Industrial steel tube bindle composite structure building system

A technology of combined structure and steel tube bundles, applied in the direction of buildings, structural elements, building components, etc., can solve the problems of poor economic performance, large amount of steel, complicated production, etc., to achieve simple construction, less waste, and high degree of industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

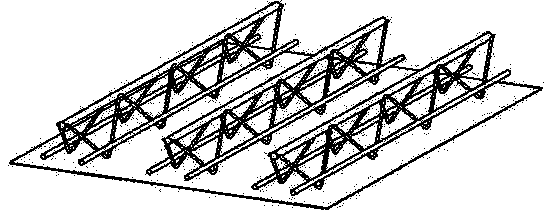

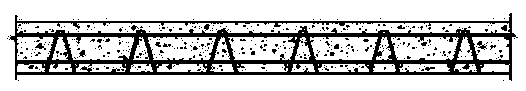

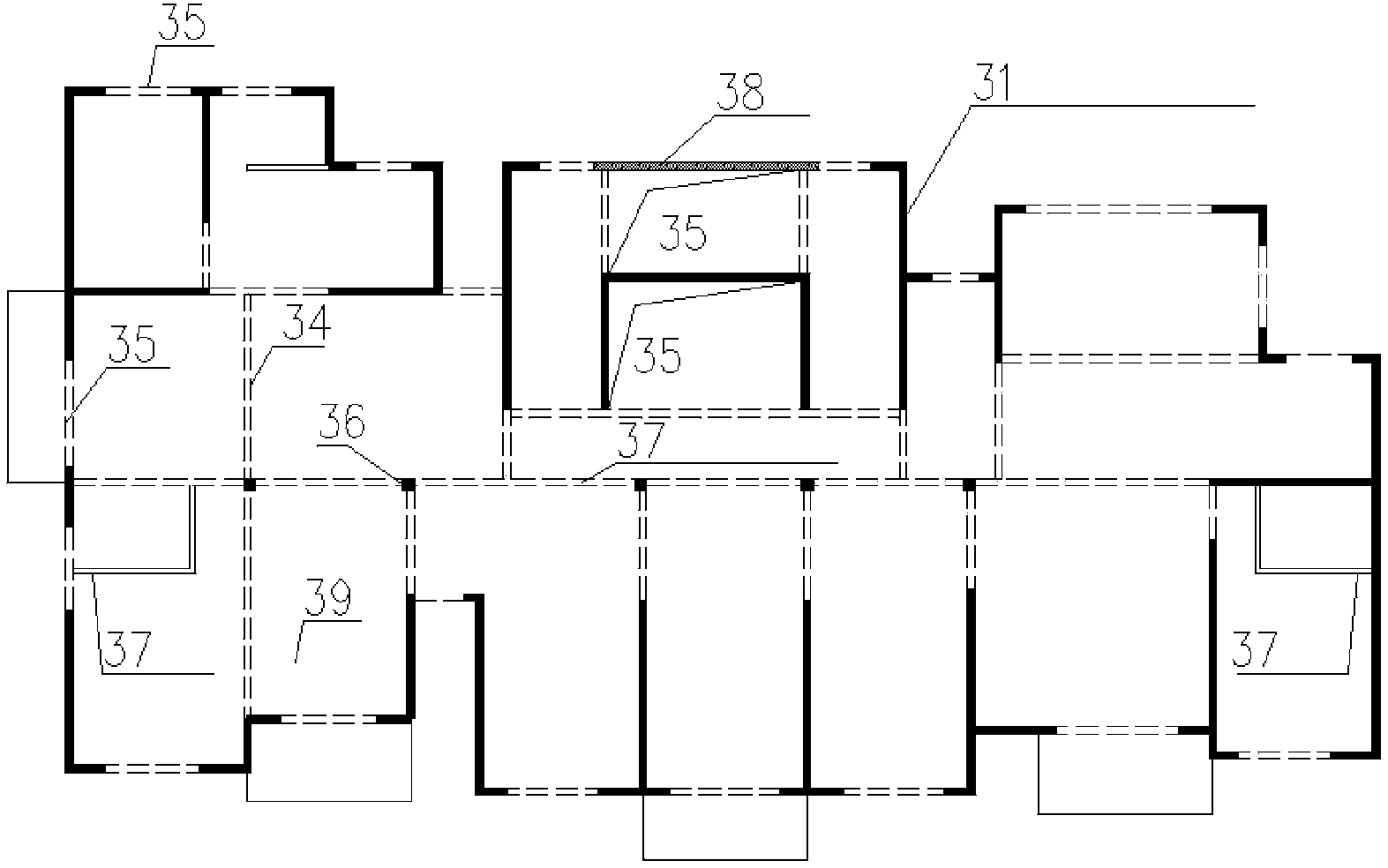

[0063] refer to Figure 1 to Figure 13 , an industrial steel pipe bundle composite structure building system, which is composed of a structural system, a floor panel system 39 and inner and outer walls 37, 38; the structural system can be a steel pipe bundle composite structure system or a frame-steel bundle composite structure system; the roof panel system can be steel truss floor slab, fabricated steel truss slab, concrete laminated slab or cast-in-place concrete slab; the inner wall 37 can be CCA board grouting wall, lightweight Composite wall or lightweight masonry; the external wall 38 can be a CCA board grouting wall, an integral external wall composed of a CCA board grouting wall and thermal insulation materials, or a composite composition of lightweight composite slat walls and thermal insulation materials The monolithic external wall or lightweight masonry;

[0064] The steel pipe bundle composite structural system is formed by connecting steel pipe bundle composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com