Locomotive cabin self-cleaning decorating plate

A technology for decorative panels and cabins, applied in the field of self-cleaning decorative panels in locomotive cabins, can solve the problems of hidden safety hazards and low impact strength of the ceiling, and achieve the effects of improved impact strength, obvious anti-fouling effect, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

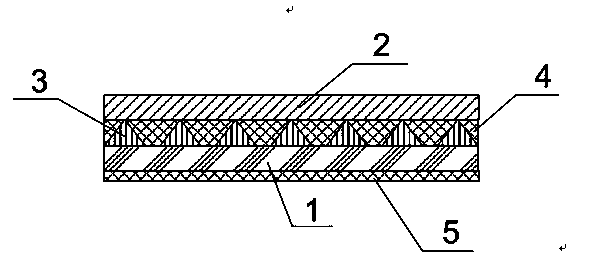

[0010] As an embodiment of the present invention, see figure 1 , the present invention comprises a plate body 1, the back side of the plate body 1 is provided with a reinforcing panel 2, a reinforcing beam 3 is arranged between the reinforcing panel 2 and the plate body 1, the reinforcing beams 3 are evenly distributed along the width direction of the plate body 1, and the reinforcing beam 3 The gap between the plate body 1 and the reinforced panel 2 is filled with an adhesive layer 4 , and the front of the panel is coated with a nanometer self-cleaning layer 5 . The cross section of the reinforcing beam 3 is triangular.

[0011] The manufacturing process of the present invention is simple, the reinforced panel 2 can play a moisture-proof function, and a reinforced beam 3 is provided between the reinforced panel 2 and the board body 1, which can improve the overall impact strength and is suitable for long-term use. The nanometer self-cleaning layer 5 is anti-pollution The eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com