Online solid waste incineration treatment analysis system

An analysis system and analyzer technology, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of inability to detect multiple gases at the same time, high cost, and ensure non-destructive measurement, reduce corrosion, and stable properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

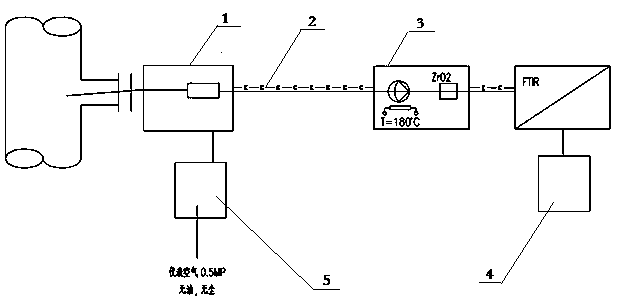

[0029] Example: The online analysis system for solid waste incineration treatment in this example is attached figure 1 As shown, it mainly includes heating sampling unit, flue gas high temperature conveying unit, high temperature box pretreatment unit, pressure sensor, calibration unit, analyzer purging unit and data processing unit.

[0030] In this embodiment, the flue gas flow process: the flue gas is heated and filtered in the sampling probe 1, kept warm through the heat tracing pipeline 2, and transported to the high temperature box 3 by the air pump (the high temperature box contains a flue gas filtering unit, a heating unit, a flue gas Control components), after passing through the zirconia sensor and FTIR analyzer measuring pool, it is discharged from the system.

[0031] The sampling system includes a sampling probe 1, a heating line 2, a blowback box 5, and the like. The ceramic filter element of the sampling probe 1 has a pore size of 2 microns, which can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com