Measuring combination tool for prefabrication installation of pipeline

A technology of prefabricated installation and combined tools, which is applied in the direction of measuring devices, mechanical measuring devices, angle/taper measurement, etc., can solve the problems of large measurement accuracy error, cumbersome operation process, and discounted working time, so as to reduce the amount of rework, Ease of tool operation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

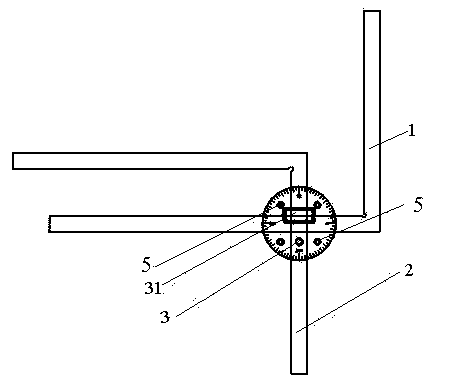

[0047] Such as Figure 1 to Figure 15 As shown, the combined measurement tool for prefabricated installation of the measuring pipeline of this patent includes a first ruler or square 1, a second ruler or square 2, an upper rotating body, and a lower rotating body.

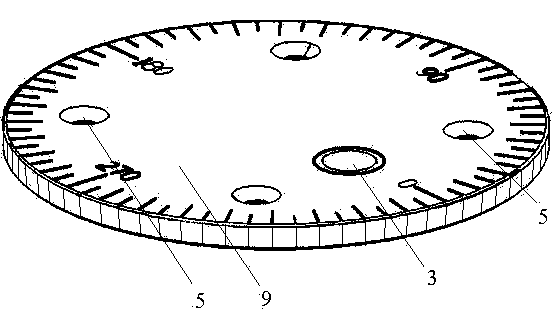

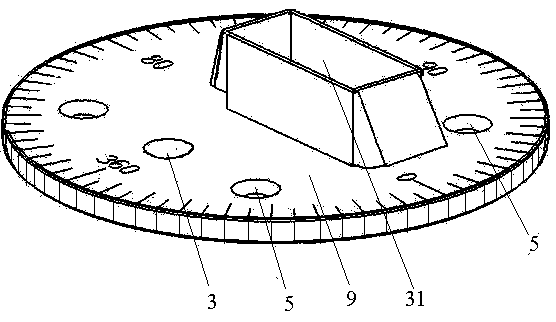

[0048] Wherein, the upper rotating body includes an upper gland, an upper rotating disc 10, a rotating table 6, and four upper fixing bolts; wherein, the upper gland is a circular metal block, and is provided with an upper positioning hole 3 and four upper fixing circular holes 5 ; The upper rotating disk 10 is a circular metal block, and the center position of the upper surface of the upper rotating disk 10 is provided with a first through chute 11, 4 upper fixing bolt holes, and a lower positioning hole 4 corresponding to the upper positioning hole 3; The positioning hole 3 and the lower positioning hole 4 are both bolt holes; the upper fixing bolt hole corresponds to the upper fixing round hole 5 of the upper gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com