Electromagnetic Energy Feed Shock Absorber for Mine Vehicles

A technology of shock absorber and hydraulic shock absorber, which is applied in the direction of liquid shock absorber, vehicle parts, gear vibration/noise attenuation, etc., can solve the problems of generator damage, improve conversion efficiency, solve serious engine loss, enhance The effect of rotational continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

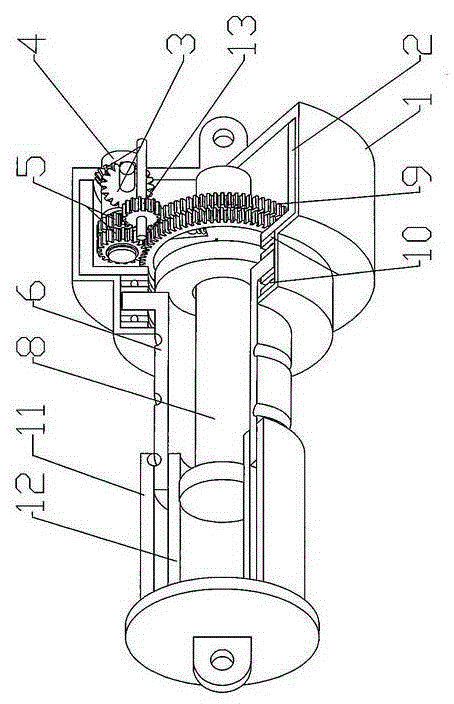

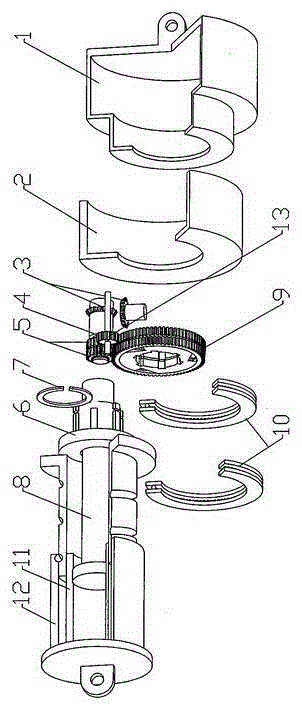

[0013] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention is improved on the basis of the traditional double-tube oil-gas shock absorber. The main transmission shaft 6 with the screw thread pair is arranged on the outside of the hydraulic shock absorber cylinder 12, and the main transmission shaft The outer side of 6 is provided with the ball screw shell 11 that cooperates with it.

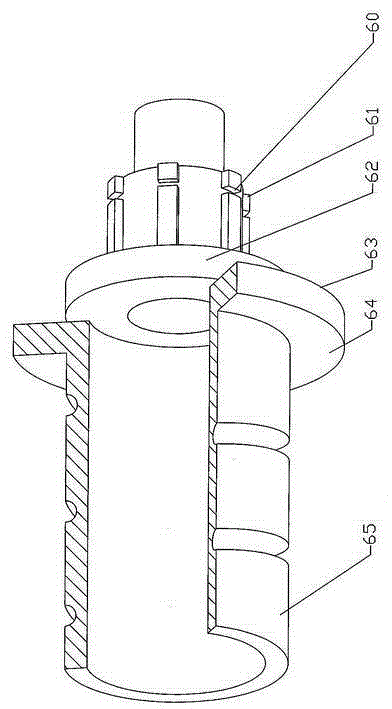

[0014] The main transmission shaft 6 is connected to the lower ear chamber 1 through a pair of bearing sets 10, and the part of the main transmission shaft 6 located in the lower ear chamber 1 is connected to the clutch gear set 9 through a spline 61, wherein the forward clutch gear 90 is directly connected to the The output gear set 5 is meshed, the reverse clutch gear 92 is connected with the output gear set 5 through the reversing idler gear 13, the output gear set 5 is connected with the bevel gear shaft 4 through the spline; the beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com