Three-degree-of-freedom space simulator

A technology of simulators and degrees of freedom, applied in the field of aerospace, can solve the problems of space simulation test equipment such as poor versatility, high maintenance costs, and complex mechanical structures, and achieve the effects of light weight, convenient maintenance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

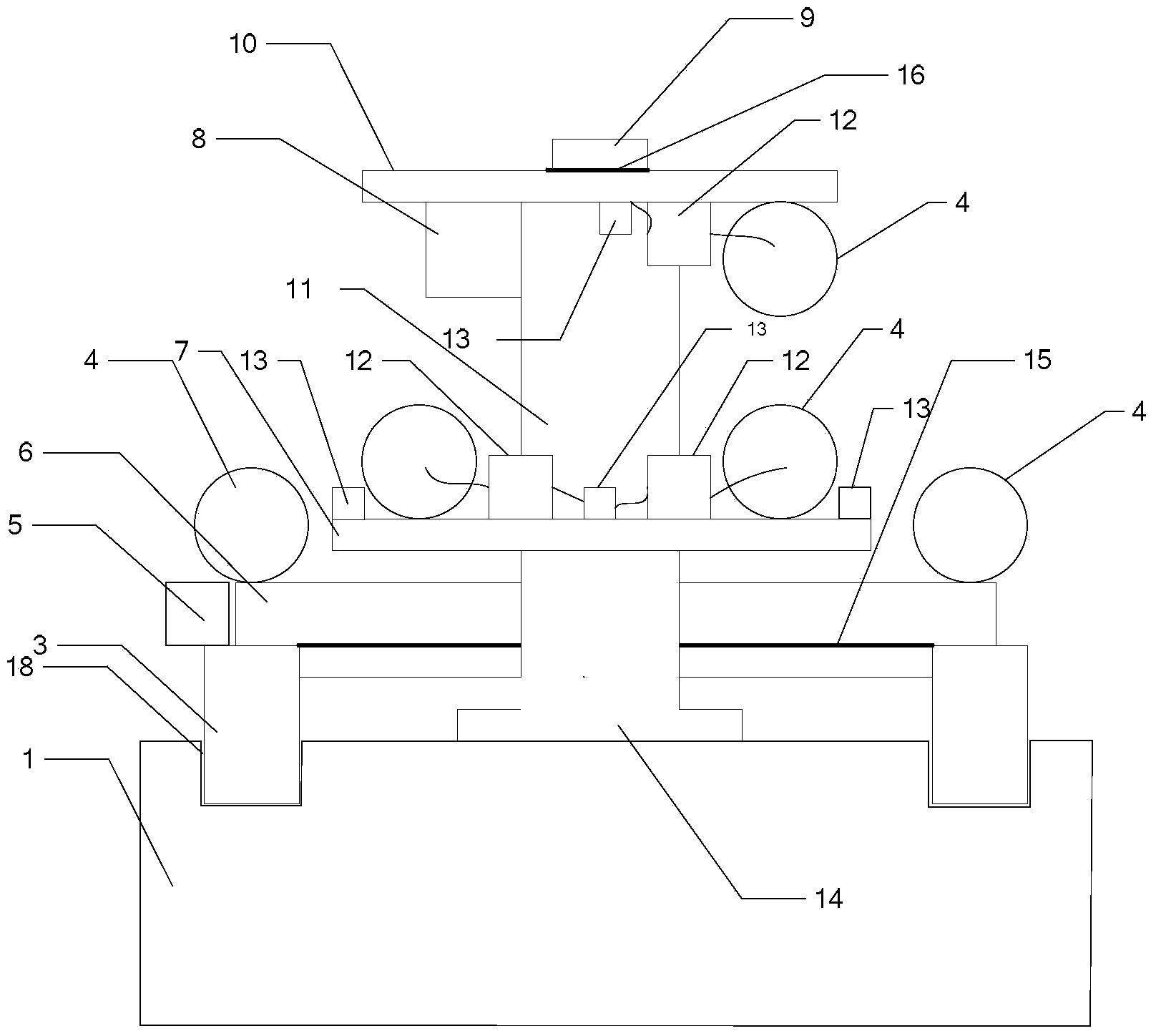

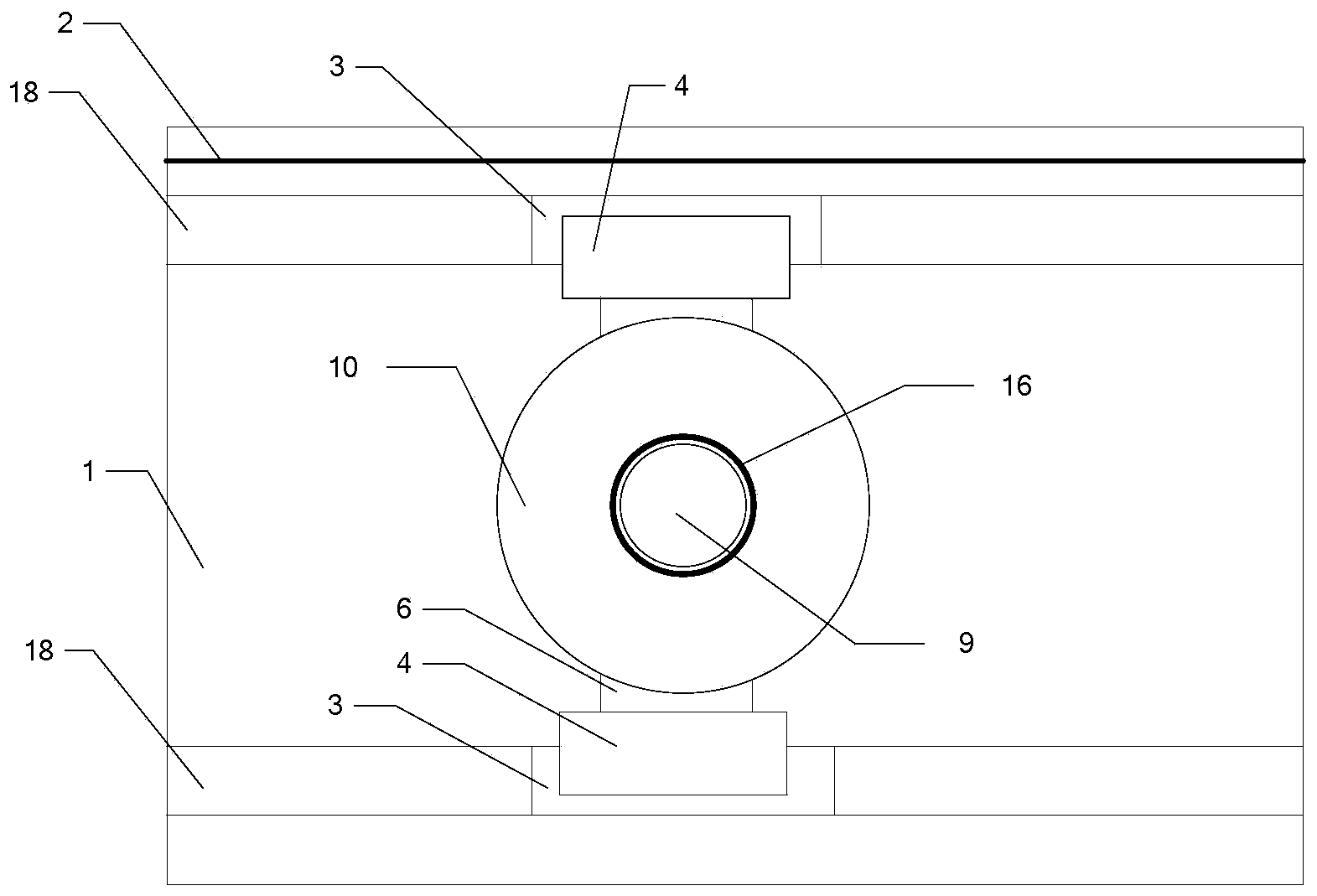

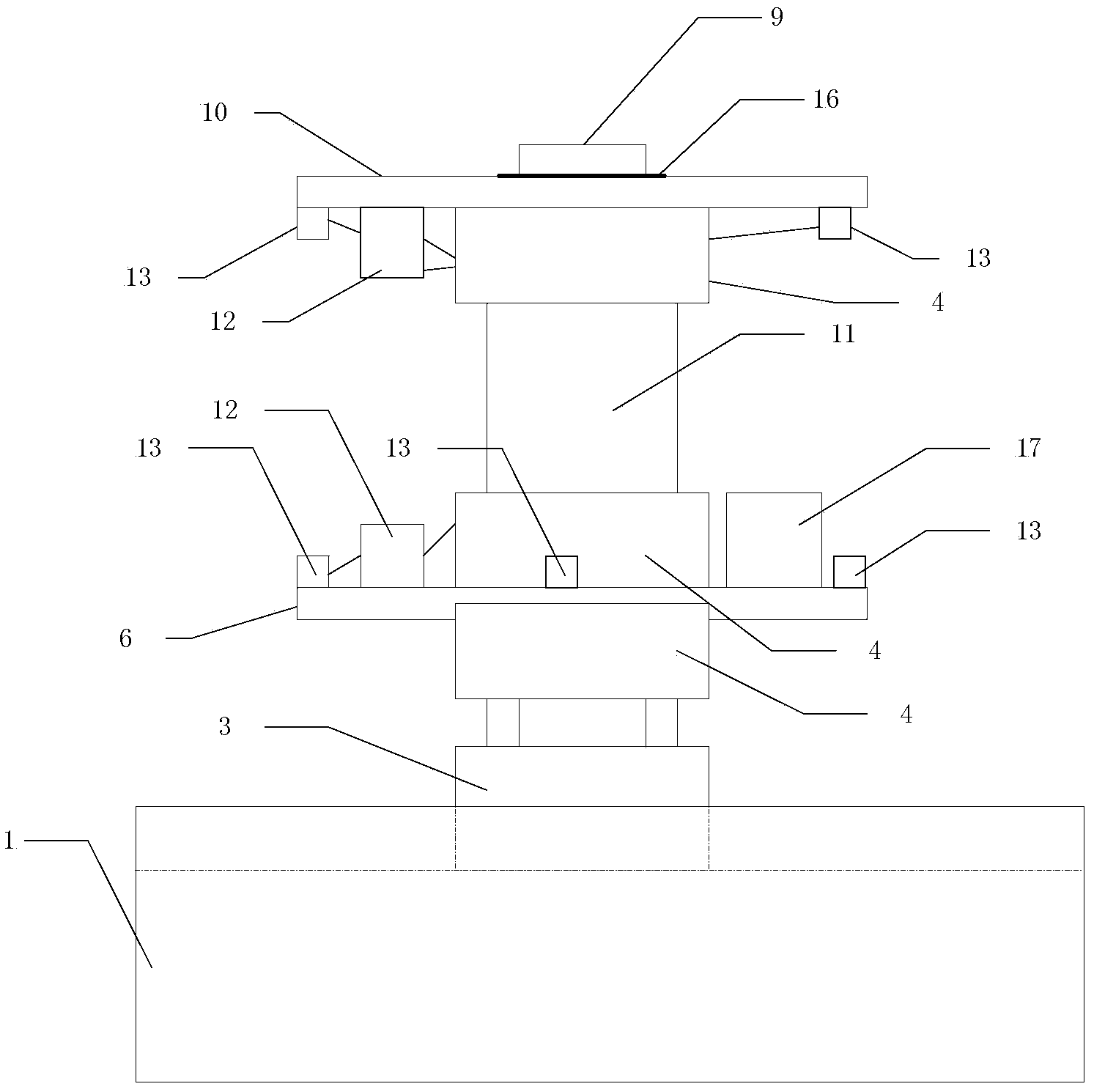

[0034] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, the three-degree-of-freedom space simulator described in this embodiment includes a base 1, an X-axis grating ruler 2, an air bearing guide rail 3, five high-pressure gas cylinders 4, an X-axis communication control module 5, a gas Floating beam 6, lower plate 7, rotary shaft communication control module 8, reaction flywheel 9, upper plate 10, rotary shaft 11, 3 pressure regulating valves 12, 6 nozzles with solenoid valves 13, air bearing sleeve 14, Y axis grating ruler 15, circular grating ruler 16 and Y-axis communication control module 17;

[0035] The top surface of the base 1 is provided with two parallel air flotation grooves 18, the air flotation beam 6 is arranged on the base 1, and the bottoms of the two ends of the air flotation beam 6 are respectively fixed with air flotation guide rails 3, and the two air flotation beams The floating guide rails 3 are res...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment is a further limitation of the three-degree-of-freedom space simulator described in Embodiment 1. The bottom of the air bearing guide rail 3 is provided with 2×6 air bearing holes with a diameter of 0.15mm. The bottom plate of the cover 14 is provided with 4×6 air flotation holes with a diameter of 0.15mm.

specific Embodiment approach 3

[0050] Embodiment 3: This embodiment is a further limitation of the three-degree-of-freedom space simulator described in Embodiment 1, and the nozzle 13 is a Laval nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com