Welding jig overturning method and device

A technology of welding fixtures and fixtures, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable rotation, poor adjustment of impact force, and high failure rate, so as to improve the turning accuracy and turning speed, and be stable and reliable. The effect of flipping and high-precision flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

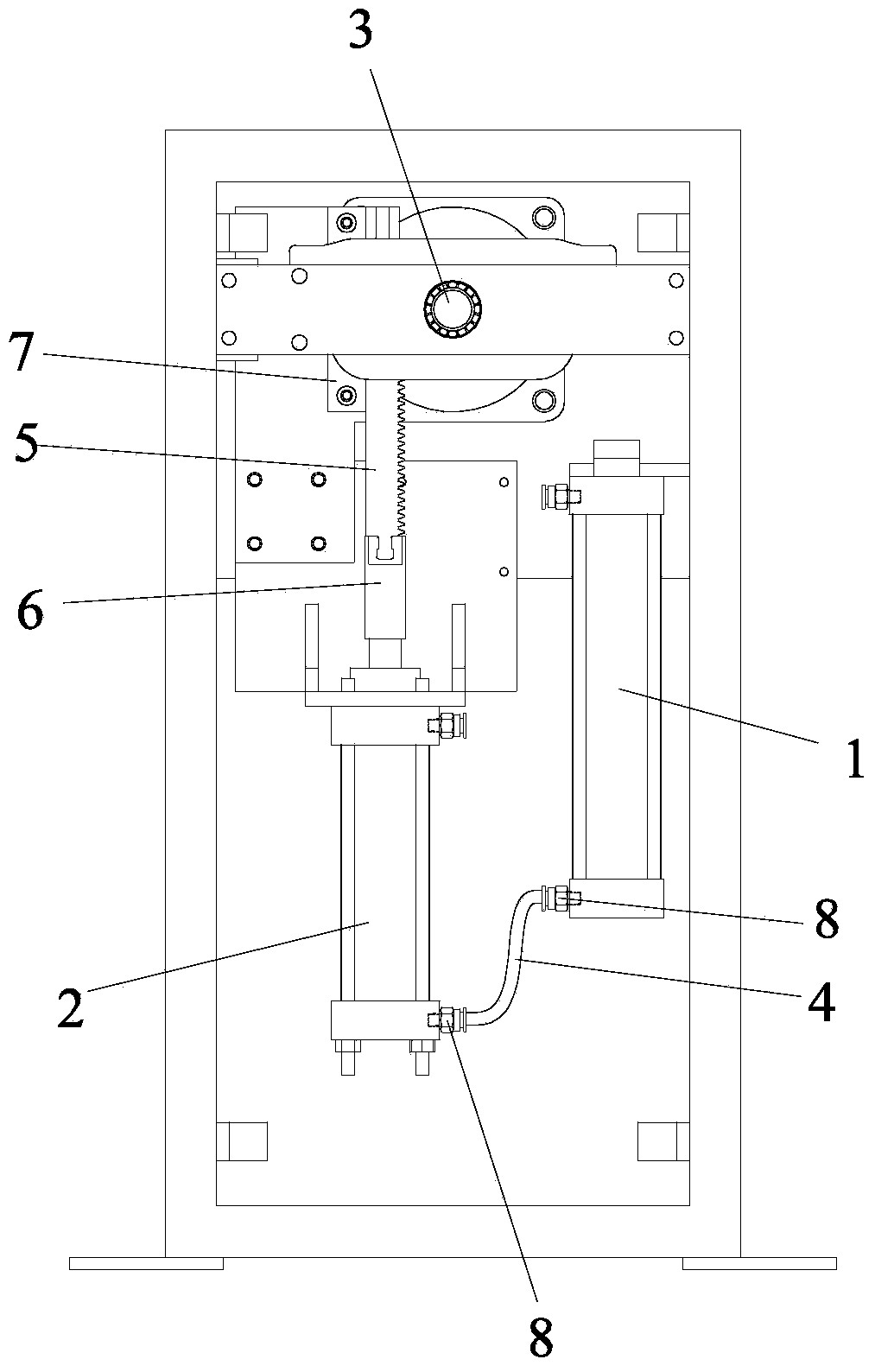

[0032] In this embodiment, the flip angle set in the first stage is 100° as an example to describe the following.

[0033] The method for turning over the welding fixture of the present invention is to control the rotating speed of the fixture main shaft 3 driving the turning of the fixture in stages through the combination of the cylinder 1 and the hydraulic cylinder 2, so as to realize the fast, stable and reliable turning of the welding fixture.

[0034] More specifically, the welding fixture flipping method includes the following two stages:

[0035] In the first stage, the compressed gas of cylinder 1 is used to push the oil in hydraulic cylinder 2, so that the hydraulic energy of hydraulic cylinder 2 can control the rotation speed of main shaft 3, and drive the fixture to turn over to the set turning angle θ; among them, the set turning angle θ is 100°.

[0036] The second stage: use the hydraulic energy of its own hydraulic cylinder 2 to control the rotation speed of the...

Embodiment 2

[0055] The only difference between this embodiment and the first embodiment is that the turning angle set in the first stage is 50°, and the method of turning over the welding jig and the devices used therefor are consistent with the first embodiment.

Embodiment 3

[0057] The only difference between this embodiment and the first embodiment is that the turning angle set in the first stage is 110°, and the method of turning over the welding jig and the devices used therefor are consistent with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com