Double-sleeper tamping device

A technology of external support and beams, applied in the direction of roads, tracks, ballast layers, etc., can solve the problems that tamping operations cannot be applied at the same time, and achieve the effects of being conducive to on-site maintenance, sufficient strokes, and long welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

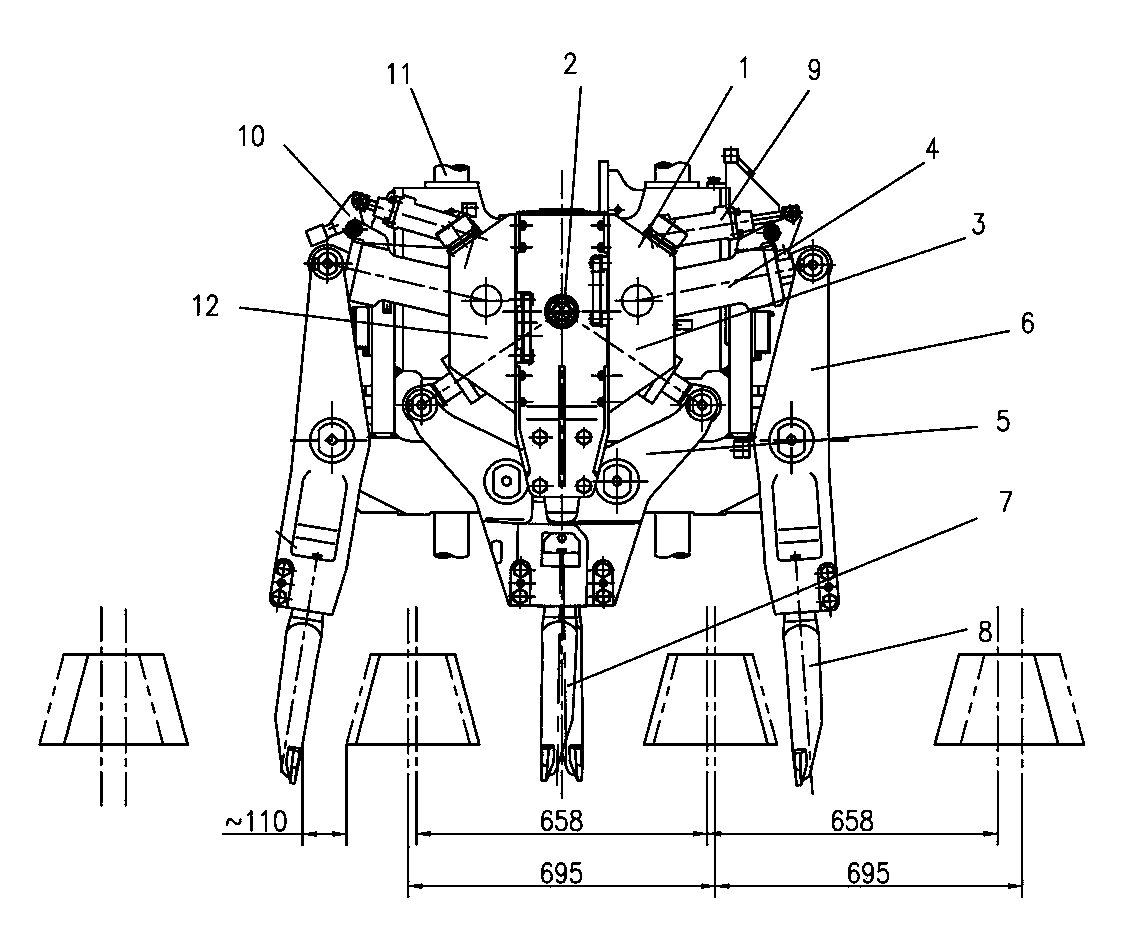

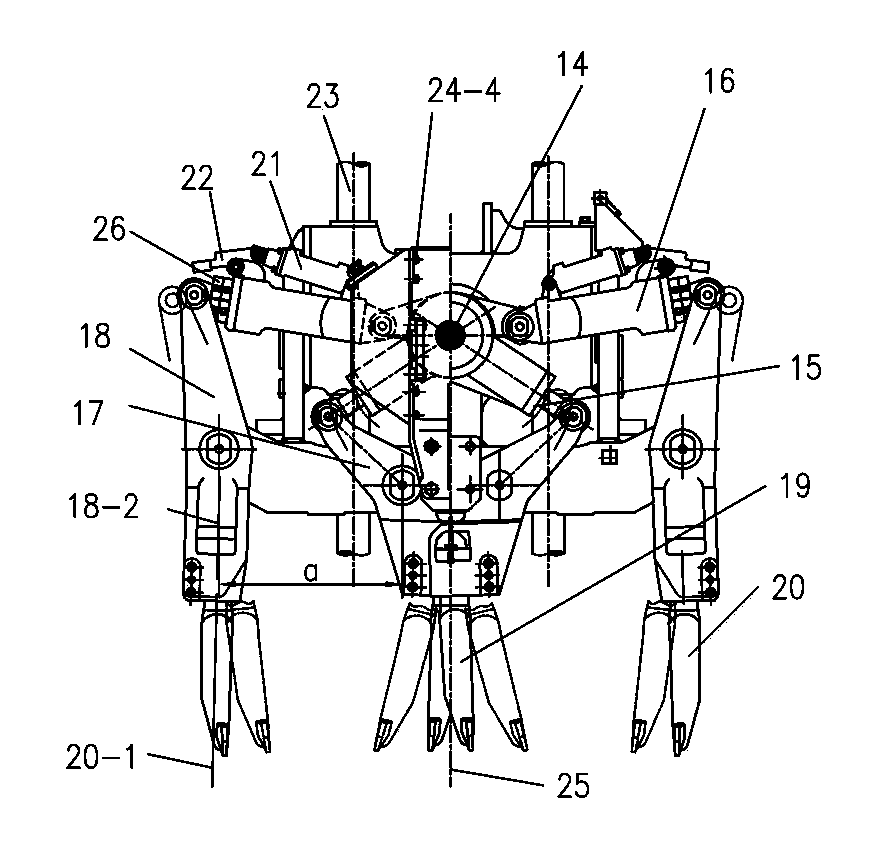

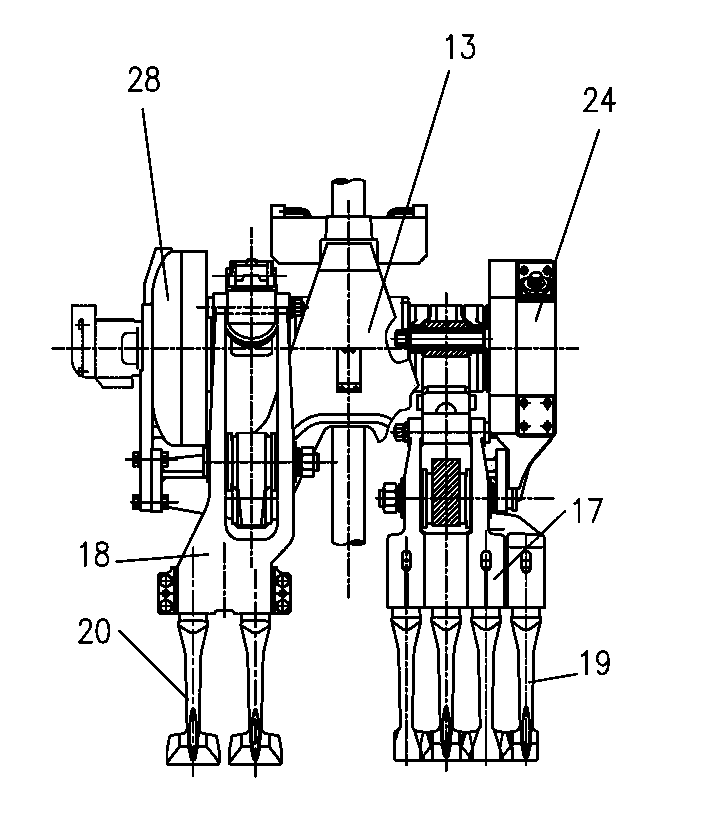

[0055] Such as figure 1 As shown, the DCL-32 tamping device of the prior art includes a box body 1, a vibrating shaft 2, an inner clamping oil cylinder 3, an outer clamping oil cylinder 4, an inner pick arm 5, an outer pick arm 6, an inner stamping pick 7, an outer Tamper pick 8, cylinder 9, block 10, guide post 11, supporting arm and oil tank 12. When the hydraulic motor drives the vibrating shaft 2 to rotate, its eccentric part produces eccentric movement, which is transmitted to the inner tamper 7 and outer tamper 8 through the inner clamping cylinder 3, outer clamping cylinder 4, inner pick arm 5, outer pick arm 6 , so that the pick palms of the inner pounding pick 7 and the outer pounding pick 8 are forced to vibrate slightly. The clamping force is generated by the action of the hydraulic system on the inner clamping cylinder 3 and the outer clamping cylinder 4, and the clamping force and movement pass through the piston rods of the inner clamping cylinder 3 and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com