Chinese-style tile production die

A technology of small blue tiles and molds, which is applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and poor product quality, so as to reduce labor intensity, high-quality finished products, and low-quality products. The effect of reducing product rate or scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

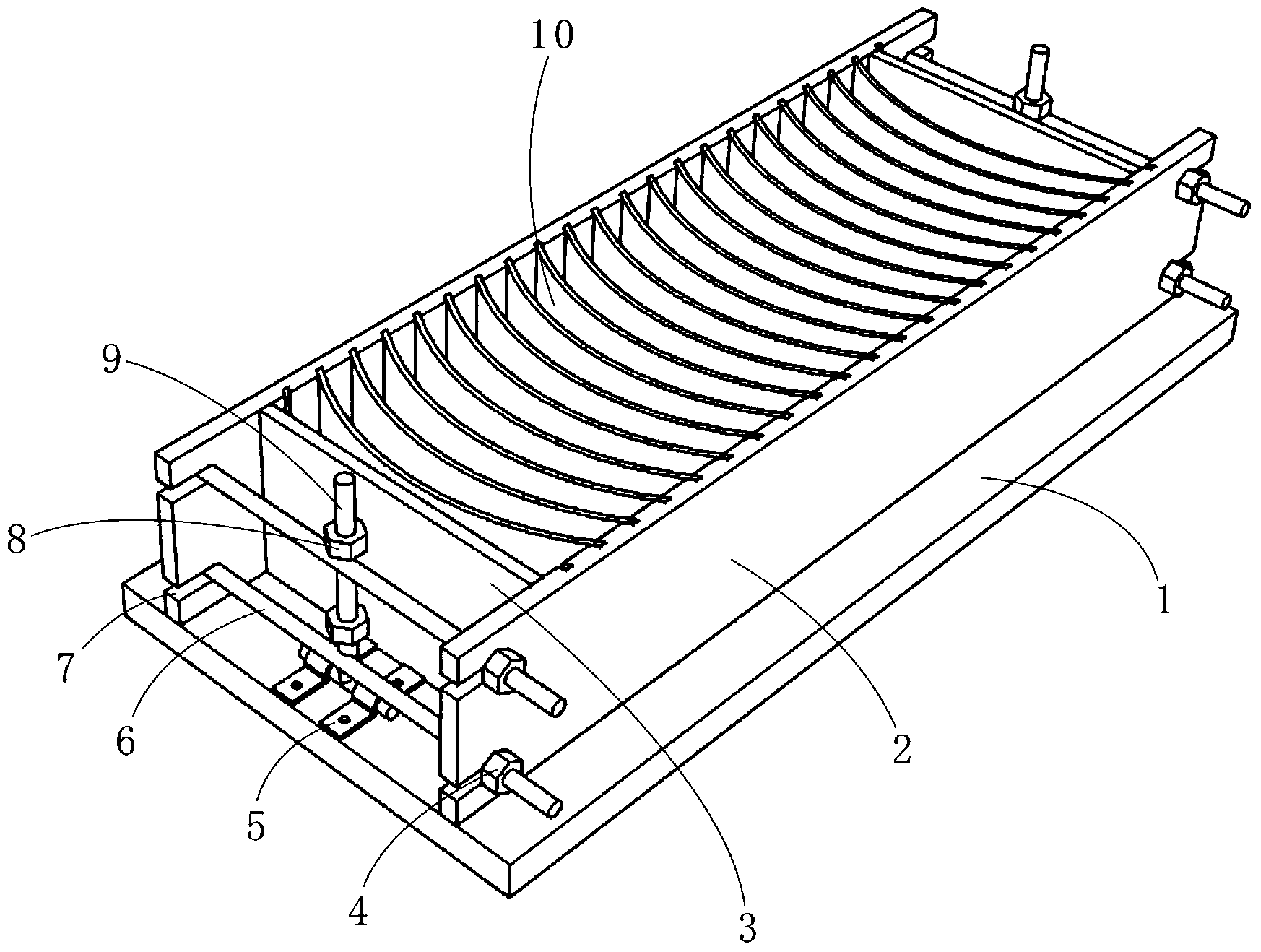

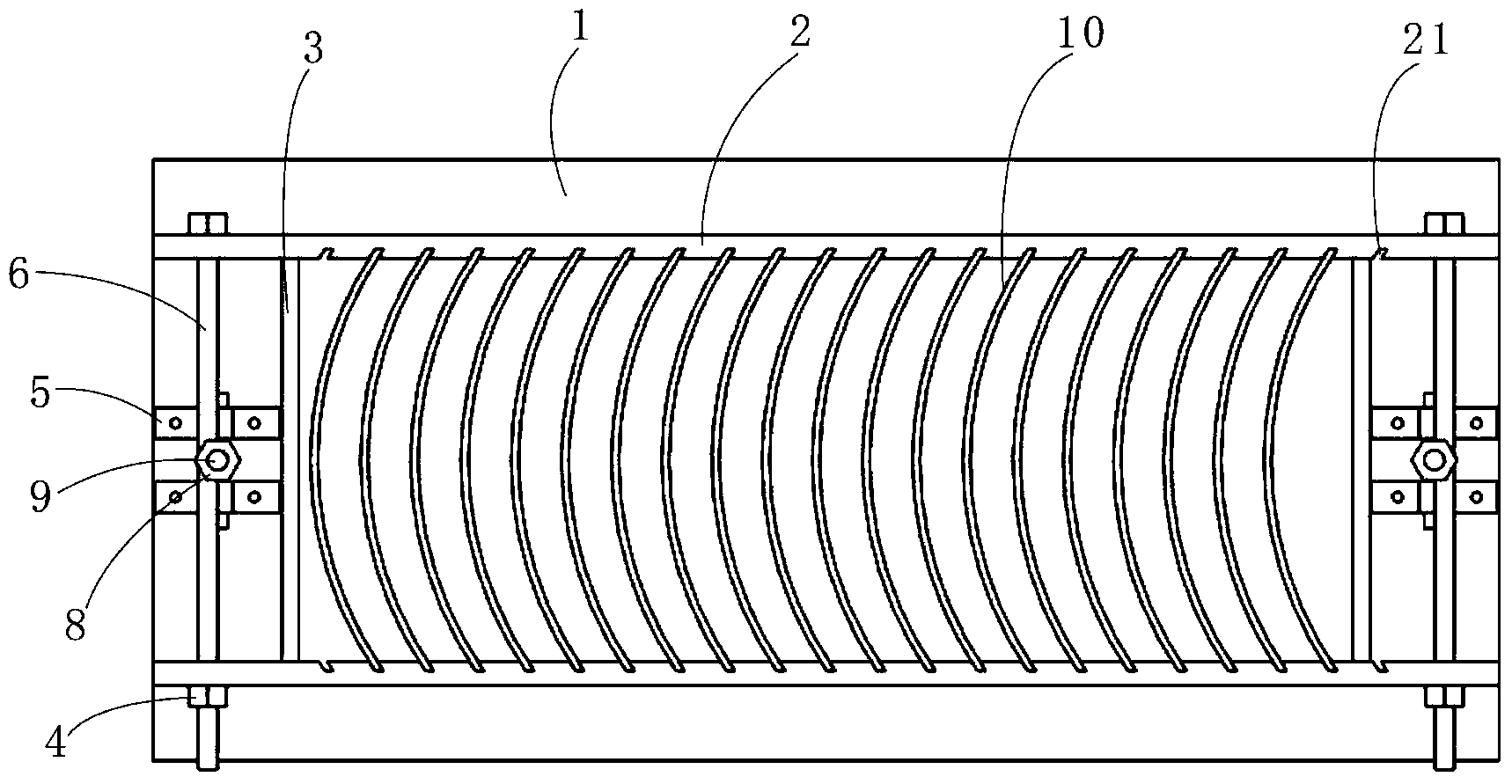

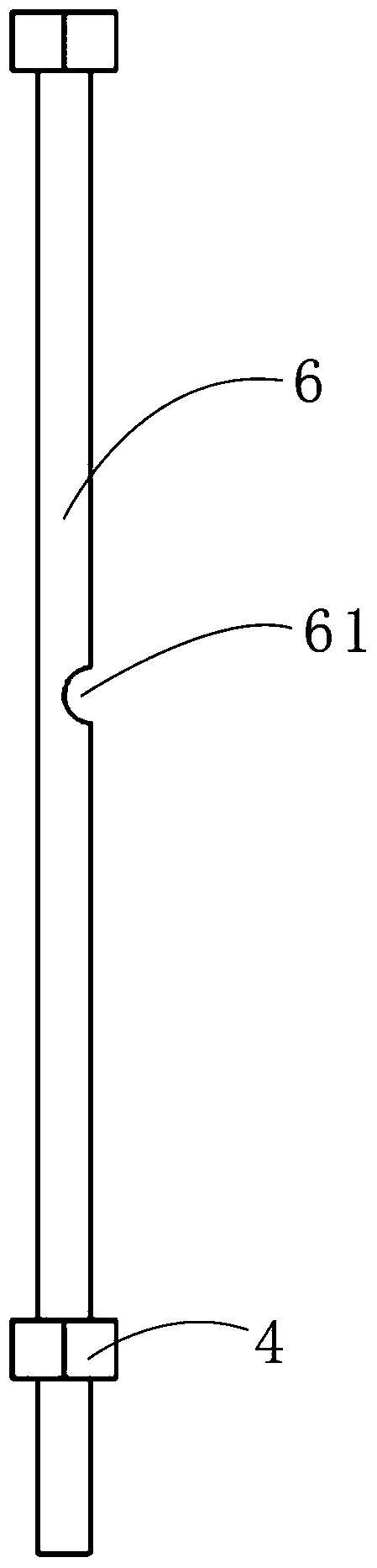

[0029] Example: such as Image 6 As shown, two limit screw rods 6 are used. In order to match the two limit screw rods 6, two upper and lower Ω-shaped card slots 7 are opened on the end of the side plate 2. At the same time, the same locking screw rod 9 is sleeved There are two lock nuts 8 . When in use, first place the two side plates 2 on the bottom plate 1, then insert the two limit screws 6 into the slots 7 on the end faces of the side plates 2, and gradually tighten the limit nuts 4 so that the side plates 2 gradually move closer together , until the distance between the two side plates 2 is 2-5mm greater than the length of the partition 10, stop tightening the limit nut 4, insert the baffle 3 between the two ends of the side plate 2, and then insert the partition 10 respectively Insert it into the clapboard clamping position 21 on the inner wall of the side plate 2. After the clapboard 10 is completely installed, continue to tighten the limit nut 4 until the baffle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com