Method and device for preparing light-induced dimming glass through float double-alloy groove

A technology of dimming glass and double alloy, which is applied in the field of preparation of photosensitive dimming glass, can solve problems such as difficult temperature and time, increased equipment cost, and fast cooling rate, so as to reduce heating requirements, reduce residence time, and save use The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

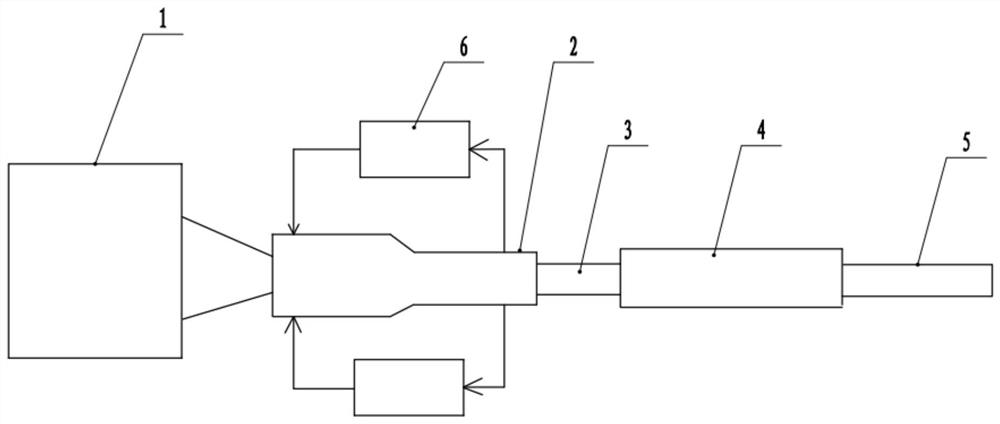

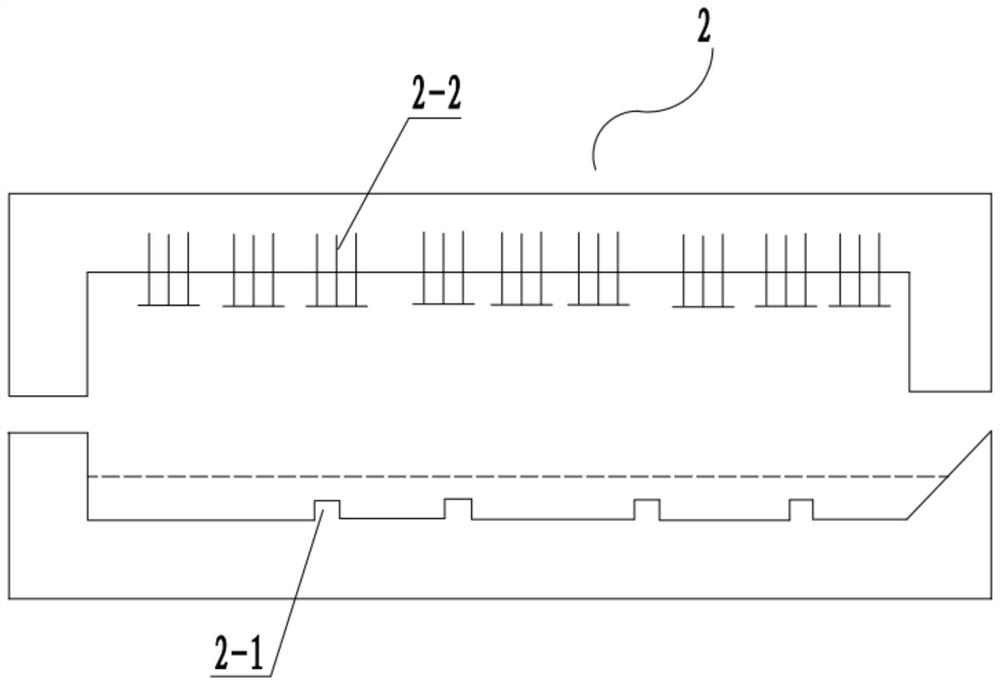

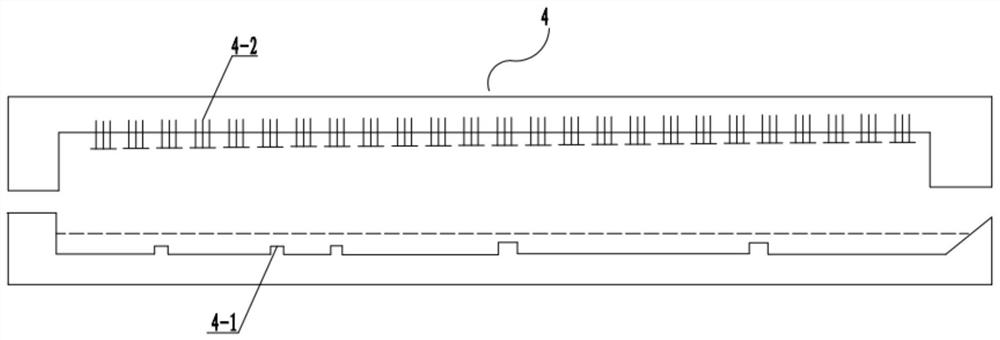

Method used

Image

Examples

Embodiment 1

[0038] The selected glass formula is shown in Table 1.

[0039] Table 1 Glass formulation

[0040] chemical composition weight percentage SiO 2

54.85 B 2 o 3

19.16 Al 2 o 3

6.08 Fe 2 o 3

0.02 Li 2 o

2.22 Na 2 o

3.62 K 2 o

6.84 CuO 0.02 Ag 0.25 Cl 0.6 Br 0.3 ZrO 2

2.91 TiO 2

1.73 CaO 0.80 MgO 0.60 total: 100.0

[0041] Preparation of batch materials, including: SiO 2 Introduced by quartz sand; Al 2 o 3 Introduced by aluminum hydroxide; B 2 o 3 Introduced by boric acid; CaO introduced by calcium carbonate; MgO introduced by magnesium carbonate; Na 2 O is introduced by soda ash; K 2 O is introduced by potassium carbonate; Li 2 O was introduced by lithium carbonate; Ag was introduced by silver nitrate; Cl was introduced by sodium chloride; Br was introduced by sodium bromide; CuO was introduced by copper oxide; ZrO 2 Use Zi...

Embodiment 2

[0053] The selected glass formula is shown in Table 5.

[0054] Table 5 Glass formulation

[0055] chemical composition weight percentage SiO 2

50.6 B 2 o 3

23.5 al 2 o 3

5.8 Fe 2 o 3

0.02 Li 2 o

3.5 Na 2 o

2.5 K 2 o

8.5 CuO 0.03 Ag 0.15 Cl 0.8 Br 0.3 ZrO 2

2.5 TiO 2

0.8 CaO 0.5 MgO 0.5 total: 100.0

[0056] Preparation of batch materials, including: SiO 2 Introduced by quartz sand; Al 2 o 3 Introduced by aluminum hydroxide; B 2 o 3 Introduced by boric acid; CaO introduced by calcium carbonate; MgO introduced by magnesium carbonate; Na 2 O is introduced by soda ash; K 2 O is introduced by potassium carbonate; Li 2 O was introduced by lithium carbonate; Ag was introduced by silver nitrate; Cl was introduced by sodium chloride; Br was introduced by sodium bromide; CuO was introduced by copper oxide; ZrO 2 Use Zirconium Di...

Embodiment 3

[0068] The selected glass formula is shown in Table 9 below.

[0069] Table 9 Glass formulation

[0070] chemical composition weight percentage SiO 2

62.8 B 2 o 3

14.6 Al 2 o 3

5.5 Fe 2 o 3

0.02 Li 2 o

2.6 Na 2 o

2.5 K 2 o

6.5 CuO 0.01 Ag 0.67 Cl 1.2 Br 0.1 ZrO 2

2.0 TiO 2

0.5 CaO 0.5 MgO 0.5 total: 100.0

[0071] Preparation of batch materials, including: SiO 2 Introduced by quartz sand; Al 2 o 3 Introduced by aluminum hydroxide; B 2 o 3 Introduced by boric acid; CaO introduced by calcium carbonate; MgO introduced by magnesium carbonate; Na 2 O is introduced by soda ash; K 2 O is introduced by potassium carbonate; Li 2 O was introduced by lithium carbonate; Ag was introduced by silver nitrate; Cl was introduced by sodium chloride; Br was introduced by sodium bromide; CuO was introduced by copper oxide; ZrO 2 Use Zircon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com