Hydraulic-drive amphibious boat

An amphibious and hydraulic technology, applied in amphibious vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of small driving torque, increased ship failure rate, increased hull weight, etc. Effects of improving maneuverability and increasing endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

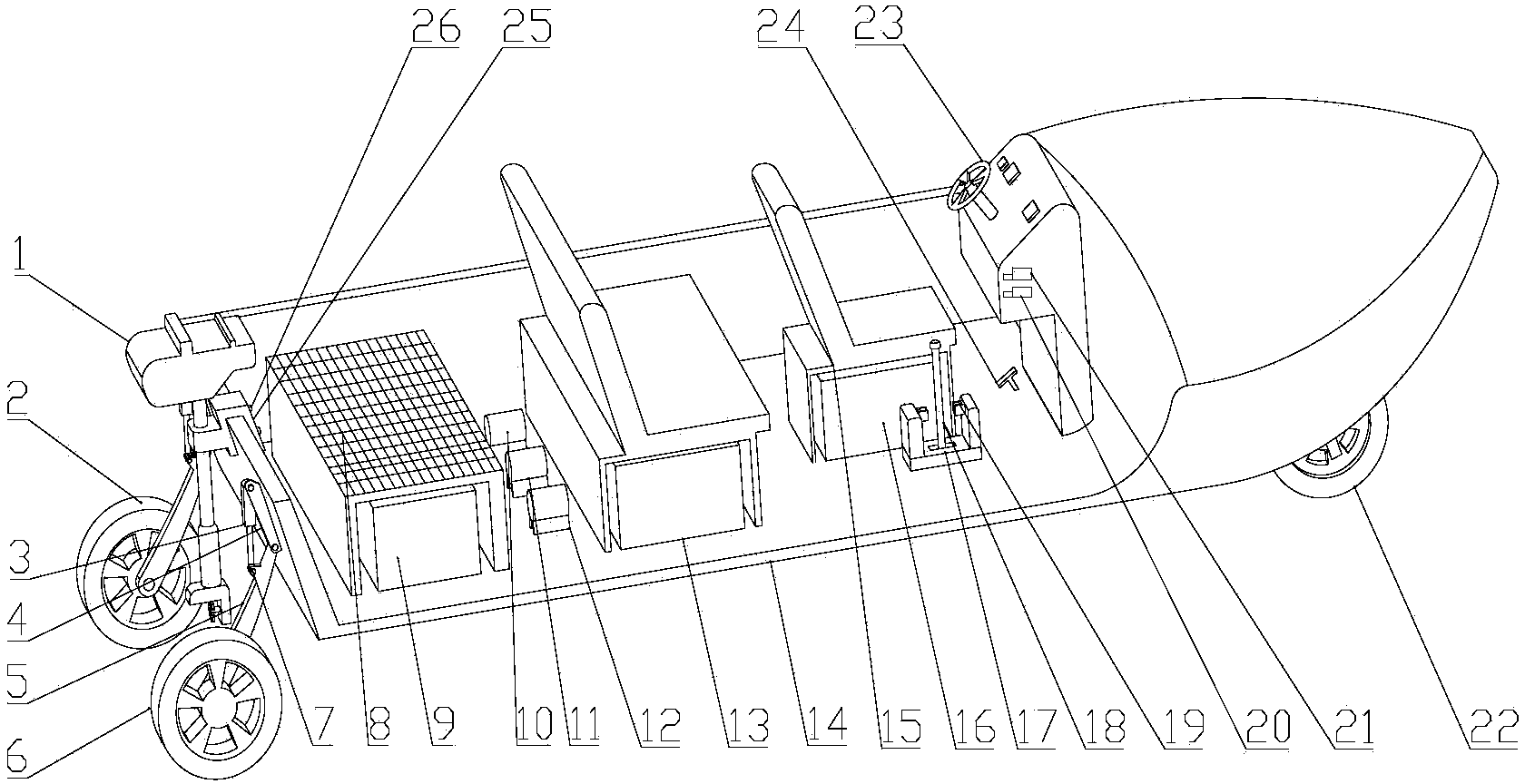

[0069] figure 1 This is the overall structure diagram of the amphibious ship (the starboard side is omitted for the convenience of observing), which shows the various components of the amphibious ship. Depend on figure 1 It can be known that the ship's water drive is driven by the outboard motor 1, the steering wheel 23 can control its direction, and the Hall type electronic accelerator pedal 24 can control the speed of the outboard motor 1 with a magnetic signal to the master controller 167. The outboard motor 1 is fixed on the hull 14 through a fixed tightening seat 25 and a fixed clamping bolt 26 .

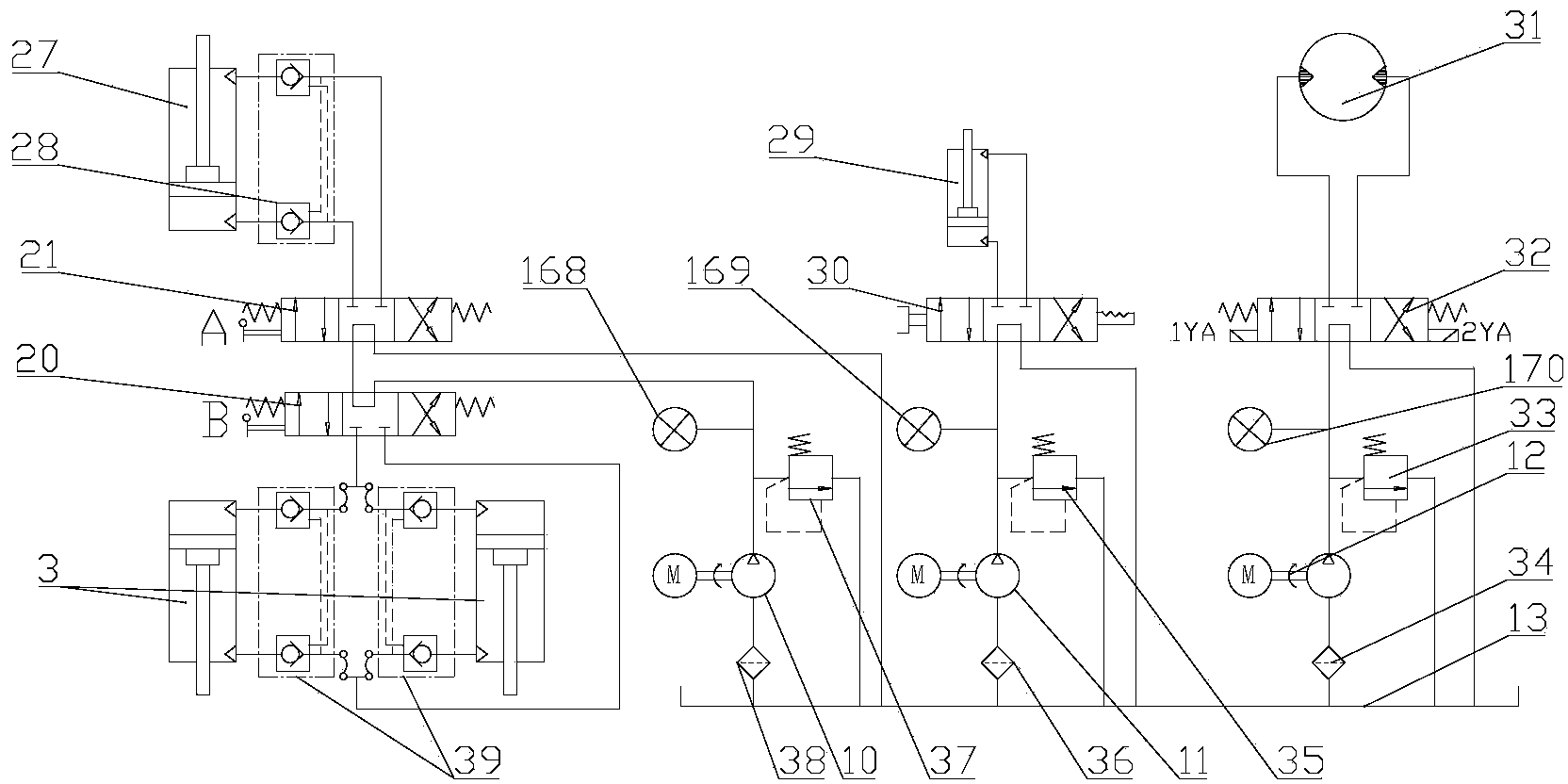

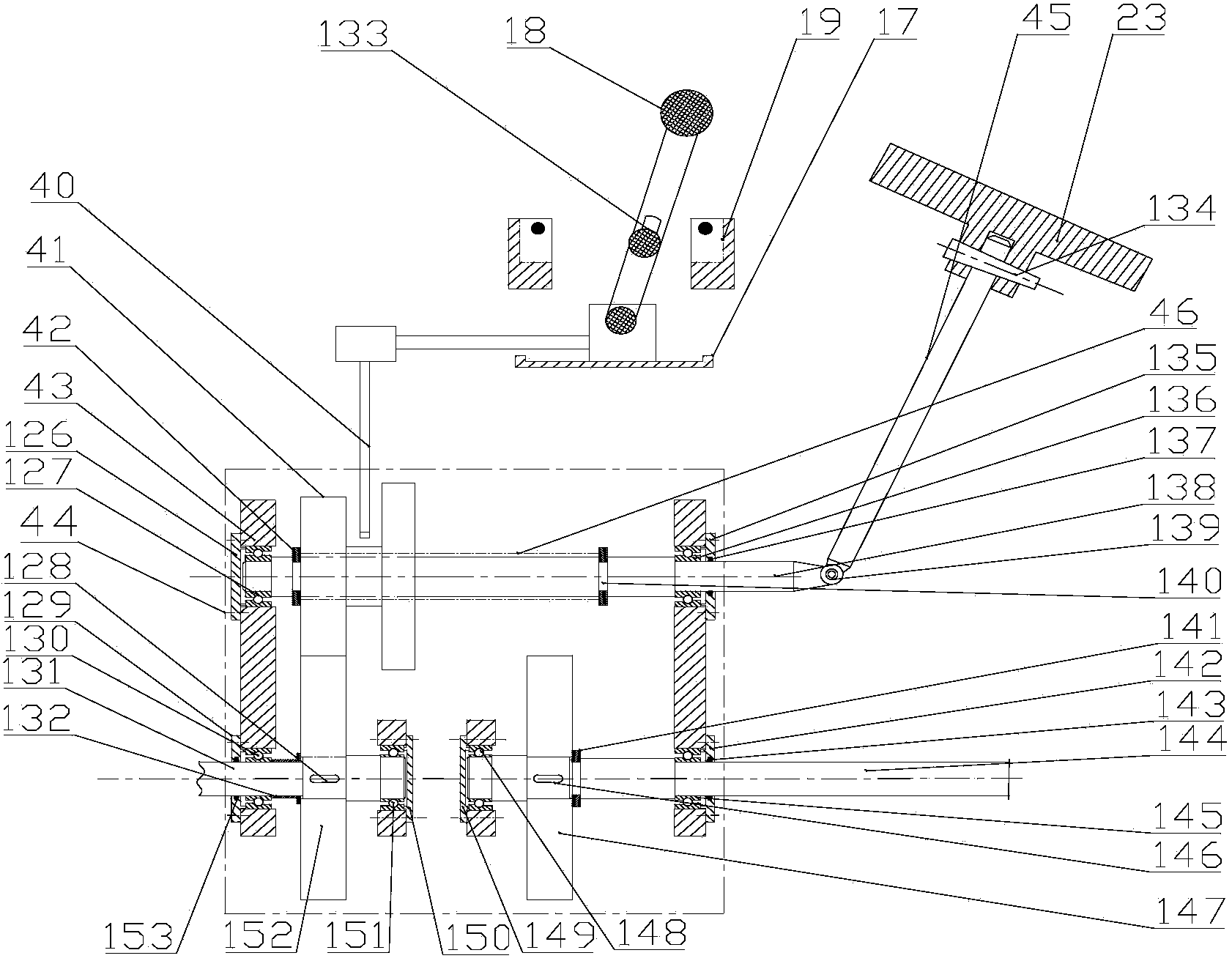

[0070] When walking on land, the hydraulic outrigger motor pump 10 starts, the conversion box lever 18 converts the transmission mode, and the front wheel manual reversing valve 21 and the rear wheel manual reversing valve 20 control the front outrigge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com