Evaporation mask, evaporation system and material purification method

A technology of masking and evaporation, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problems of increased cost and waste in panel factories, achieve the maintenance of background vacuum and improve utilization efficiency, and the effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

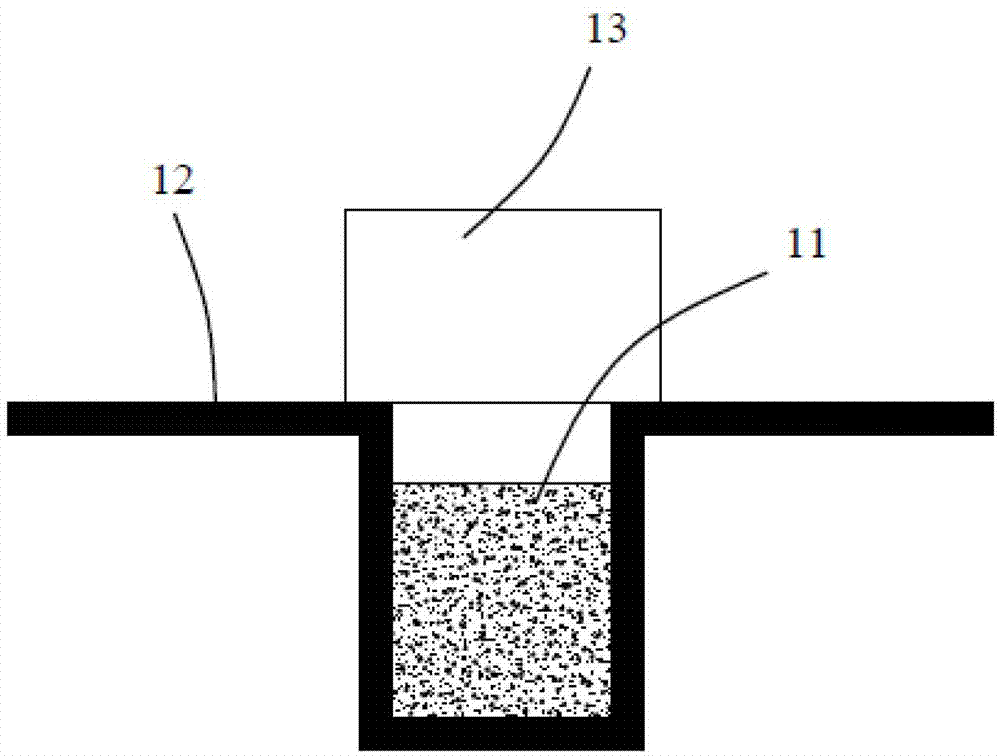

[0050] ginseng figure 1 As shown, the evaporation system includes an evaporation source 11 , a heater 12 for heating the evaporation source, and an evaporation mask 13 located above the evaporation source 11 .

[0051] The evaporation source 11 is an organic small molecule material.

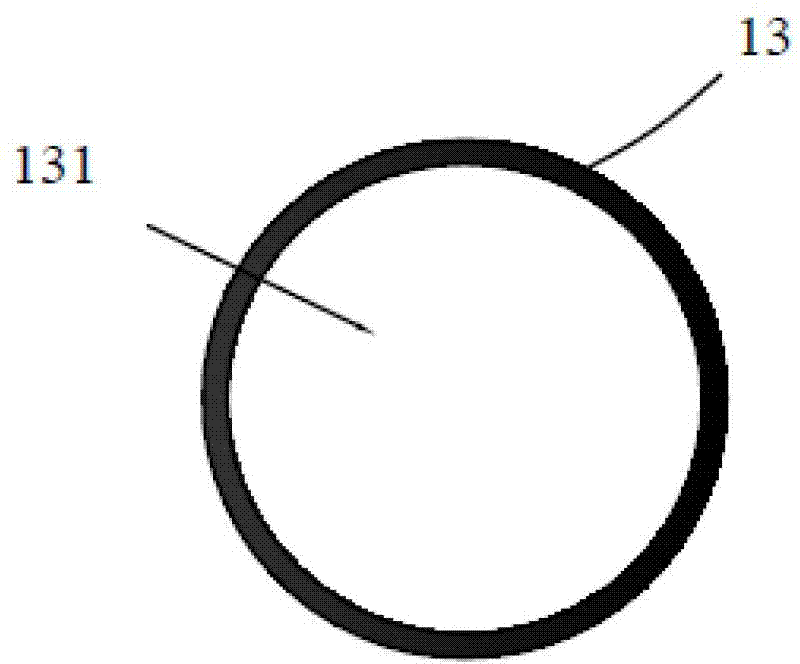

[0052] Evaporation mask 13 adopts glass, quartz, magnesium fluoride (MgF 2 ) or calcium fluoride (CaF 2 ) and other materials with the same thermal expansion coefficient as the heating substrate or below it as an evaporation mask. The evaporation mask 13 is placed on the evaporation source, the main body is a tubular structure, and its cross section is circular. figure 2 shown. The evaporation mask 13 includes an opening 131 .

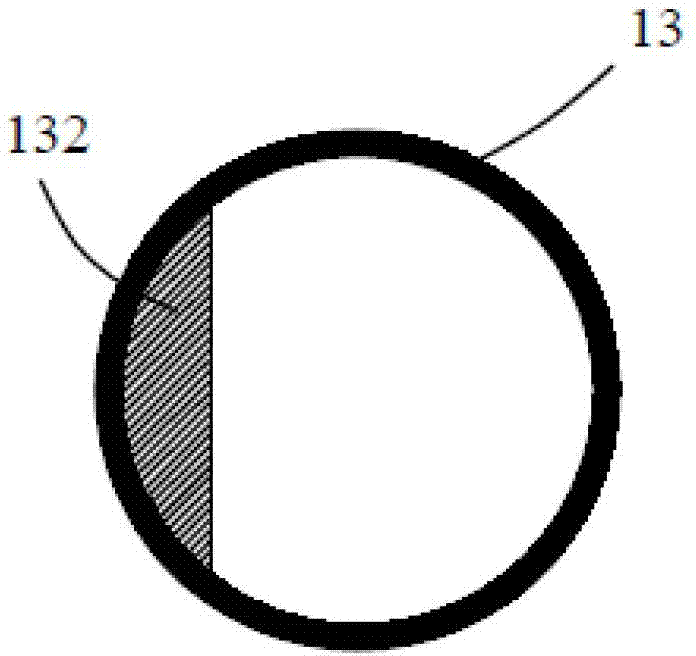

[0053] ginseng image 3 As shown, in other embodiments, the opening 131 is also covered with a shielding part 132, and the shielding part 132 shields part of the space of the opening 131, which is used to control the radiation angle of the evaporated substance from t...

Embodiment 2

[0058] ginseng Figure 5 As shown, the evaporation system includes an evaporation source 21 , a heater 22 for heating the evaporation source, and an evaporation mask 23 located above the evaporation source 21 .

[0059] The evaporation source 21 is an organic small molecule material.

[0060] Evaporation mask 23 adopts glass, quartz, magnesium fluoride (MgF 2 ) or calcium fluoride (CaF 2 ) and other materials with the same thermal expansion coefficient as the heating substrate or below it as an evaporation mask. The evaporation mask 23 is placed on the evaporation source, the main body is a tubular structure, and its cross section is rectangular. Figure 6 shown. The evaporation mask 23 includes an opening 231 .

[0061] ginseng Figure 7 As shown, in other embodiments, the opening 231 is also covered with a shielding portion 232, and the shielding portion 232 shields part of the space of the opening 231, which is used to control the radiation angle of the evaporated sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com