Versatile self-walking corn green feed harvester

A green forage harvester, self-propelled technology, applied in the field of crop harvesting and green forage harvester, can solve the problems of unreasonable power transmission design, inability to operate functional parts at the same time, unstable power transmission and other problems of corn green forage harvester, and achieve complete functions , Reduce the occupied space, and the effect of stable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

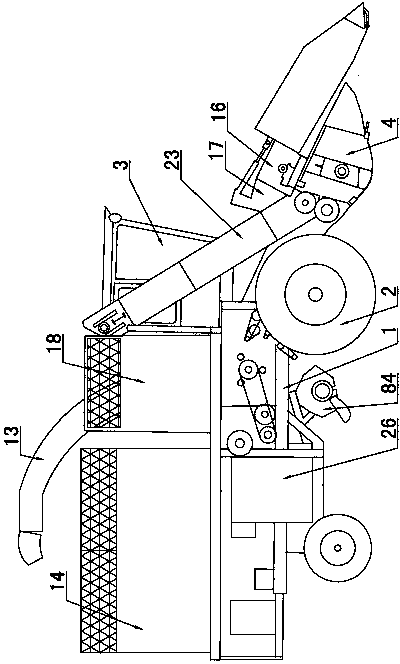

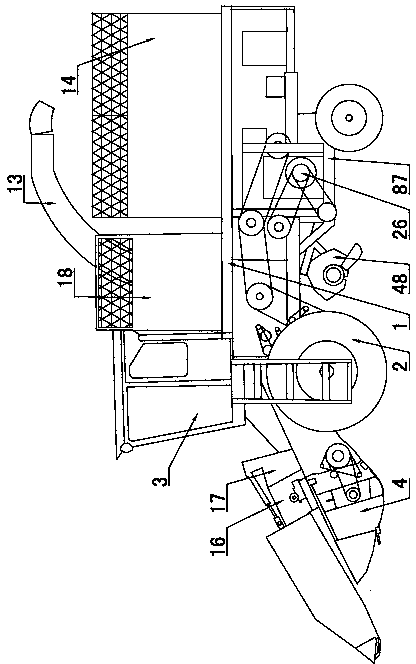

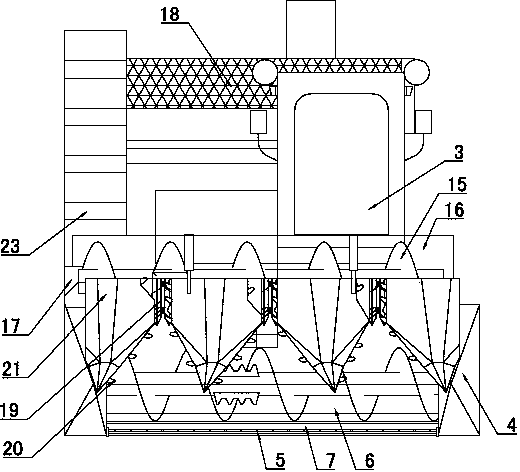

[0027] Refer to attached Figure 1~4 : This all-round self-propelled corn green forage harvester includes a frame 1 and wheels 2, a power transmission system and a cab 3 are installed on the frame 1, a harvesting device is installed at the front end of the frame 1, and the rear of the harvesting device is connected to a crop conveying device and Straw shredding and conveying device, the field return machine 84 is installed on the lower part of the frame 1, the crop storage bin 18 and the straw storage bin 14 are installed at the rear of the driver's cab 3 and above the power transmission system, and the crop conveying device is connected to the crop storage bin 18, and the straw The shredding conveying device is connected to the straw storage bin 14 .

[0028] The harvesting device includes a lower header 4 and a detachable upper header. A hob 5, a roller shaft 7 and a feeding auger 6 are installed horizontally in the lower header 4. The rear portion of the lower header 4 has ...

Embodiment 2

[0041] Refer to attached Figure 6According to different needs of customers, this all-round self-propelled corn green fodder harvester may not install the returning machine 84 in the lower part. The power transmission system now comprises engine 26, and engine 26 side installs travel output pulley 63 and work output pulley 64, and clutch is installed between travel output pulley 63 and work output pulley 64. The walking output pulley 63 drives the front wheel walking device to realize walking, and the working output pulley 64 drives the harvesting and crop conveying transmission device and the straw chopping conveying transmission device to realize operation. Specifically, the work output pulley 64 is connected to the pulley 65, and the pulley 65 is coaxially connected to the right bridge driving pulley 67 through the right crossing bridge 66, and the right crossing bridge driving pulley 67 drives the shredder wheel 68. Right crossing bridge 66 installs right crossing bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com