Single-silver and low-emissivity coated glass with low shading coefficient

A low-emissivity coating, shading coefficient technology, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems that cannot meet the design requirements, general products do not have suitable structures, and high shading coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further elaborate the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

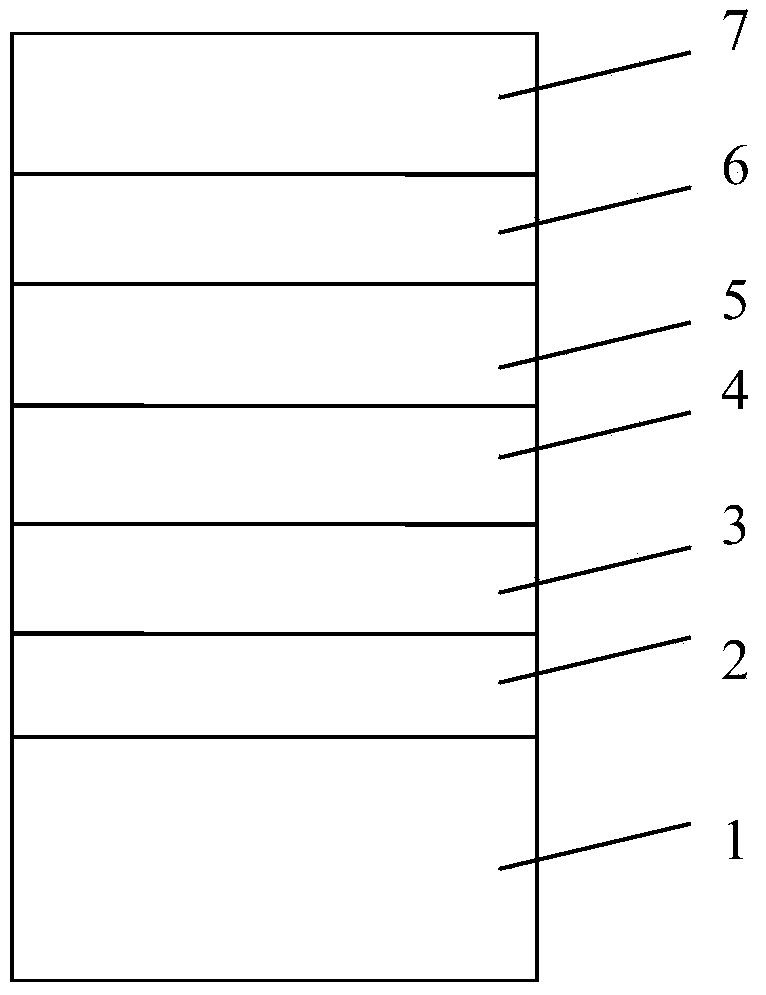

[0021] Such as figure 1 Shown, the single-silver low-emissivity coated glass of the low shading coefficient of the present invention has a glass substrate 1, and on the surface of the glass substrate 1, the first tin oxide film layer 2, the second tin oxide film layer 3, The chromium film layer 4, the silver film layer 5, the nickel-chromium film layer 6 and the silicon nitride film layer 7 constitute a single-silver low-emissivity coated glass with a six-layer film structure.

[0022] In one embodiment, the present invention uses a magnetron sputtering coating machine to coat six layers of nanomaterial films on the surface of float glass i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com