Aged golden-flower dark green tea and processing technic thereof

A processing technology and black tea technology, which is applied in the field of aged tea Jinhua dark tea and its processing technology, can solve problems such as economic loss, achieve the effects of mellow and smooth taste, bright soup color, and increase bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Stir-fried green tea golden flower dark tea and processing technology thereof

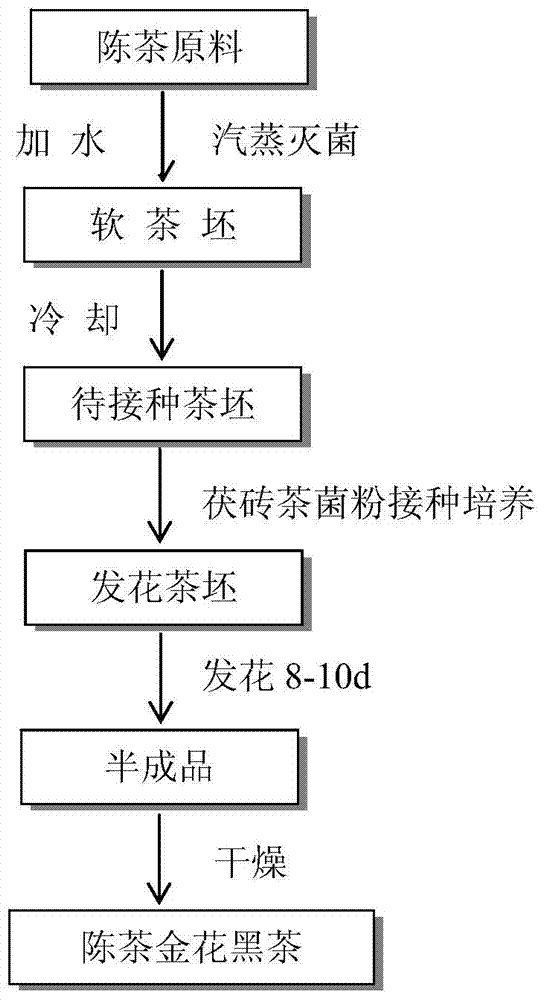

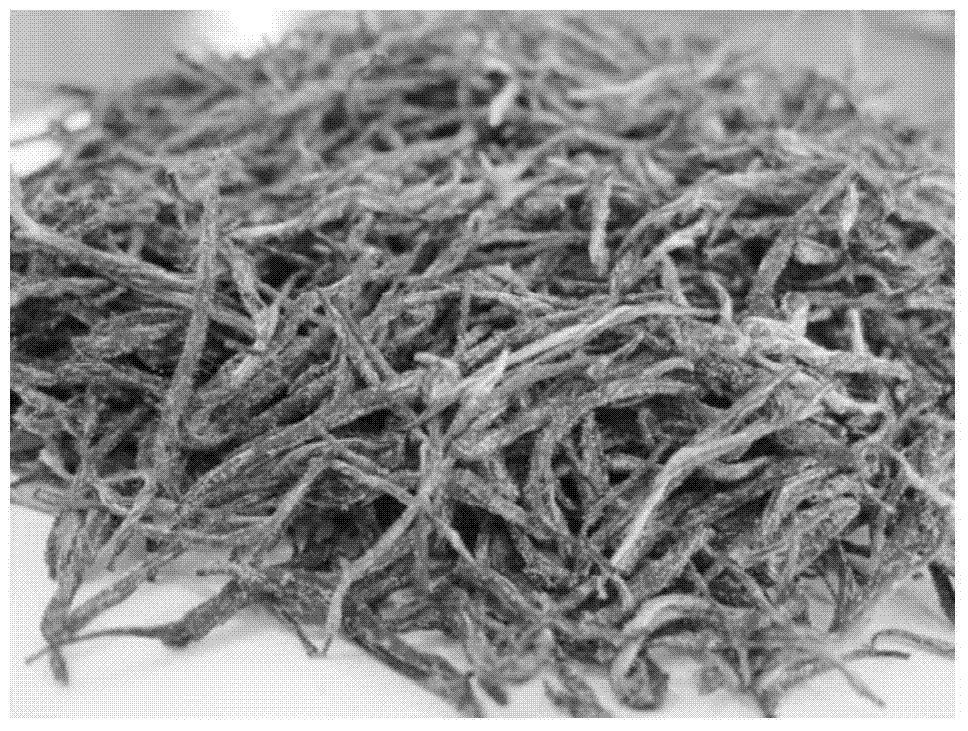

[0024] (1) Use aged roasted green tea as processing raw material, add 20% fresh water of processed aged tea quality, stir evenly, put it in a sterilizer to sterilize at 121°C for 10 minutes, and obtain the green tea base to be inoculated after cooling; (2) Put it in the market Fuzhuan brick tea is crushed, inoculated into the sterilized aged tea base according to the weight of 1% of the tea base, and carefully stirred evenly; (3) The inoculated tea leaves are placed in a relatively closed environment at 23-28°C for static cultivation for 8 -10d; (4) After the cultivation, the tea leaves were taken out and placed in an oven at 70°C to dry for 2 hours to obtain the finished product of aged tea fried green tea golden flower black tea ( figure 2 ).

Embodiment 2

[0025] Embodiment 2 old tea Longjing tea Jinhua dark tea and its processing technology

[0026] (1) Using aged Longjing tea as processing raw material, add 18% of the processed aged tea quality water and stir evenly, put it in a sterilizer to sterilize at 121°C for 10 minutes, and obtain the tea base to be inoculated after cooling; (2) Commercially available Pulverize Fuzhuan tea, inoculate 1% of the tea base into the sterilized old tea base, and stir carefully; (3) Place the inoculated tea leaves in a relatively closed environment at 23-28°C for static cultivation for 8- 10d; (4) After the cultivation, the tea leaves were taken out and placed in an oven at 70°C to dry for 2 hours to obtain the finished aged tea Longjing tea Jinhua dark tea ( image 3 ).

Embodiment 3

[0027] Embodiment 3 old tea yellow tea golden flower dark tea and its processing technology

[0028] (1) Use aged yellow tea (Junshan yellow tea) as the processing raw material, add 20% of the processed aged tea quality water and stir evenly, put it in a sterilizer for sterilization at 121°C for 10 minutes, and obtain the tea base to be inoculated after cooling; ( 2) Crush the commercially available Fuzhuan tea, inoculate 1% of the weight of the tea base into the sterilized aged tea base, and stir carefully; (3) Place the inoculated tea leaves in a relatively closed environment at 23-28°C (4) After the cultivation, take out the tea leaves and place them in an oven at 70°C to dry for 2 hours to obtain the finished product of aged tea, yellow tea, golden flower and dark tea ( Figure 4 ).

[0029] The processing flow chart of aged tea Jinhua dark tea in embodiment 1-3 is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com