Optical semiconductor, method for producing same, surface treatment agent for silver, and light-emitting device

A technology for optical semiconductor devices and light-emitting devices, which is applied in the field of silver surface treatment agents and light-emitting devices, and can solve the problems of black, chemical instability of silver and silver alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

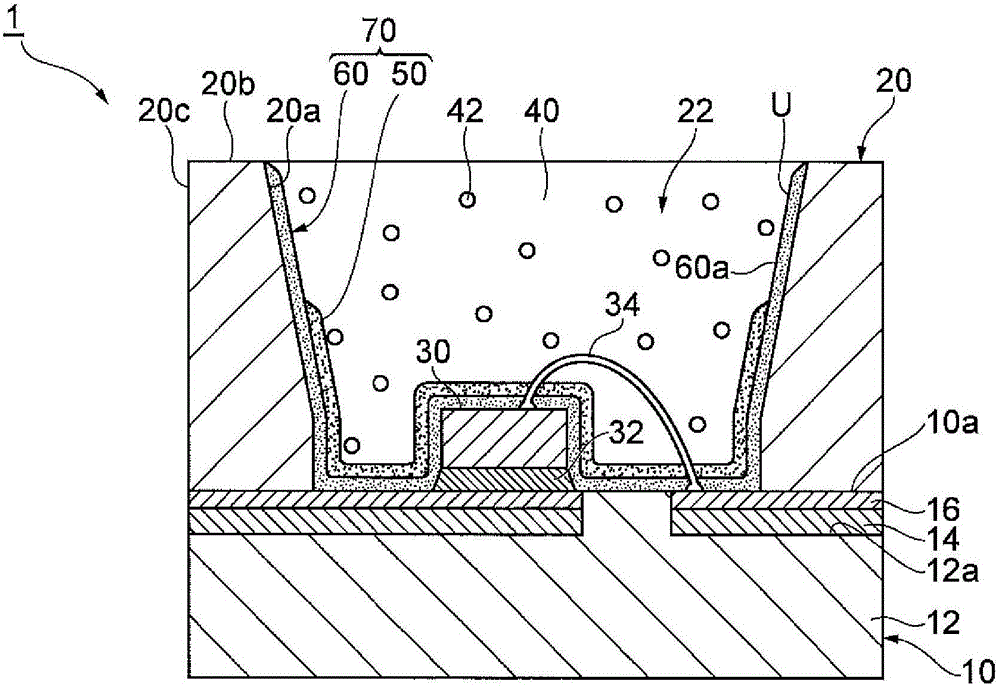

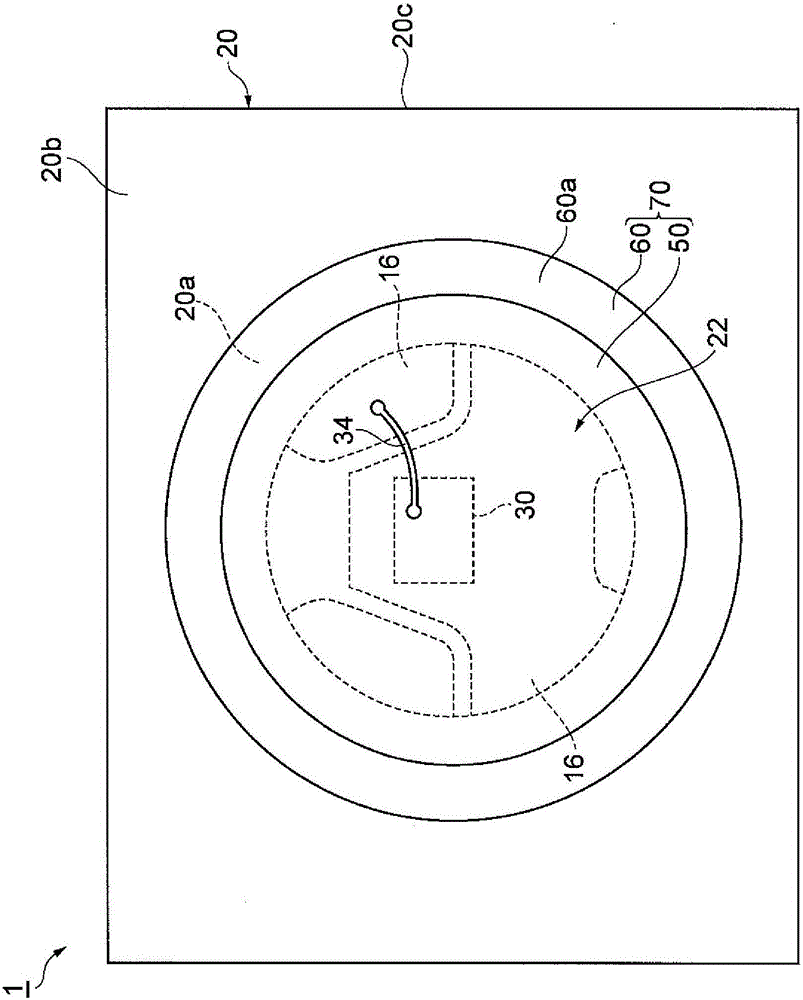

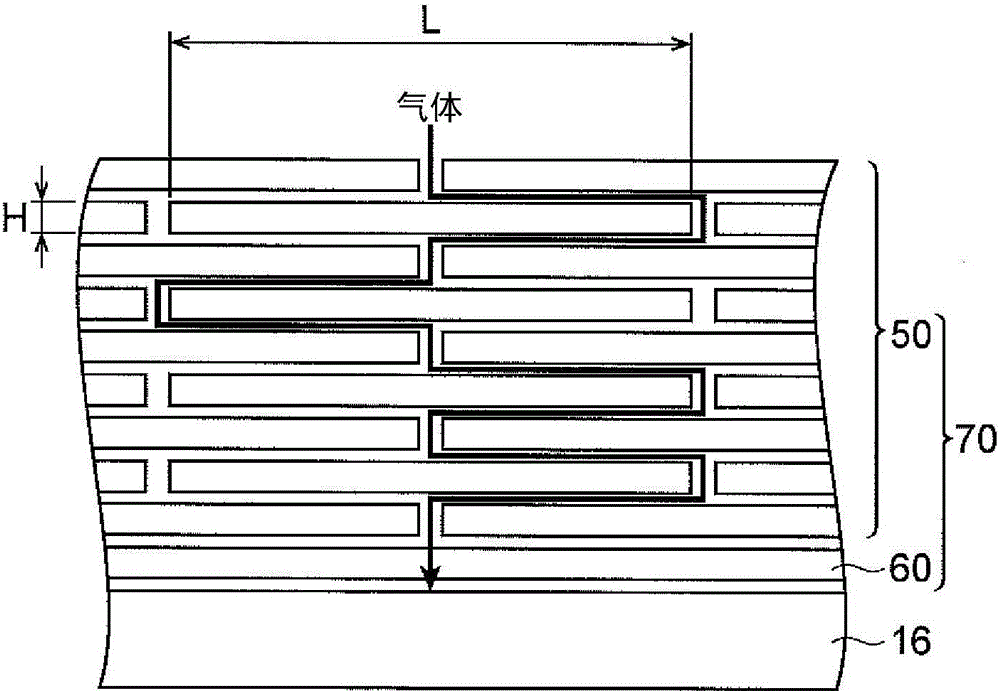

[0105] figure 1 It is a sectional view of the optical semiconductor device of the first embodiment. figure 2 for figure 1 A top view of the optical semiconductor device shown. Such as figure 1 and figure 2 As shown, the optical semiconductor device 1 of the embodiment is generally classified as "surface mount type". This optical semiconductor device 1 includes a substrate 10, a blue light-emitting diode 30 bonded to the surface of the substrate 10, a reflector 20 provided on the surface of the substrate 10 so as to surround the blue light-emitting diode 30, and a blue light-emitting diode 30 filled in the reflector 20. The transparent sealing part 40 which seals the light emitting diode 30, and the anti-silver sulfide film 70 which coats the silver-plated layer 16. in addition, figure 2 The illustration of the transparent sealing part 40 is omitted in .

[0106] In the substrate 10 , a copper-plated plate 14 is wired on the surface of an insulating base 12 , and a si...

no. 2 Embodiment approach

[0134] Next, a second embodiment will be described. The second embodiment is basically the same as the first embodiment, and only the formation position of the gas barrier layer is different from the first embodiment. Therefore, in the following description, only the points different from those of the first embodiment will be described, and the same description as that of the first embodiment will be omitted.

[0135] Image 6 It is a cross-sectional view of the optical semiconductor device of the second embodiment. Such as Image 6 As shown, the optical semiconductor device 2 of the second embodiment includes a silver sulfide preventing film 72 instead of the silver sulfide preventing film 70 of the first embodiment.

[0136] The silver sulfide prevention film 72 includes a gas barrier layer 52 and an undercoat layer 60 . The gas barrier layer 52 is basically the same as the gas barrier layer 50 , but differs from the gas barrier layer 50 in that the light reflection surf...

no. 3 Embodiment approach

[0140] Next, a third embodiment will be described. The third embodiment is basically the same as the first embodiment, and only the formation positions of the undercoat layer and the gas barrier layer are different from the first embodiment. Therefore, in the following description, only the points different from those of the first embodiment will be described, and the same description as that of the first embodiment will be omitted.

[0141] Figure 8 It is a cross-sectional view of the optical semiconductor device of the third embodiment. Such as Figure 8 As shown, the optical semiconductor device 3 of the third embodiment includes a silver sulfide preventing film 73 instead of the silver sulfide preventing film 70 of the first embodiment.

[0142] The silver sulfide preventing film 73 includes an undercoat layer 63 and a gas barrier layer 53 .

[0143]The undercoat layer 63 is basically the same as the undercoat layer 60, but differs from the undercoat layer 60 in that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com