A Large Area Vacuum Gripper System

A large-area, vacuum technology, applied in the direction of manufacturing tools, conveyor objects, conveyors, etc., can solve the problems of inability to absorb items or workpieces, inability to absorb items forcefully, low work efficiency, etc., to achieve a wide range of use, structure Simple, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Referring to the drawings showing embodiments of the present invention, the present invention will be described in more detail below. However, the present invention can be implemented in many different forms and should not be construed as being limited by the embodiments presented herein. On the contrary, these embodiments are proposed to achieve a full and complete disclosure, and to enable those skilled in the art to fully understand the scope of the present invention. In these drawings, the sizes and relative sizes of layers and regions may be exaggerated for clarity.

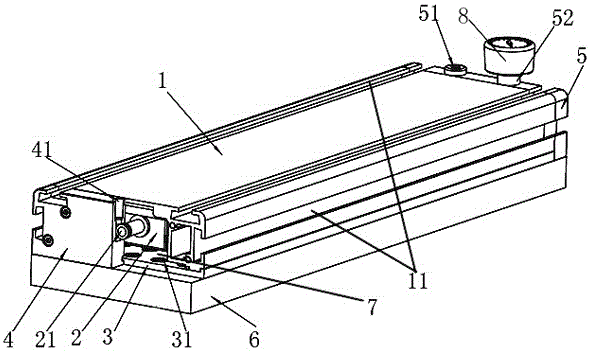

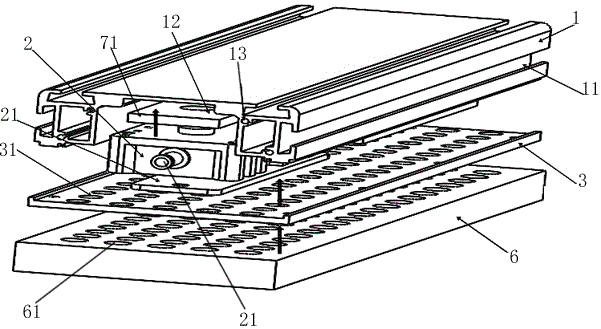

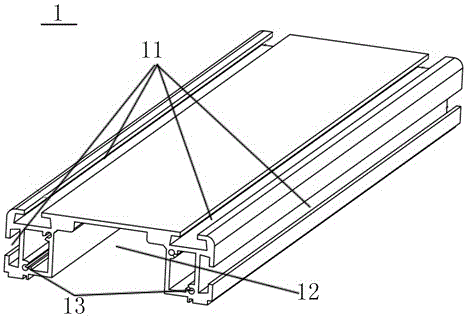

[0055] reference Figure 1-5 , The present invention provides a large-area vacuum suction system, which is generally installed on a robotic arm and sucks objects under the traction of the robotic arm. The large-area vacuum suction system mainly includes an extruded profile with a long groove 1, a flat suction plate 3 with a number of first through holes 31, and a vacuum generator 2. The vacuum generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com