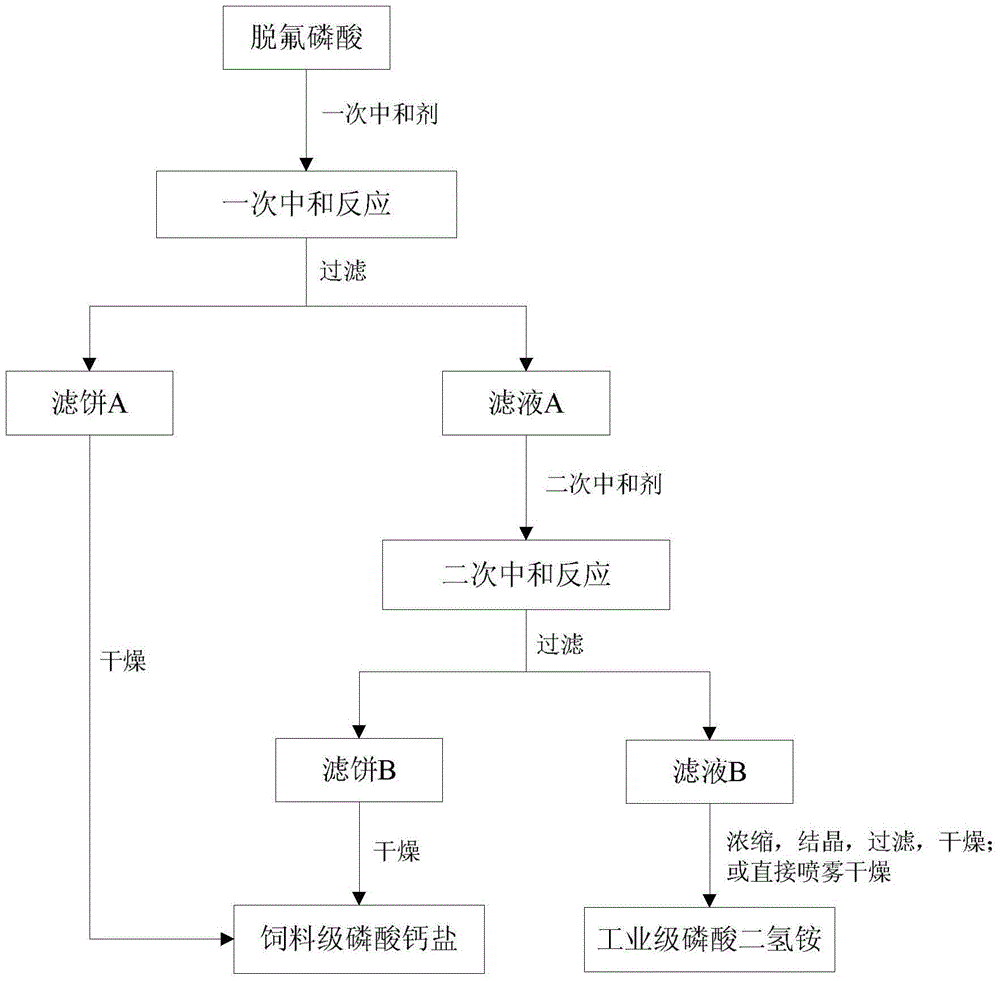

Method for co-production of industrial grade ammonium dihydrogen phosphate and feed grade calcium phosphate by defluorinated phosphoric acid

A technology of high-grade ammonium dihydrogen phosphate and defluorinated phosphoric acid, which is applied in the fields of phosphate, chemical instruments and methods, phosphorus oxyacids, etc., can solve the problems of low utilization of raw materials, large losses, and unsatisfactory economic value, and achieve Good social and economic benefits, high utilization of raw materials, high nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] a.P 2 o 5 In 1000g of defluorophosphoric acid with a concentration of 28.51%, 90g of calcium oxide is added in a certain proportion to carry out a neutralization reaction. Calcium oxide and P in defluorophosphoric acid 2 o 5 The molar ratio is 0.8:1, the reaction temperature is controlled at 62°C, the reaction time is 1h, and solid-liquid separation is obtained to obtain filtrate A and filter cake A; wherein, filtrate A is calcium dihydrogen phosphate solution, and filter cake A is precipitated by calcium phosphate salt .

[0064] b. Perform a secondary neutralization reaction on the filtrate A obtained in step a and ammonia water, control the reaction temperature at 67°C, and the reaction time is 1.5h. When the pH of the reaction solution is adjusted to 4.2, control the reaction to end and separate the solid and liquid to obtain the filtrate B And filter cake B, the component of filtrate B is ammonium dihydrogen phosphate solution, and filter cake B is precipitated ...

Embodiment 2

[0072] a.P 2 o 5 In 1000g of defluorophosphoric acid with a concentration of 35.53%, 140g of calcium oxide is added in a certain proportion to carry out a neutralization reaction. Calcium oxide and P in defluorophosphoric acid 2 o 5 The molar ratio is 1.0:1, the reaction temperature is controlled at 64°C, the reaction time is 1h, and solid-liquid separation is obtained to obtain filtrate A and filter cake A; wherein, filtrate A is calcium dihydrogen phosphate solution, and filter cake A is precipitated by calcium phosphate salt .

[0073]b. Perform a secondary neutralization reaction on the filtrate A obtained in step a and ammonia water, control the reaction temperature at 68°C, and the reaction time is 1.7h. When the pH of the reaction solution is adjusted to 4.4, control the reaction to end and separate the solid and liquid to obtain the filtrate B And filter cake B, the component of filtrate B is ammonium dihydrogen phosphate solution, and filter cake B is precipitated ...

Embodiment 3

[0081] a.P 2 o 5 In 1000g of defluorophosphoric acid with a concentration of 43.72%, 273g of calcium hydroxide is added in a certain proportion to carry out a neutralization reaction. Calcium hydroxide and P in defluorophosphoric acid 2 o 5 The molar ratio is 1.2:1, the reaction temperature is controlled at 64°C, the reaction time is 1h, and solid-liquid separation is obtained to obtain filtrate A and filter cake A; wherein, filtrate A is calcium dihydrogen phosphate solution, and filter cake A is precipitated by calcium phosphate salt .

[0082] b. Perform a secondary neutralization reaction on the filtrate A obtained in step a and ammonia water, control the reaction temperature at 71°C, and the reaction time is 1.9h. When the pH of the reaction solution is adjusted to 4.5, control the reaction to end and separate the solid and liquid to obtain the filtrate B And filter cake B, the component of filtrate B is ammonium dihydrogen phosphate solution, and filter cake B is prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com