Double layer flame retardation humidity-resistant environment friendly communication cable and production technology therefor

A communication cable, moisture-resistant technology, used in insulated cables, cable/conductor manufacturing, and conductor/cable insulation, etc., to reduce the outer diameter and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings, the present invention will be further described through implementation.

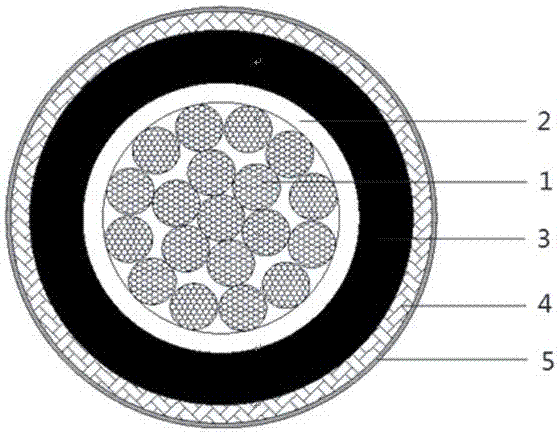

[0021] A double-layer flame-retardant, moisture-resistant and environmentally friendly communication cable, comprising a tinned annealed copper conductor 1, a high-temperature-resistant GRPP tape 2, a low-smoke, halogen-free flame-retardant polyolefin insulation 3, a braided cotton layer 4, and a flame-retardant paint coating 5. The tinned annealed copper conductor 1 is composed of 47 tinned copper wires with a diameter of 0.50 mm twisted to form a strand strand, and the twisting direction is left; the tinned annealed copper conductor is formed by twisting 19 strands of wire. 1. There is a bunch of strands in the center, 6 strands of strands are twisted in the inner layer, the twisting direction of the inner layer is right, and 12 strands of strands are twisted in the outer layer, and the twisting direction of the outer layer is left; tinned Sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com