Method for purifying tetrapropylammonium hydroxide based on diffusion dialysis

A technology of tetrapropylammonium hydroxide and diffusion dialysis, which is applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of poor purification and treatment effect of tetrapropylammonium hydroxide, environmental impact, etc., and improve convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

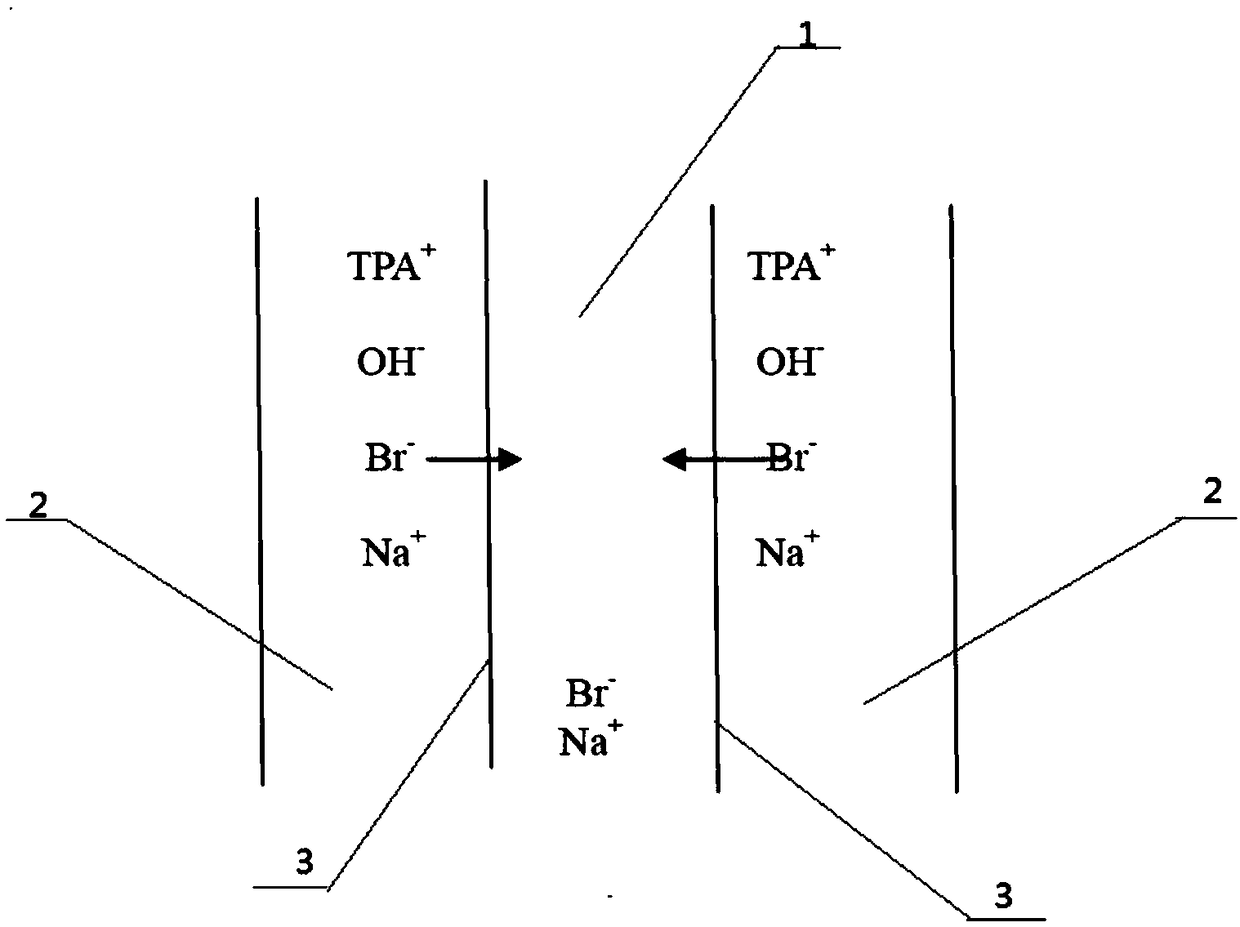

[0014] A kind of purification method based on the tetrapropyl ammonium hydroxide of diffusion dialysis, it adopts such as figure 1 The shown diffusion dialysis device is purified, and the diffusion dialysis device includes an alkali chamber 2, a water chamber 1 and an anion exchange membrane 3 arranged between the alkali chamber and the water chamber, wherein the effective area of the anion exchange membrane is 120.7cm 2 . 250ml of tetrapropylammonium hydroxide with a molar concentration of 0.66mol / L was added to the alkali chamber, and 250ml of deionized water was added to the water chamber for treatment for 100 hours to complete the purification of tetrapropylammonium hydroxide.

[0015] The molar concentration of tetrapropylammonium hydroxide obtained in the final water compartment is 0.32*10 -2 mol / L, wherein, the concentration of bromide ion is 450ppm; Tetrapropyl ammonium hydroxide molar concentration is 0.63mol / L in the alkali chamber, and wherein, the concentration ...

Embodiment 2

[0017] The diffusion dialysis device of the present embodiment is the same as that of Example 1, except that adding a molar concentration of 1.0mol / L tetrapropyl ammonium hydroxide 250ml in the alkali chamber and adding 250ml of deionized water in the water chamber; After the same time, the molar concentration of tetrapropylammonium hydroxide obtained in the water chamber is 0.60*10 -2 mol / L, wherein the concentration of bromide ions is 600ppm; the molar concentration of tetrapropylammonium hydroxide in the alkali chamber is 0.9mol / L, wherein the concentration of bromide ions is 65.5ppm.

Embodiment 3

[0019] The diffusion dialysis device of the present embodiment is the same as that of Example 1, except that 250 ml of tetrapropylammonium hydroxide of 1.25 mol / L is added in the alkali chamber, and 250 ml of deionized water is added in the water chamber; the treatment is the same as in Example 1 After the same time, the molar concentration of tetrapropylammonium hydroxide obtained in the water chamber is 1.0*10 -2 mol / L, wherein, the concentration of bromide ion is 650ppm; Tetrapropyl ammonium hydroxide molar concentration is 1.24mol / L in the alkali chamber, and wherein, the concentration of bromide ion is 95ppm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com