Molten ferroalloy granulating method

A ferroalloy and granulation technology, which is applied in the field of ferroalloy melt granulation, can solve the problems of low dehydration efficiency and large floor space, and achieve the effects of no dust adhesion, small floor space, and favorable metering and batching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

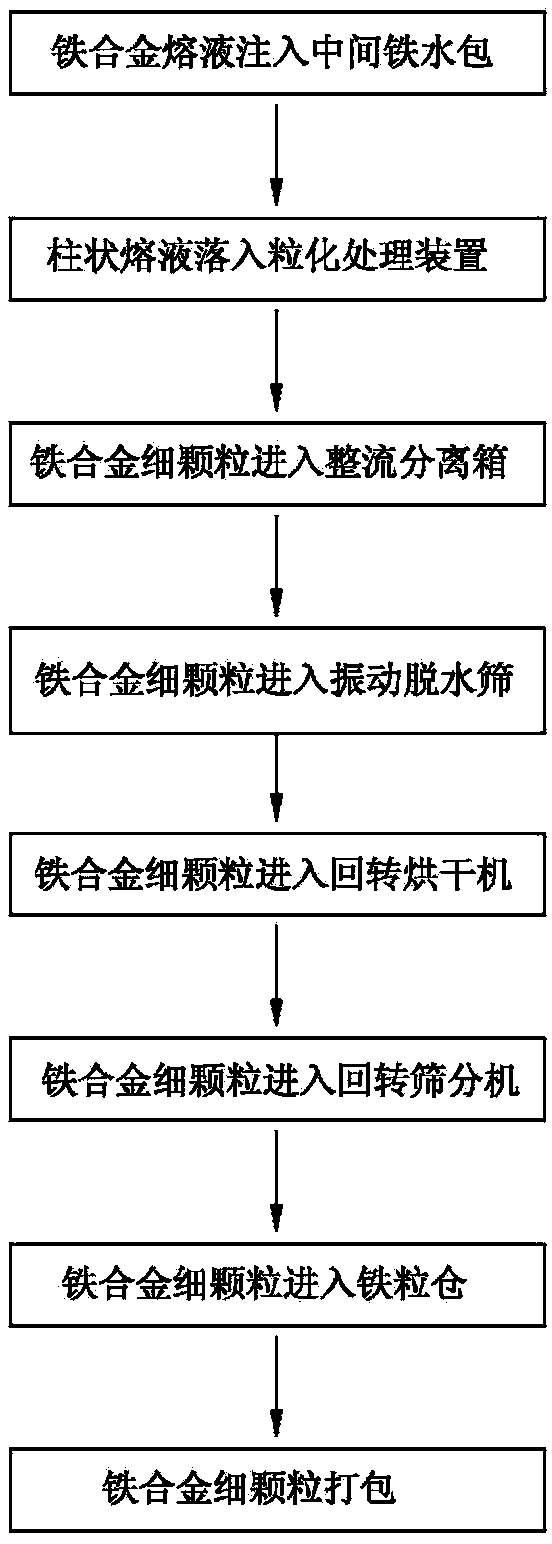

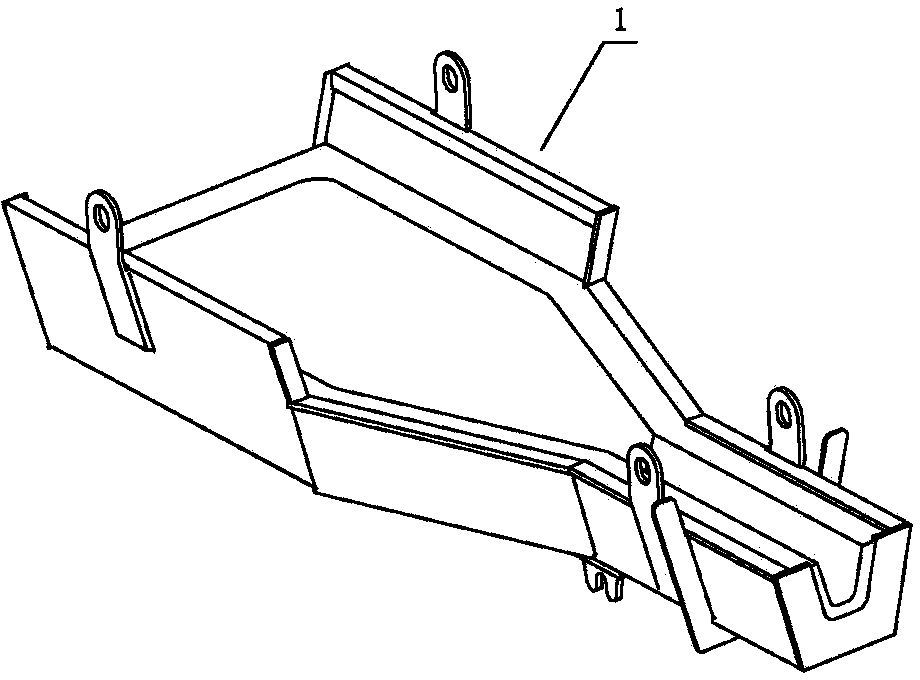

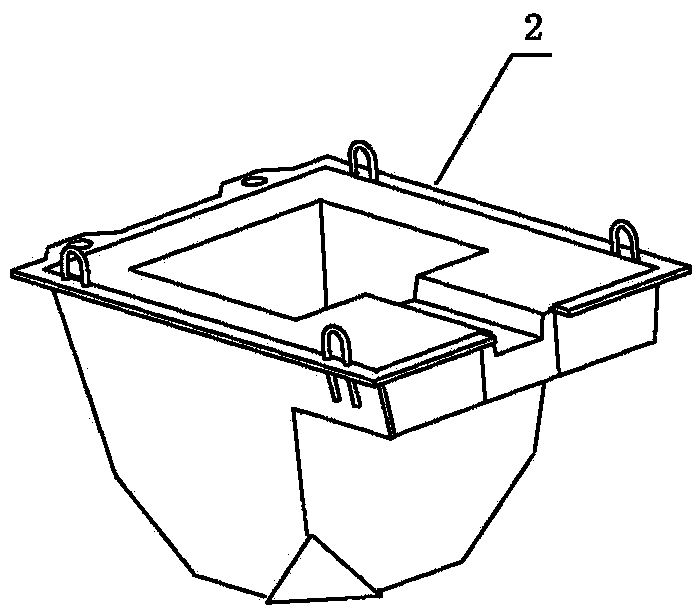

[0026] see figure 1 , the ferroalloy melt granulation method of the present invention adopts a granulation and packaging unit to produce ferroalloy fine particles, collects ferroalloy melt at 1600°C-1630°C into a molten iron tank, and transports the molten iron tank to a dumping tank through transport equipment. on the turning device; the transport equipment belongs to the prior art;

[0027] Start the tipping device to inject the ferroalloy melt into an intermediate ladle through the molten iron chute, and the bottom outlet of the intermediate ladle arranges the ferroalloy melt into a stable columnar melt flow, and the columnar ladle The flow rate of the liquid flow is 1500 kg-1600 kg per minute; the diameter of the columnar melt flow is 30 mm-45 mm, and the length (height) of the columnar melt flow is 1000-2000 mm;

[0028] Controlling the columnar melt flow to fall vertically onto a horizontal granulation disk in a granulation treatment device, and performing sputtering gr...

Embodiment 2

[0035] This embodiment is an improvement made on the basis of Embodiment 1. For the same content in this embodiment as Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description is made here; the disclosure in Embodiment 1 The content should also be taken as the content disclosed in this embodiment.

[0036] In this embodiment, in order to improve the granulation effect of the ferroalloy melt, a vertical baffle is set in the rectification and separation box, and a plurality of broken pile heads are set on the baffle, and the broken pile heads combine the solid, liquid, and Ferroalloy fine particles larger than 5 mm in the air-gas mixture fluid undergo secondary crushing. Larger particles are further crushed when they impact the crushed pile head at high speed. The structure of the broken pile head is a nipple-shaped pile head protruding from the surface of the baffle plate, and its diameter is 5-15 mm.

[0037] In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com