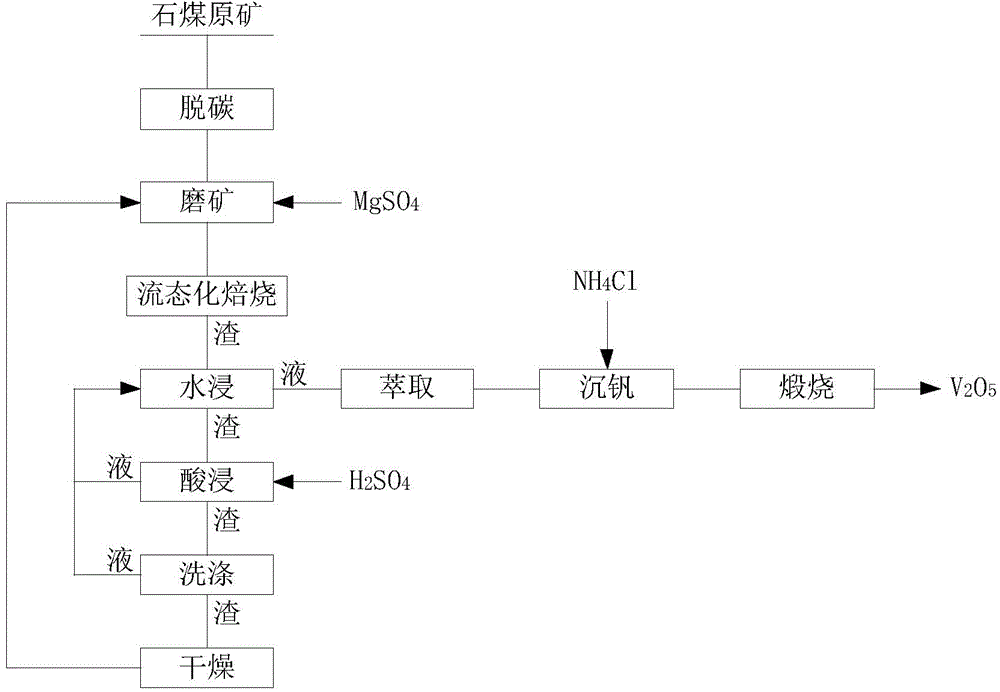

Method for recovering vanadium by virtue of magnesiation and roasting of stone coal

A fluidized roasting and roasting technology, which is applied in the field of mineral processing, can solve the problems of large tail gas emissions, achieve low production costs, reduce harmful gas emissions, and reduce water and acid consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A certain stone coal ore in Hunan Province containing 1.57% vanadium was placed in a fluidized bed, and was roasted and decarburized by passing air at 750°C for 1 hour to obtain roasted slag; 4 The roasted slag after decarburization was added and mixed to -100 mesh to account for 80%, and the ore sample was placed in a circulating fluidized bed for fluidized roasting at a roasting temperature of 800°C and a roasting time of 3 hours; leaching with distilled water at 80°C at a liquid-solid ratio of 15mL / g for 2.5h and then filtering to obtain a vanadium-containing leaching solution. The filter residue was pickled with 20% sulfuric acid at 80°C for 2 hours. The acid leaching slag was washed 3 times with distilled water, and the washing liquid was mixed with the acid leaching liquid and used as the leaching agent for the roasted sample. After the washing slag was dried, it was mixed with the newly prepared stone coal decarburization roasting slag at a mass ratio of 10%, and...

Embodiment 2

[0031] A certain stone coal ore in Guangxi containing 1.11% vanadium was placed in a circulating fluidized bed, and was roasted and decarburized by air at 700°C for 0.5h to obtain roasted slag; 4 The decarburized roasted slag was added and mixed until -100 mesh accounted for more than 80%, and the ore sample was placed in a circulating fluidized bed for fluidized roasting at a roasting temperature of 800°C and a roasting time of 2 hours; The vanadium-containing leaching solution was obtained by leaching with distilled water at 60°C under pressure at a liquid-solid ratio of 10mL / g for 4h and then filtering. The filter residue was pickled with 30% sulfuric acid at 60°C for 2 hours. The acid leaching slag was washed 5 times with distilled water, and the washing liquid was mixed with the acid leaching liquid and used as a leaching agent for the roasted sample. After the washing slag was dried, it was mixed with the newly prepared stone coal decarburization roasting slag at a mass ...

Embodiment 3

[0033] A certain stone coal ore in Guizhou containing 1.72% vanadium was placed in a fluidized bed and decarburized by passing air at 800°C for 1 hour to obtain roasted slag; 4 The roasted slag after decarburization was added and mixed until -100 mesh accounted for more than 80%, and the ore sample was placed in a circulating fluidized bed for fluidized roasting at a roasting temperature of 700°C and a roasting time of 6 hours; The vanadium-containing leaching solution was obtained by leaching with distilled water at 90°C under pressure at a liquid-solid ratio of 20mL / g for 2h and then filtering. The filter residue was pickled with 10% sulfuric acid at 90°C for 4 hours. The acid leaching slag was washed 3 times with distilled water, and the washing liquid was mixed with the acid leaching liquid and used as the leaching agent for the roasted sample. Roasted slag mass 20% MgSO 4 Carry out ore grinding, and then further obtain vanadium-containing leaching solution through the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com