Device and method for rapid plugging of oil and gas pipelines

A technology for oil and gas transportation and pipelines, which is applied in the field of auxiliary equipment for maintenance of oil and gas pipelines. It can solve the problems of inability to squeeze the sealant, troublesome operation, unreliable sealing of the rubber sealing ring, etc., and achieve the effect of reliable sealing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

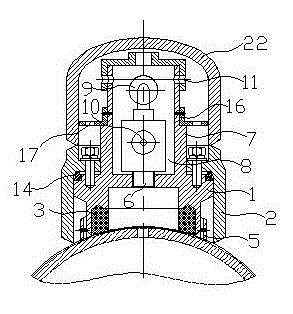

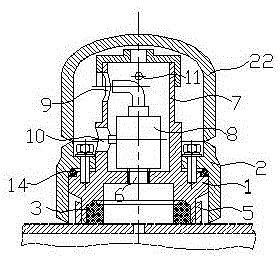

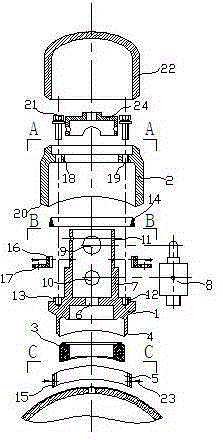

[0043] Figure 1~Figure 7 Among them, the rapid plugging device for oil and gas pipelines has a cylindrical inner steel cover 1 and an outer steel cover 2 that are set together.

[0044] The inner circumference of the inner steel cover is embedded with a cylindrical rubber sealing ring 3, the lower end of the rubber sealing ring and the inner steel cover is a saddle-shaped ring cover, and the edge of the saddle-shaped ring cover at the lower end of the inner steel cover has an outer chamfer 4, and the inner There is a clamping ring 5 connected by two saddle-shaped semicircular steel rings around the outer circle of the lower end of the steel cover, and there is a connecting socket 15 between the two saddle-shaped semicircular steel rings of the clamping ring. To the screw 23, the hood top of the inner steel cover has a drainage port 6 whose axis is on the same line as the axis of the inner steel cover, and there is an upper cylinder whose axis is on the same line as the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com