LED supporting frame, manufacturing method of LED supporting frame and double-material belt LED supporting frame module

A technology of LED brackets and materials, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the emissivity of vulcanized products, and achieve the effects of improving product assembly efficiency, better performance, and preventing vulcanization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

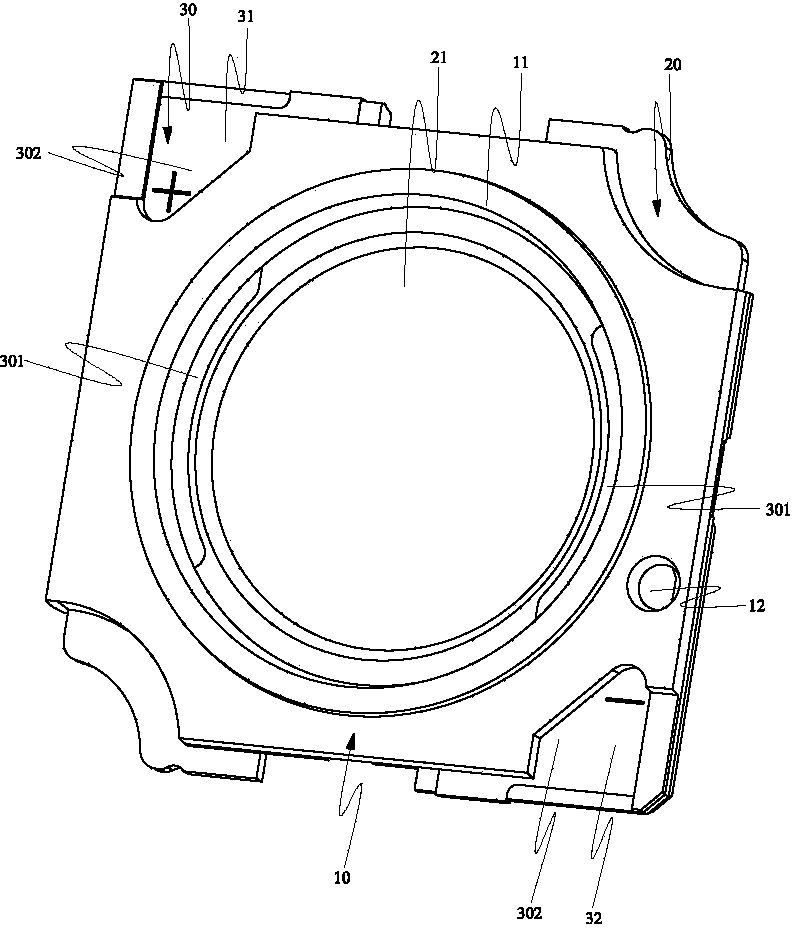

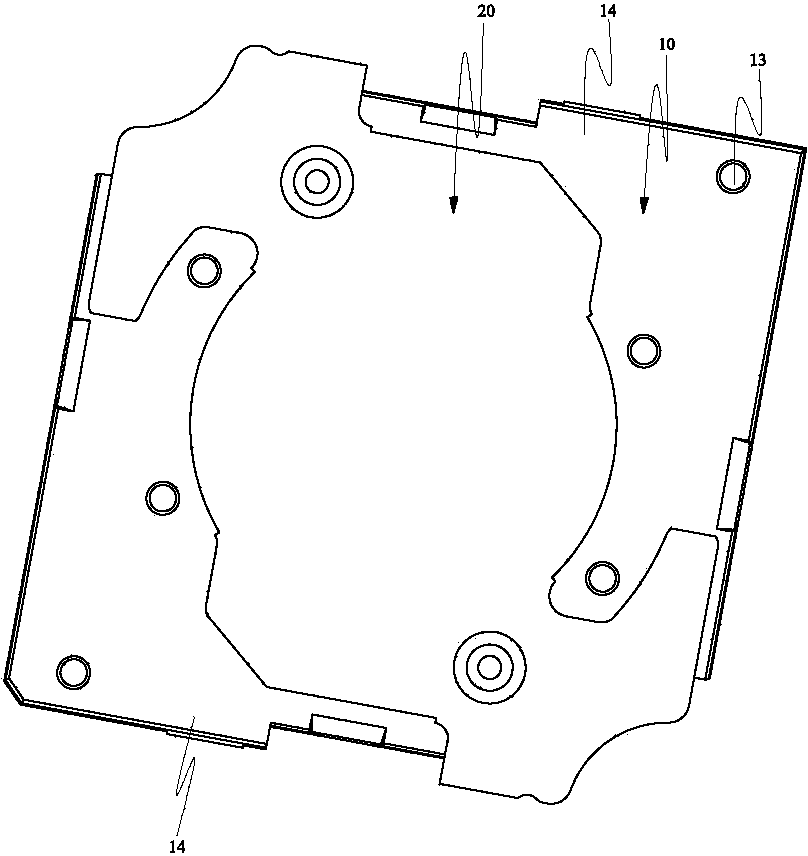

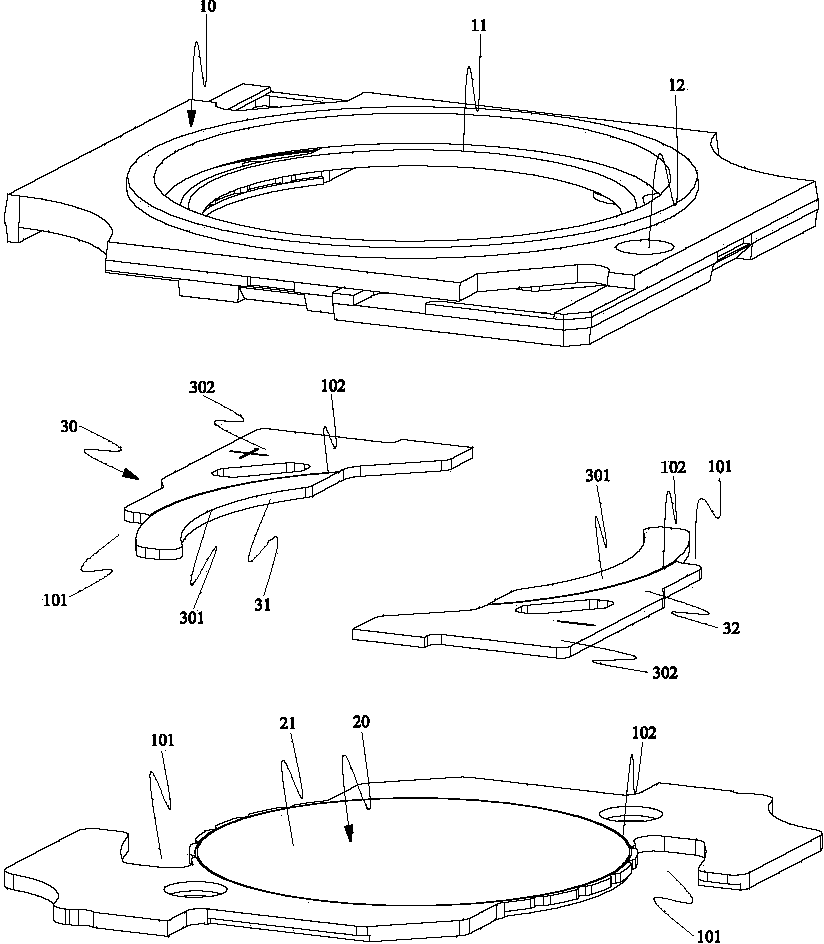

[0046] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the LED bracket in the preferred embodiment of the present invention, including a plastic seat 10 and an aluminum patch 20 and a copper guide pin 30 disposed on the plastic seat 10 .

[0047] The plastic seat 10 is provided with a packaging cavity 11, which is used to accommodate and package LED chips (not shown in the figure),

[0048] The aluminum patch 20 has a crystal-bonding portion 21, the surface of which is exposed in the package cavity 11, and the crystal-bonding portion 21 is used to accept LED chips, and the bottom surface of the aluminum patch 20 is exposed on the plastic seat 10. Bottom surface, in this embodiment, the aluminum patch 20 is made of mirror aluminum material, which can more effectively prevent the vulcanization problem in the die-bonding wire area, and at the same time improve the reflectivity of the product and enhance the product’s reliability. The brightness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com