Field test system for mechanical properties of existing glass curtain wall structural adhesive

A glass curtain wall, on-site detection technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., can solve the problem that the quality of existing curtain wall structural adhesives cannot be truly reflected, and the test methods are difficult to popularize and use. Destroy the glass panel of the curtain wall and other problems, and achieve the effect of saving test costs, easy to popularize and use, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

[0028] Refer below Figures 1 to 6 Examples of the present invention will be described.

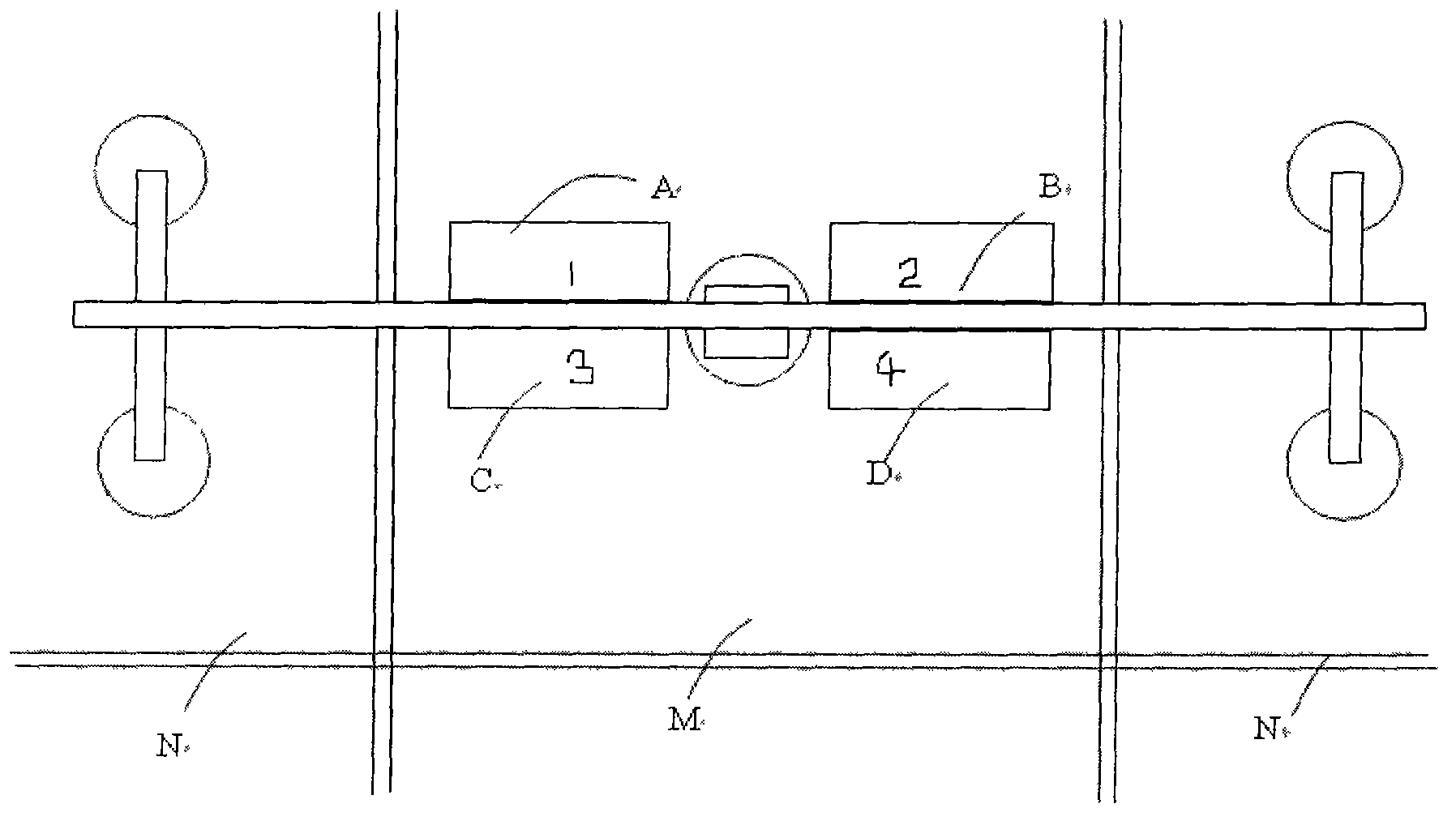

[0029] Please see attached figure 1 As shown, the glass curtain wall bonding performance detection system includes a drive control system 1, a power supply system 2, a fixed suction cup vacuum maintenance system 3, and a tension suction cup vacuum maintenance system 4; Supported in four boxes A-D.

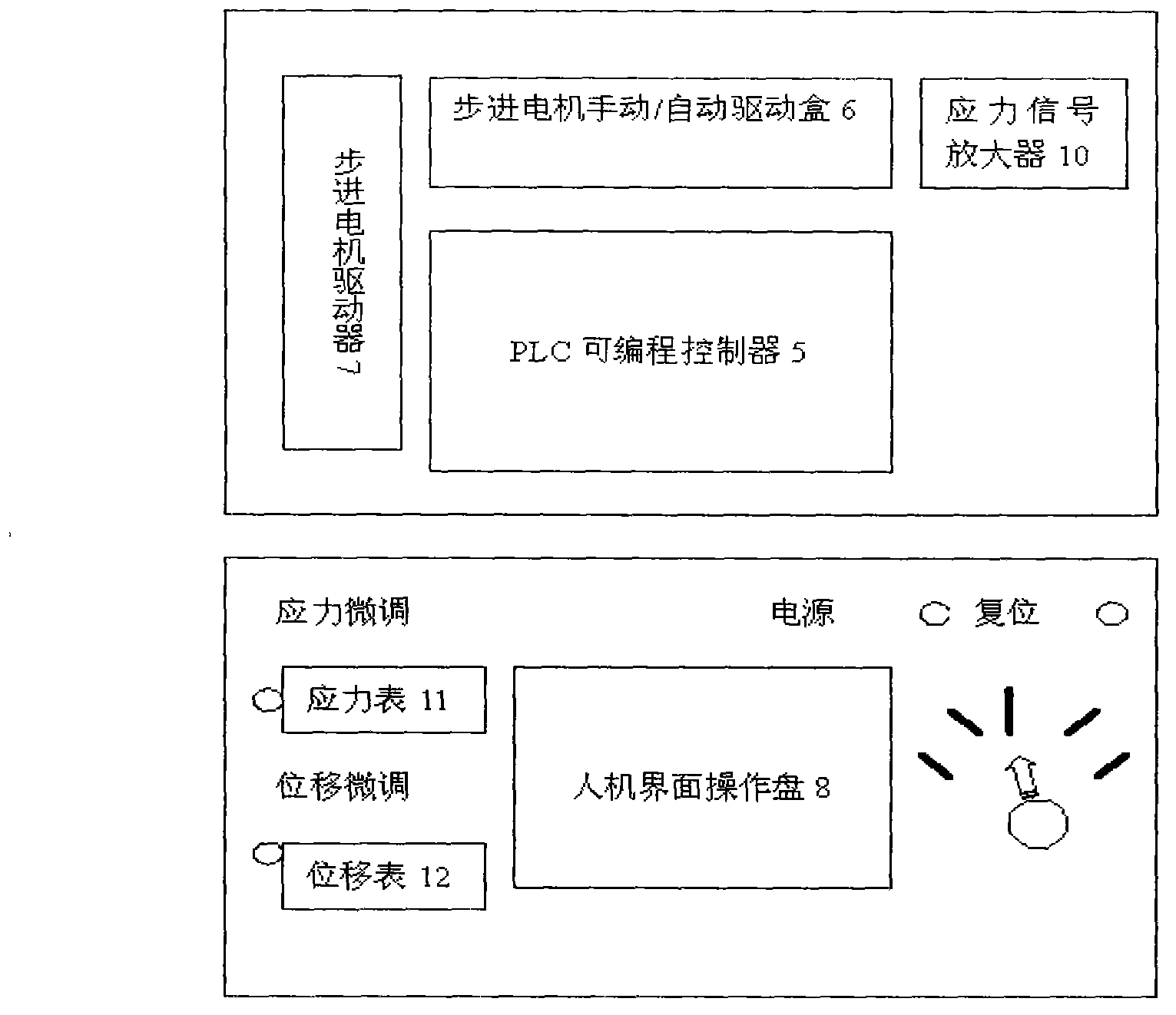

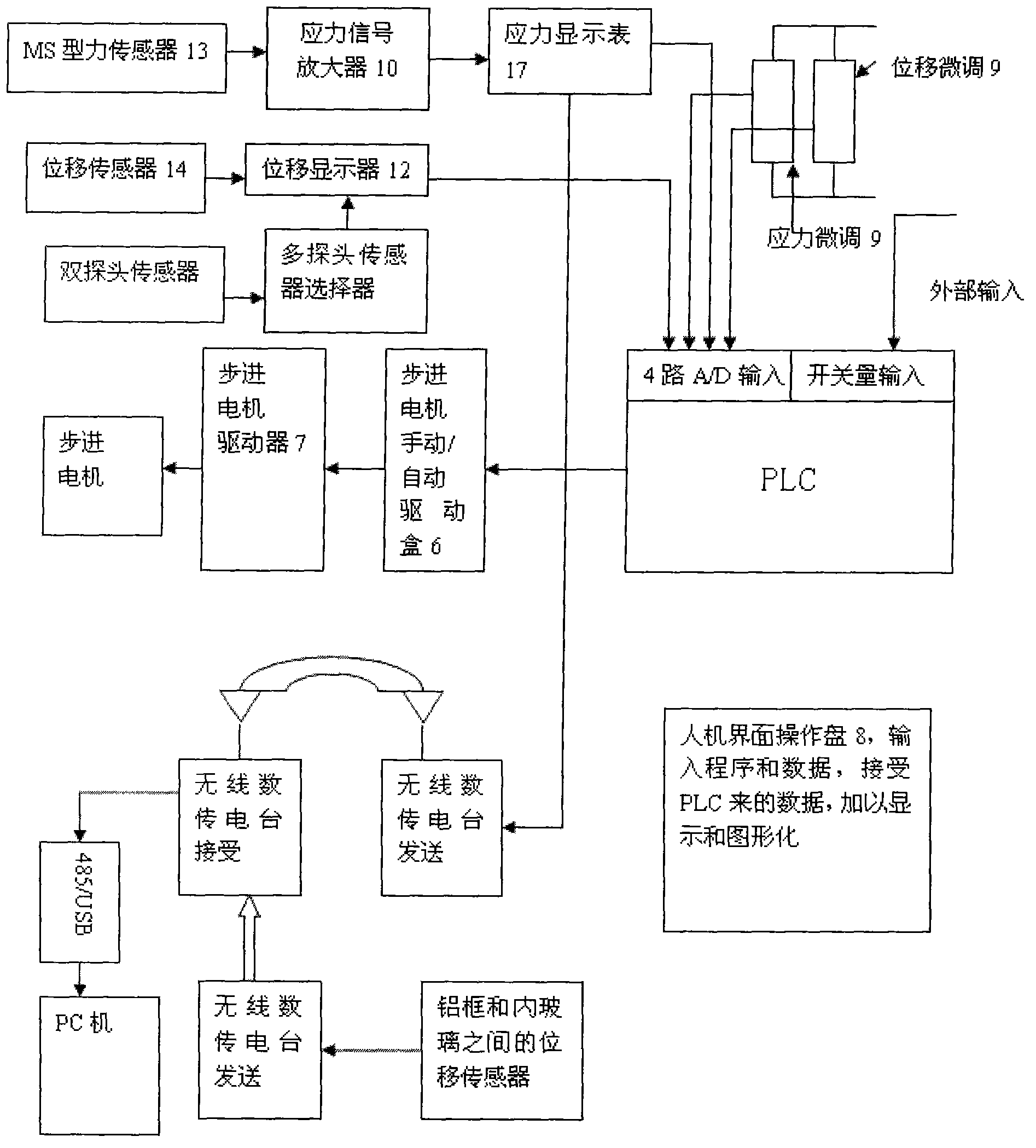

[0030] as attached figure 2 As shown, the drive control system 1 is accommodated in a box A, which includes a PLC programmable controller 5, a stepper motor manual / automatic drive box 6, a stepper motor driver 7, a man-machine interface operation panel 8, and stress / displacement fine-tuning Device 9, stress signal amplifier 10, stress display table 11, displacement display table 12, and buttons, switches, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com