Freeze-dried scallion filling capsule

A technology of dried chives and capsules, applied in the directions of microcapsule preparation, microsphere preparation, food science, etc., can solve the problems of reducing the value of freeze-dried products, losing bright green color, discoloration, etc., achieving stable mechanical strength, prolonging shelf life, reducing The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

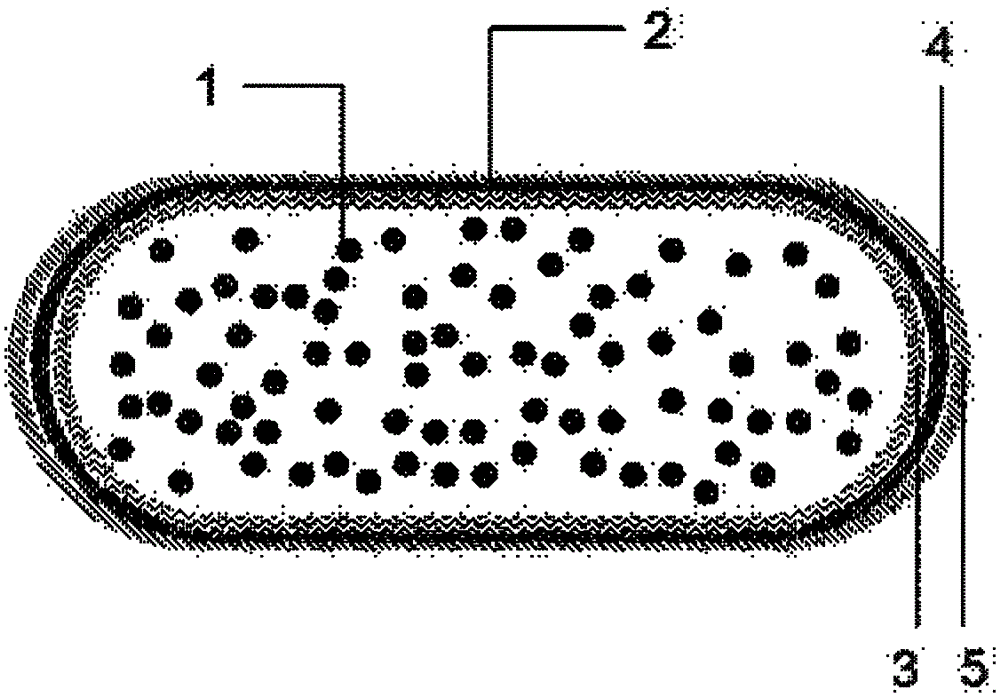

Image

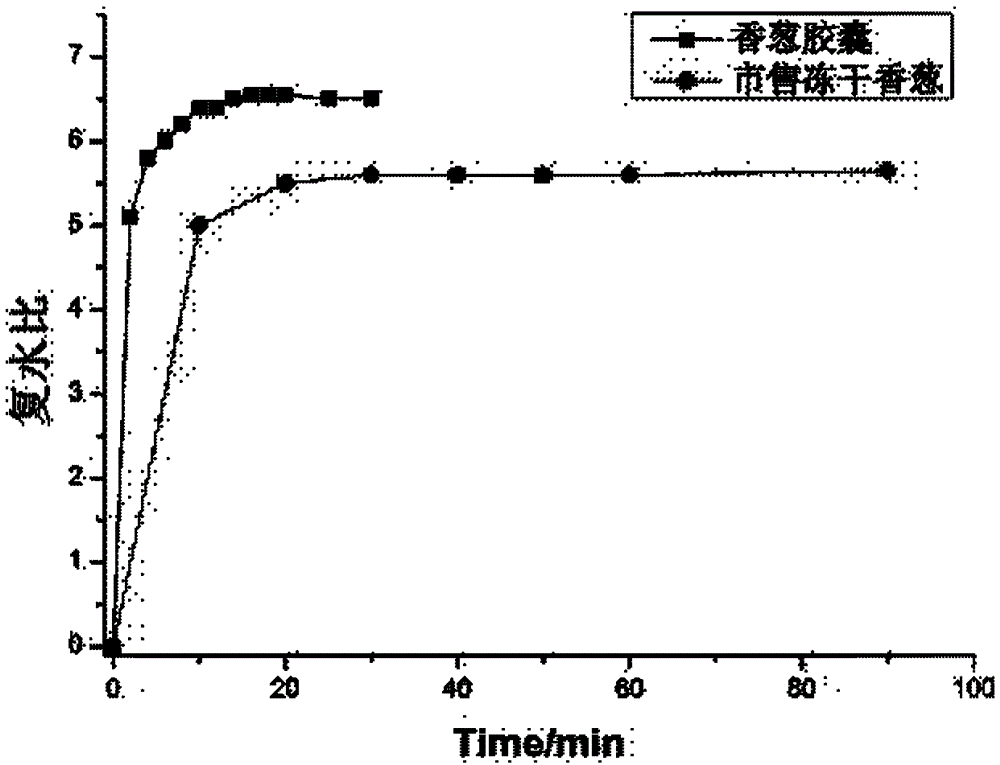

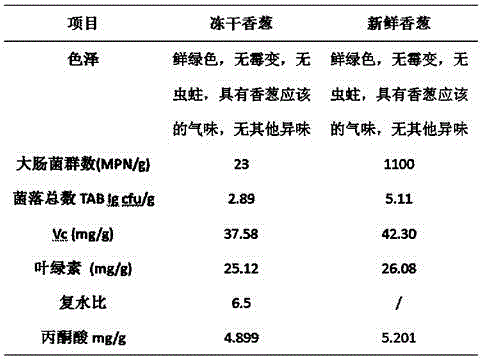

Examples

Embodiment Construction

[0041] Freeze-dried shallot capsules are specifically made by the following steps:

[0042] 1. Drying of chives:

[0043] The process is as follows:

[0044] Selective inspection: conduct sensory and pesticide residue inspections, and the rapid pesticide residue tester will test that the inhibition rate of acetylcholinesterase is <40%; the raw materials that pass the inspection are sent to the workshop for processing; unqualified products and unqualified specifications are removed Remove rotten, diseased parts, impurities and foreign objects for the products, redundant root heads, and excessively long thick and old parts;

[0045] Soaking and cleaning: the shallots are first soaked in 1% alkaline water for 6 minutes and then cleaned in multiple ways;

[0046] Rinsing: The materials are sent to the main workshop, sorted on the workbench and washed away with flowing water to remove the peeled waste and impurities;

[0047] Pelletizing: The raw materials are cut into the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com