Prefabricated hollow slab beam side formwork without performing roughing treatment

The technology of hollow slab beam and side formwork is applied in the field of prefabricated hollow slab girder side formwork, which can solve the problems of difficulty in guaranteeing the quality of surface chiseling, difficulty in artificial chiseling, and large chiseling area, so as to achieve simple and clear design ideas and shorten construction period. , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

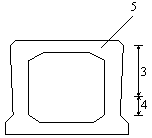

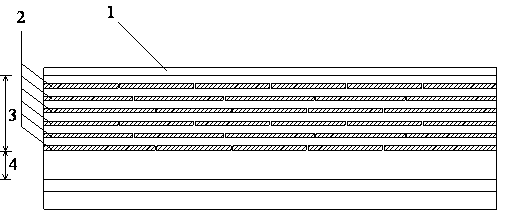

[0025] Such as Figure 1 to Figure 5 As shown, the chisel-free prefabricated hollow slab beam side formwork of the present invention includes a steel side formwork 1 and steel strips 2 . The steel side formwork 1 changes according to the size of the prefabricated hollow slab 5; the steel strip 2 is welded to the steel strip arrangement area 3 inside the side formwork 1, and the steel strip arrangement area 3 is an approximately vertical section area on the side surface of the hollow plate beam, and should avoid Area 4 of the bent section of the hinged steel bar.

[0026] In the embodiment of the present invention, the steel strips 2 have a thickness of 6mm and a width of 30mm, and are arranged in groups of three in the steel strip arrangement area. Each set of spacing is selected according to the roughness requirements and arranged in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com