honey shaker

A technology of honey shaker and honey bucket, which is applied in the field of honey shaker, can solve the problems of unreliable performance, low work efficiency, cumbersome operation process, etc., and achieve the effect of reliable performance, flexible structure, light weight and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

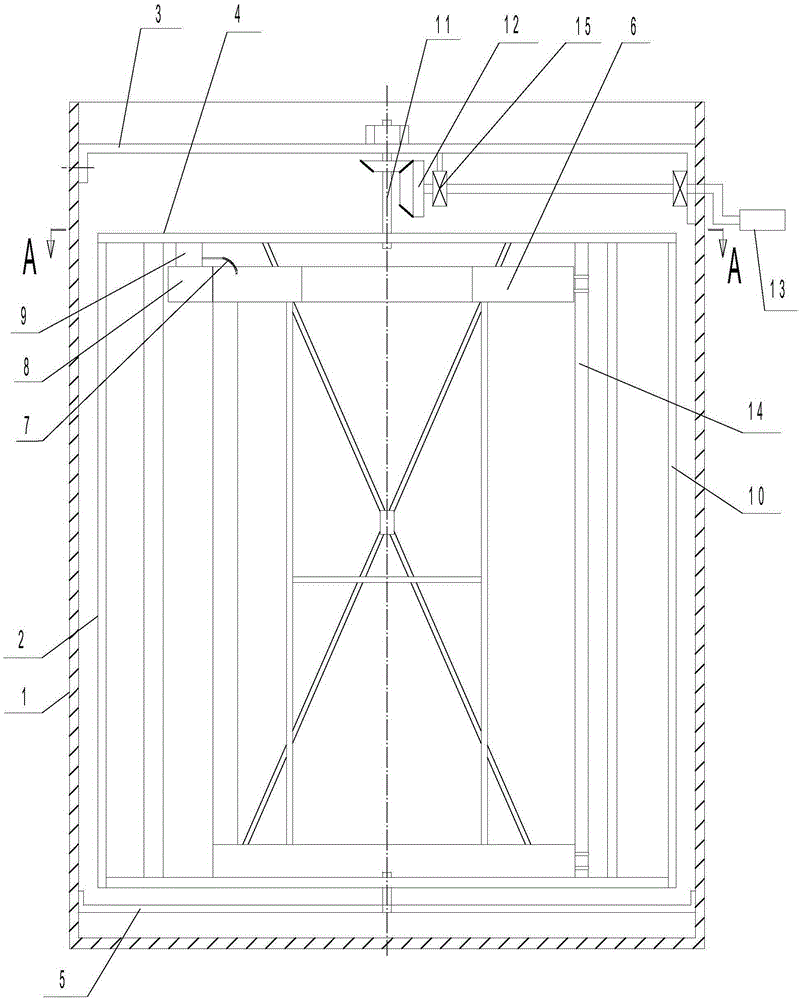

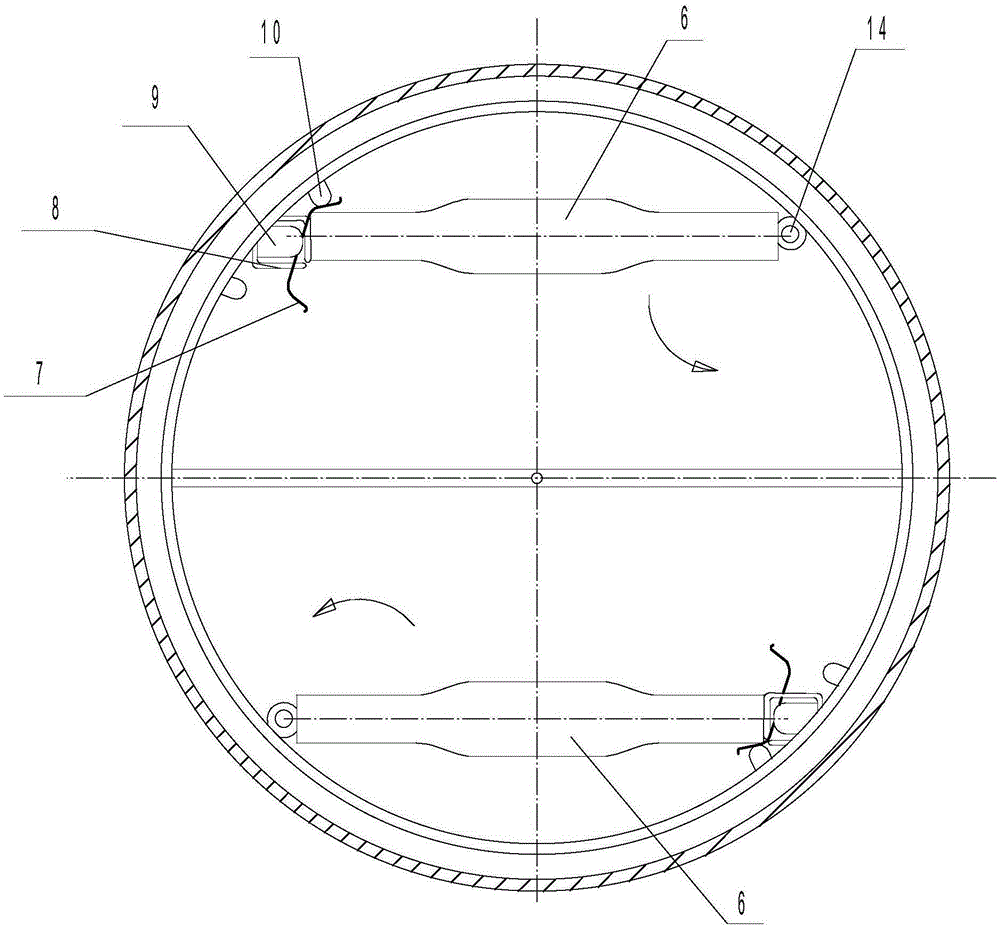

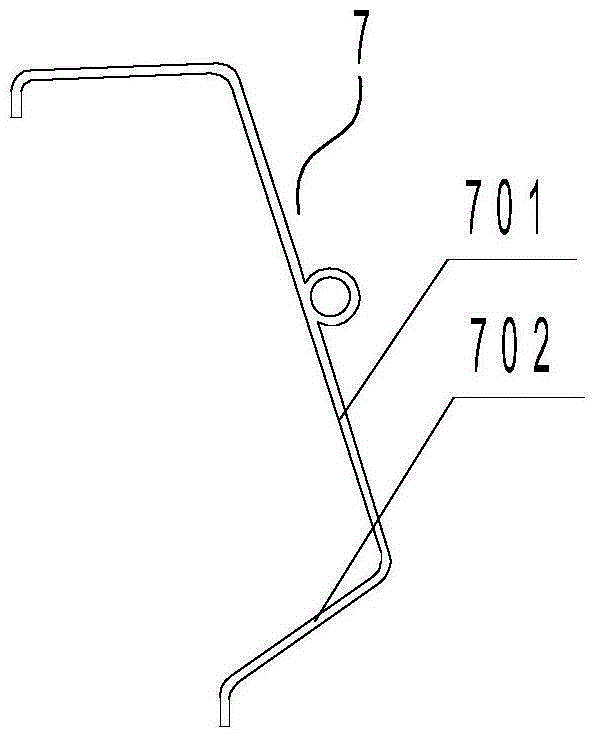

[0028] A honey shaker, such as Figure 1 ~ Figure 2 As shown, it includes a power unit, a honey shaker bucket 1, a transmission device located in the honey shaker bucket, a honey shaker frame 2, a beam 3, an upper beam 4 of the honey shaker frame, a lower beam 5 of the honey shaker frame, and a Two nest frame baskets 6, the two ends of the beam 3 are fixed on the barrel walls on both sides of the top of the honey bucket 1, the two ends of the upper beam 4 on the honey shaker frame are fixedly connected with the top of the honey shaker frame 2, and the honey shaker frame The two ends of lower beam 5 are respectively fixed on the honey bucket barrel wall shaking honey frame 2 below, and the middle part of shaking honey frame lower beam 5 is connected with the bottom of shaking honey frame 2 by pin shaft positioning. The two ends of the upper beam 4 of the shaker frame and the lower beam 5 of the frame are respectively fixed on the top and the bottom of the frame 2, and a main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com