Multilayer medium double silver layer low-radiation film and production technique thereof

A technology of multi-layer dielectric and low-emissivity film, applied in metal material coating technology, layered products, metal layered products, etc., can solve the problem that the transmittance and shading coefficient cannot be taken into account at the same time, and the selection coefficient can only reach 1.4, etc. problems, to achieve the effect of easy adjustment, high transmittance, and low shading coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

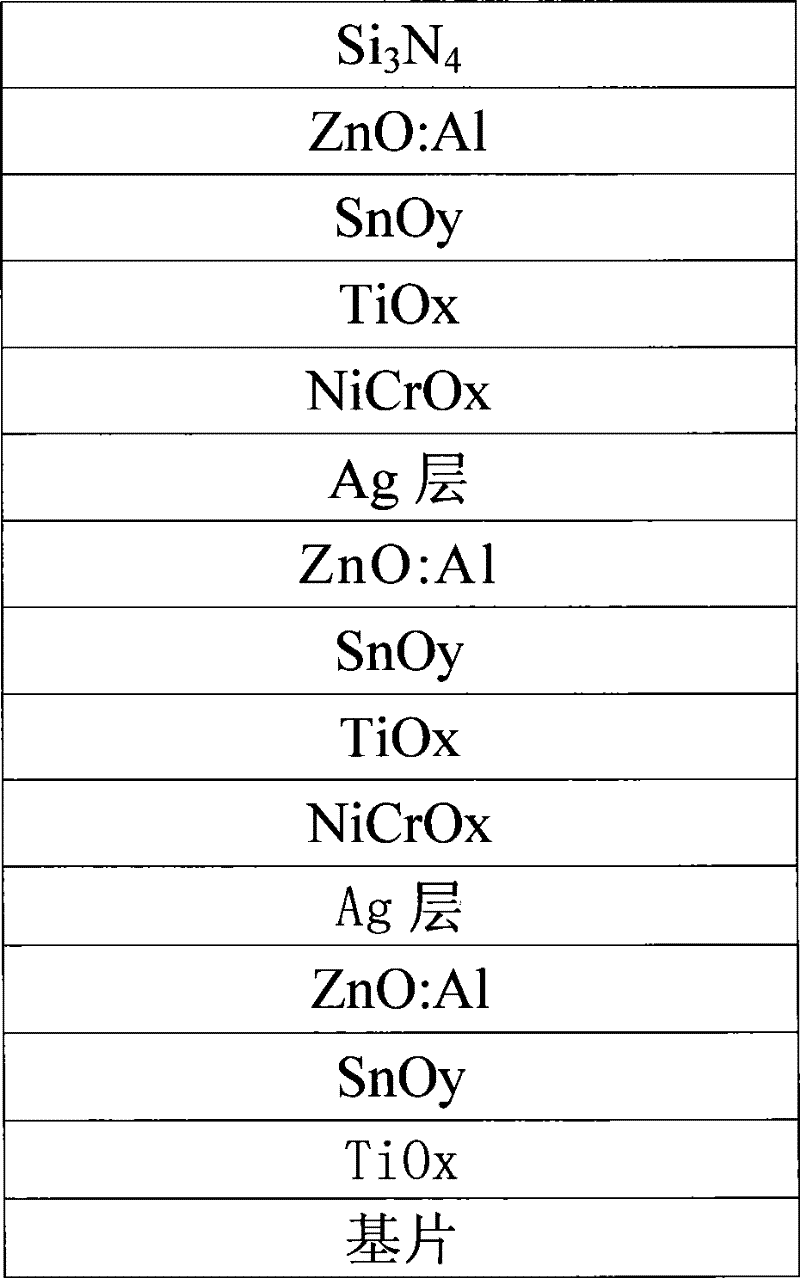

[0033] Embodiment 1, the multilayer dielectric film layer of the present invention adopts: TiOx / SnOy / ZnO:Al, the film layer of barrier layer adopts: NiCrOx, the film structure that constitutes the present invention is: glass / TiOx / SnOy / ZnO:Al / Ag / NiCrOx / TiOx / SnOy / ZnO:Al / Ag / NiCrOx / TiOx / SnOy / ZnO:Al / Si 3 N 4 . The production process of this application example is:

[0034] (1) substrate cleaning;

[0035] (2) Enter the vacuum sputtering area;

[0036] (3) Double rotating cathode, TiOx ceramic target material, TiOx film deposited by intermediate frequency reactive magnetron sputtering, film thickness 10-15nm;

[0037] (4) Double rotating cathodes, Sn metal target, medium frequency reactive magnetron sputtering deposition of SnOy film, film thickness 10-15nm;

[0038] (5) Double rotating cathode, ZnO:Al ceramic target material (Al content 2wt%), intermediate frequency reactive magnetron sputtering deposition ZnO:Al film layer, film thickness 10-15nm;

[0039] (6) Rotating cath...

Embodiment 2

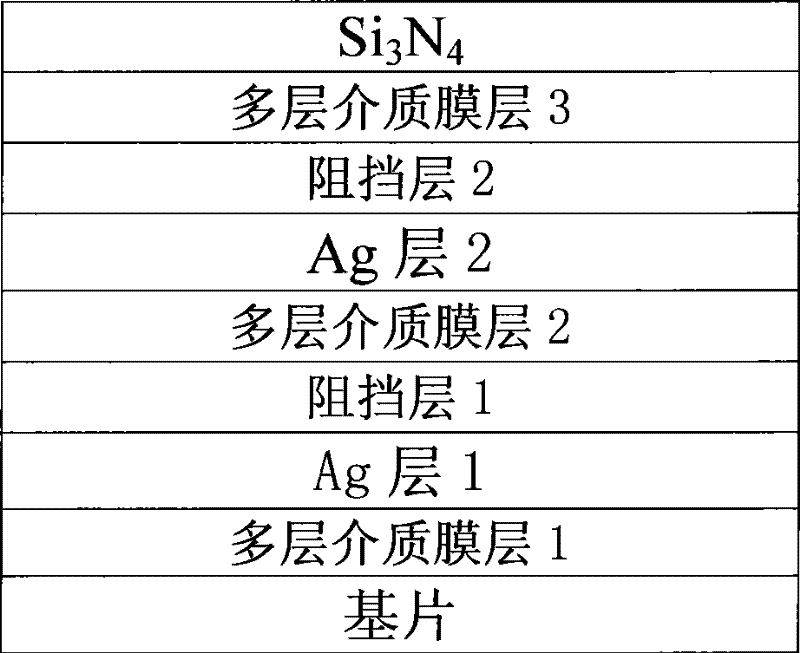

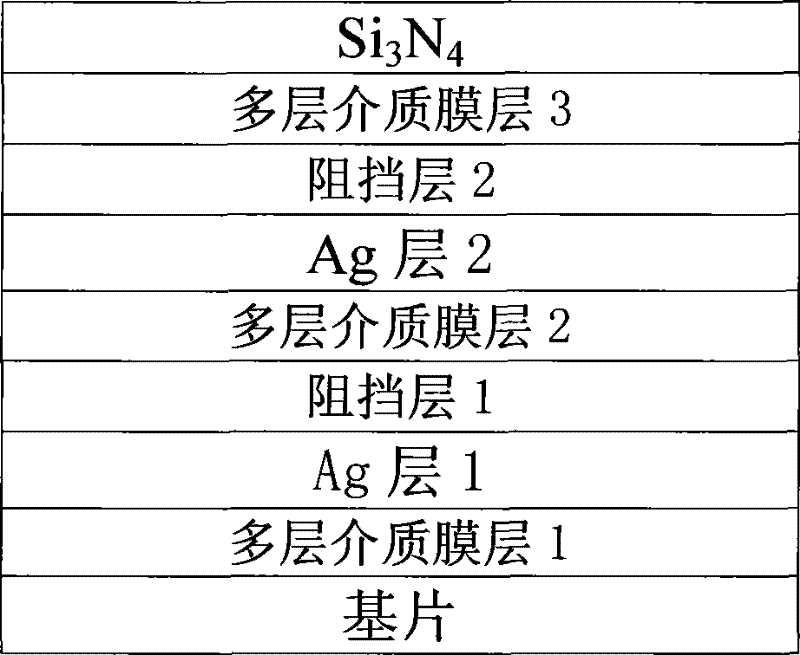

[0051] Embodiment 2, the composition of the multilayer dielectric film layer 1, 2 or 3 of the present invention can also be: SnOy / Si 3 N 4 / SnOy, ZnOx / SnOy / ZnOx, TiOx / SnOy / TiOx, or NbOy / Si 3 N 4 / NbOy, etc., the multilayer dielectric film layers 1, 2 and 3 can be the same any one of the above-mentioned film structures, or can be different any two or three of the above-mentioned film structures. The barrier layer 1 or 2 can be made of: NiCr, Nb, Ti, NiCrOx, or NbOx. The film layer of the barrier layer 1 or 2 can be the same any one of the above-mentioned film structures, or can be different of any two of the above-mentioned film structures. The material used for the substrate may include glass, plastic and other soft substrates and other materials available for film formation. refer to figure 1 with figure 2 , all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com