Special tension clamp for milling of blade type parts

A part and milling technology, which is applied in the field of special tensioning fixtures for blade parts milling, can solve the problems of inability to accurately control the prestress, and achieve the effects of improving cutting stability, reliable action, and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

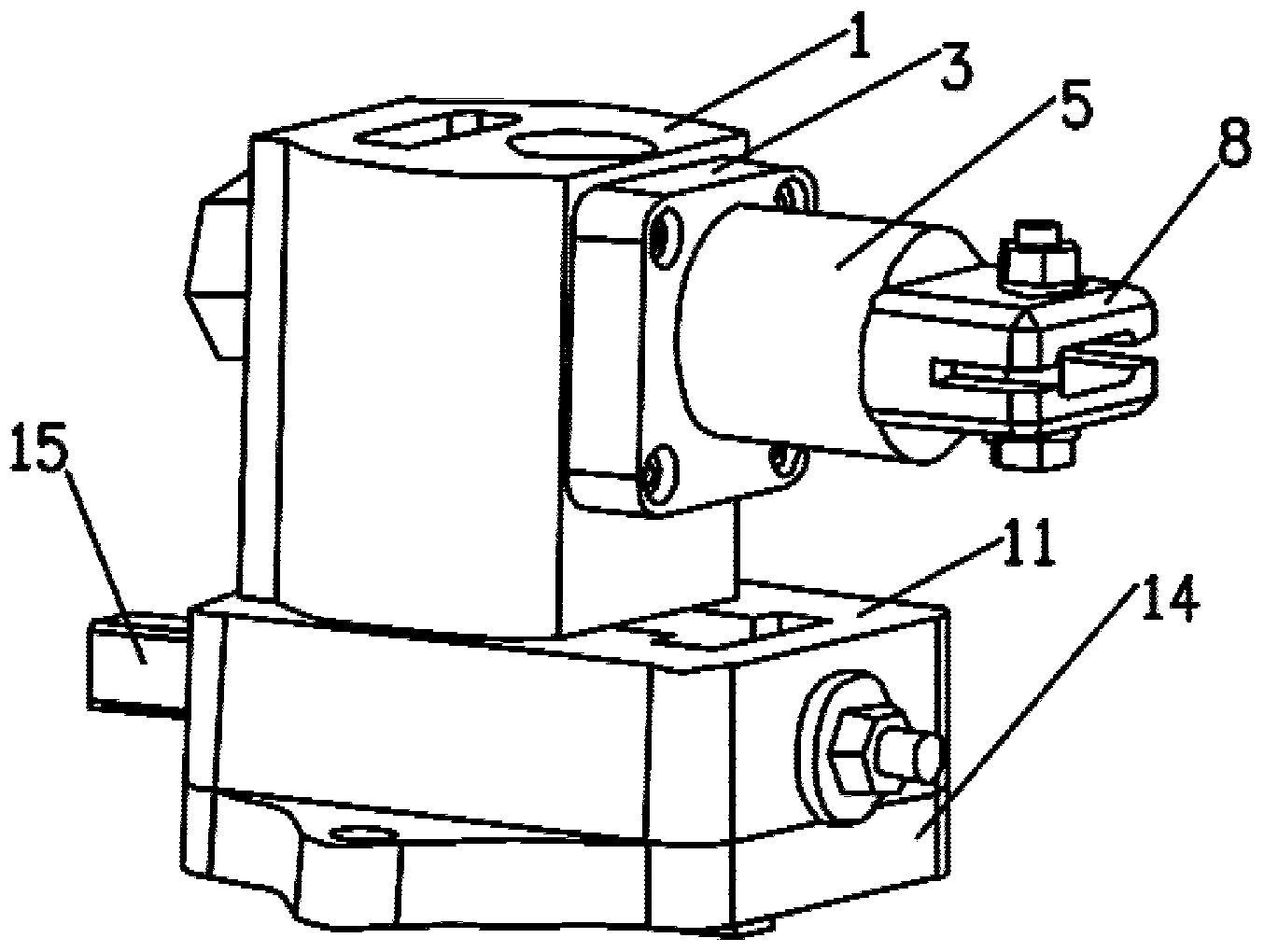

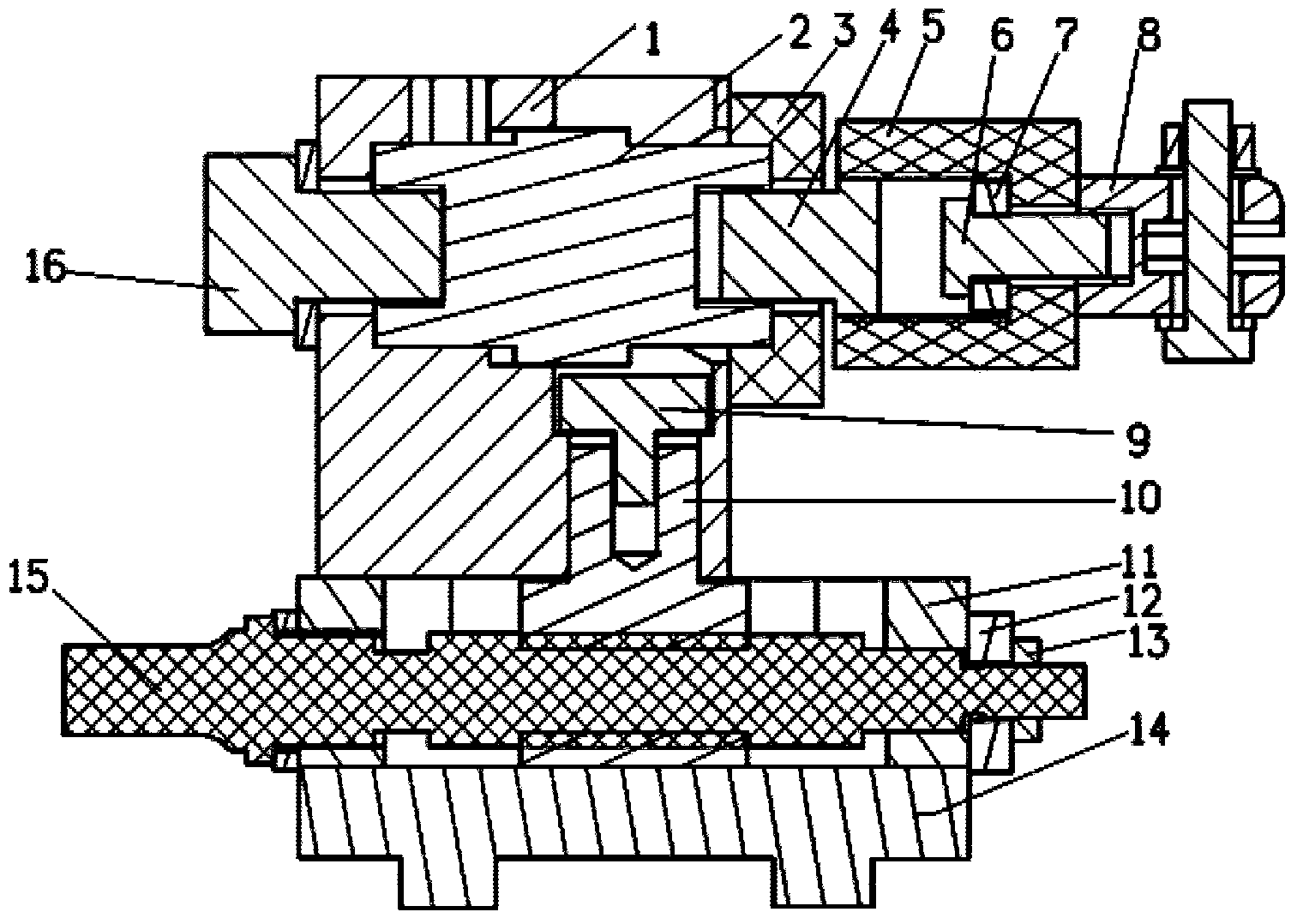

[0030] This embodiment is a special tensioning fixture for milling blade parts, which is suitable for clamping blade parts on a four-axis milling machine.

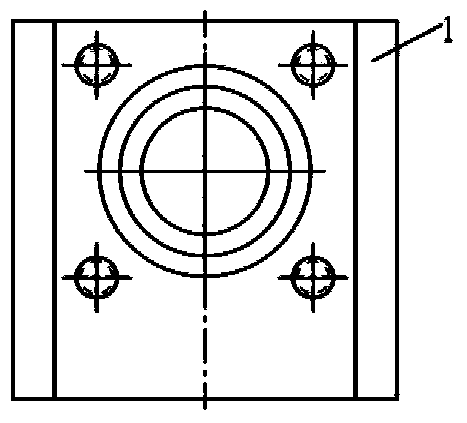

[0031] refer to Figure 1-Figure 18 , the special tensioning fixture for milling blade parts of the present invention is composed of a base, a fixed clamp body, a mobile measurement adjustment device, and a clamping mechanism. The fixed clamp body is installed on the base, and the mobile measurement adjustment device is located on the fixed clamp body. The clamping mechanism It is fixed on the side of the mobile measurement and adjustment device, and is installed parallel to the vertical plane of the fixed clamp body, and the base is fixed on the workbench. The fixed clip body includes a clip body 11, a lead screw 15, a sliding nut 10, a thrust bearing 12, and a lock nut 13. The middle of the clip body 11 is provided with a locking slot along the axial direction, and there are through holes at both ends of the clip body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com