Temperable Low-E energy-saving glass

A low-e, glass technology, applied in the direction of coating, etc., can solve the problems of insufficient strength of mechanical properties, impact on product delivery time, insufficient mechanical properties, etc., to achieve excellent overall surface texture and meet high quality and low radiation The effect of blocking and strengthening the internal bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Toughened Low-E glass, on the original glass, sequentially plated 7.2nm silicon nitride layer, 8.1nm titanium oxide layer, 2.9nm nickel-chromium layer, 9.6nm silver layer, 2.5nm nickel-chromium layer, 11.8nm zinc oxide layer, 35nm silicon nitride layer and 5nm graphite layer. The above coating layer structures are arranged in sequence.

Embodiment 2-6

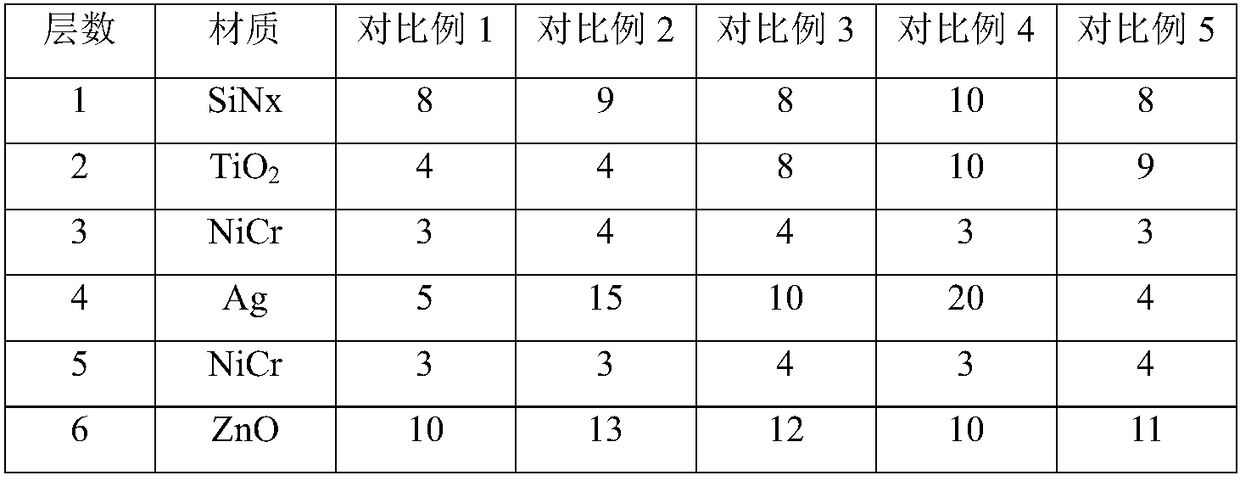

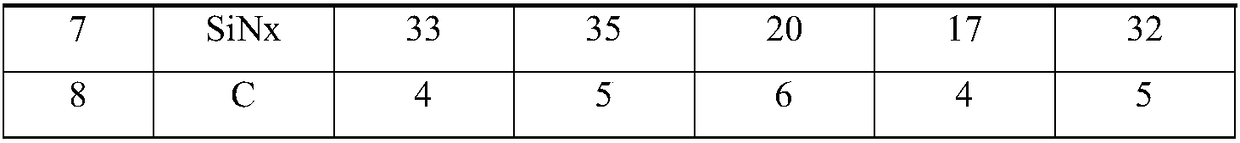

[0050] Temperable Low-E glass, using vacuum magnetron sputtering technology to sequentially coat silicon nitride layer, titanium oxide, nickel-chromium layer, silver layer, nickel-chromium layer, zinc oxide layer, silicon nitride layer on high-quality float glass substrate layer and graphite layer, the thickness control of each layer is shown in Table 1 below.

[0051] Table 1 Thickness control of temperable Low-E glass film

[0052] layers

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com