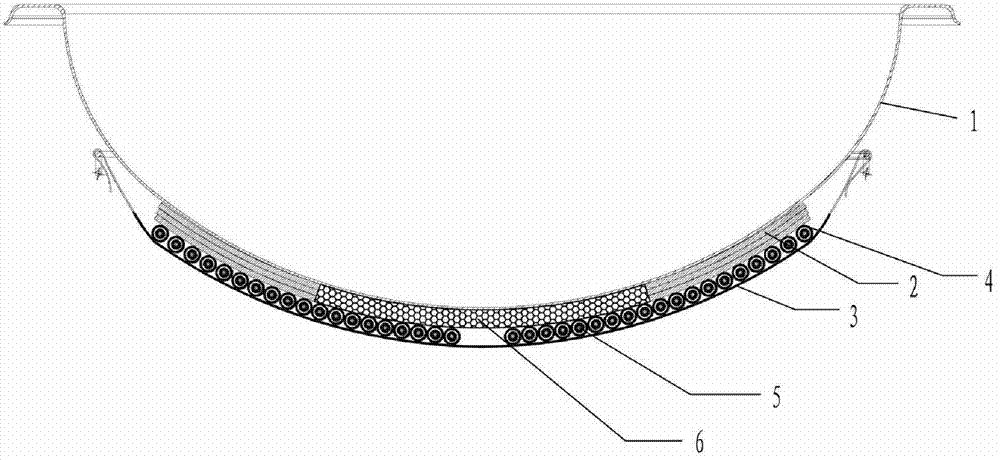

[0063] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

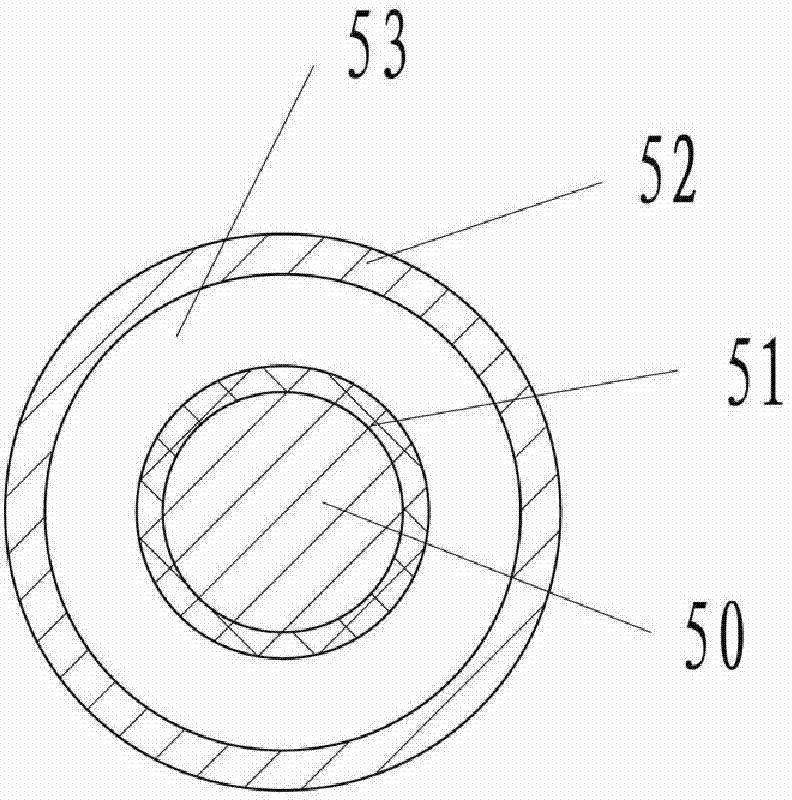

[0064] Such as figure 1 As shown, the electromagnetic heating induction coil can be formed by winding a wire with a water-cooled sleeve, and the wire with a water-cooled sleeve is composed of a metal wire 50 coated with an insulating layer 51 and then covered with a guide tube 52, wherein the guide tube 52 can be heat-conducting silicone The channel 53 between the guide tube 52 and the insulating layer 51 is a water flow channel.

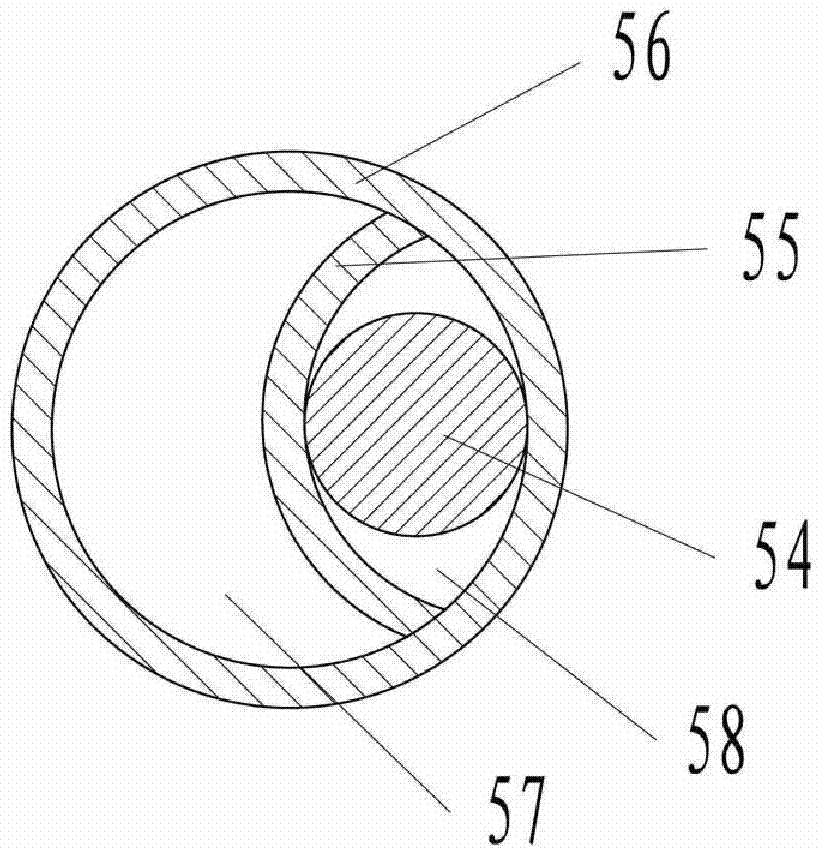

[0065] Such as figure 2 The wire with a water-cooling sleeve shown is composed of a metal wire 54 sheathed with a guide tube 56, wherein the guide tube 56 can be a heat-conducting silicone tube, and the inside of the guide tube 56 is provided with the same quality as the guide tube and connected with the guide tube. An integrated partition wall 55 , the partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com