Spherical particle parent nucleus automatic preparation machine

A technology for automatic preparation of spherical particles, applied in the field of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

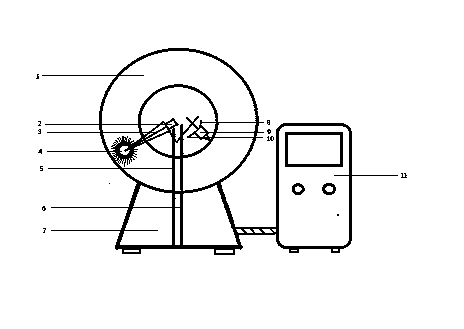

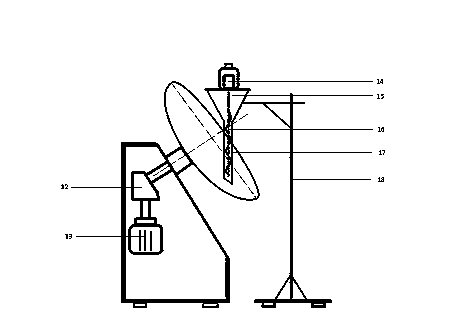

[0015] figure 1 and figure 2 The automatic preparation machine for the spherical particle mother nucleus shown has an adjustable-speed spheronizing device, a binder spraying and atomizing device, a powder quantitative supply device, a particle generating device and an automatic control device.

[0016] Put a certain amount of raw material powder on the bottom of the water chestnut type rolling barrel, turn on the main motor, and drive the rolling barrel to rotate clockwise at a low speed. In the initial stage of preparation, the rolling barrel maintains a low speed of 5-10 rpm. After the belt particles are basically formed, set Set a high speed to make the particles round into a spherical shape. Turn on the spray gun, keep the spray pressure at 0.05-0.2MPa, spray the adhesive evenly on the inner wall of one side of the drum, control the flow rate of the adhesive at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com