Semi-flexible pavement base material and preparation method thereof

A semi-flexible pavement and base material technology, applied in the field of road paving materials, can solve the problems of low fatigue resistance, inability to interweave asphalt binders, and low fluidity, so as to improve bearing capacity and compressive performance, and improve fatigue resistance. and durability, good anti-rutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

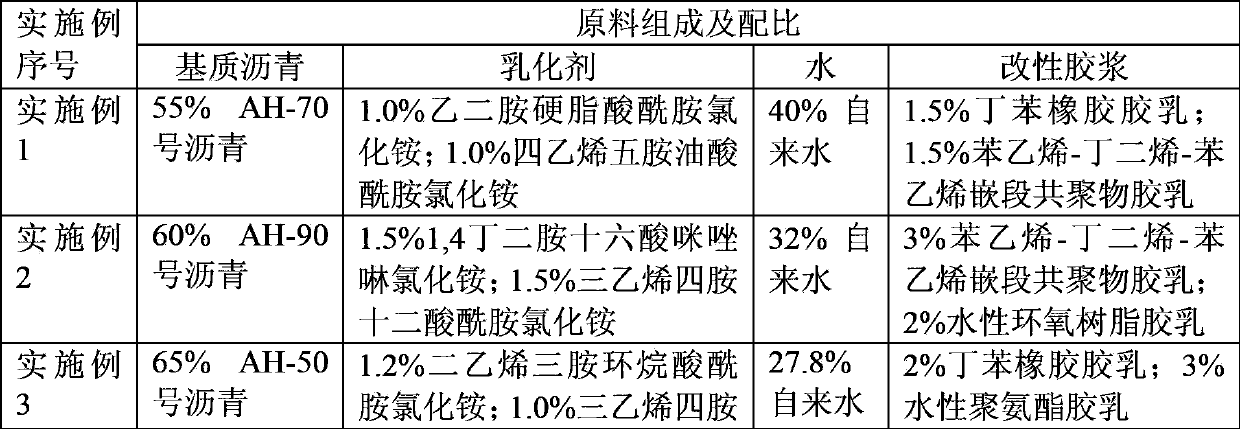

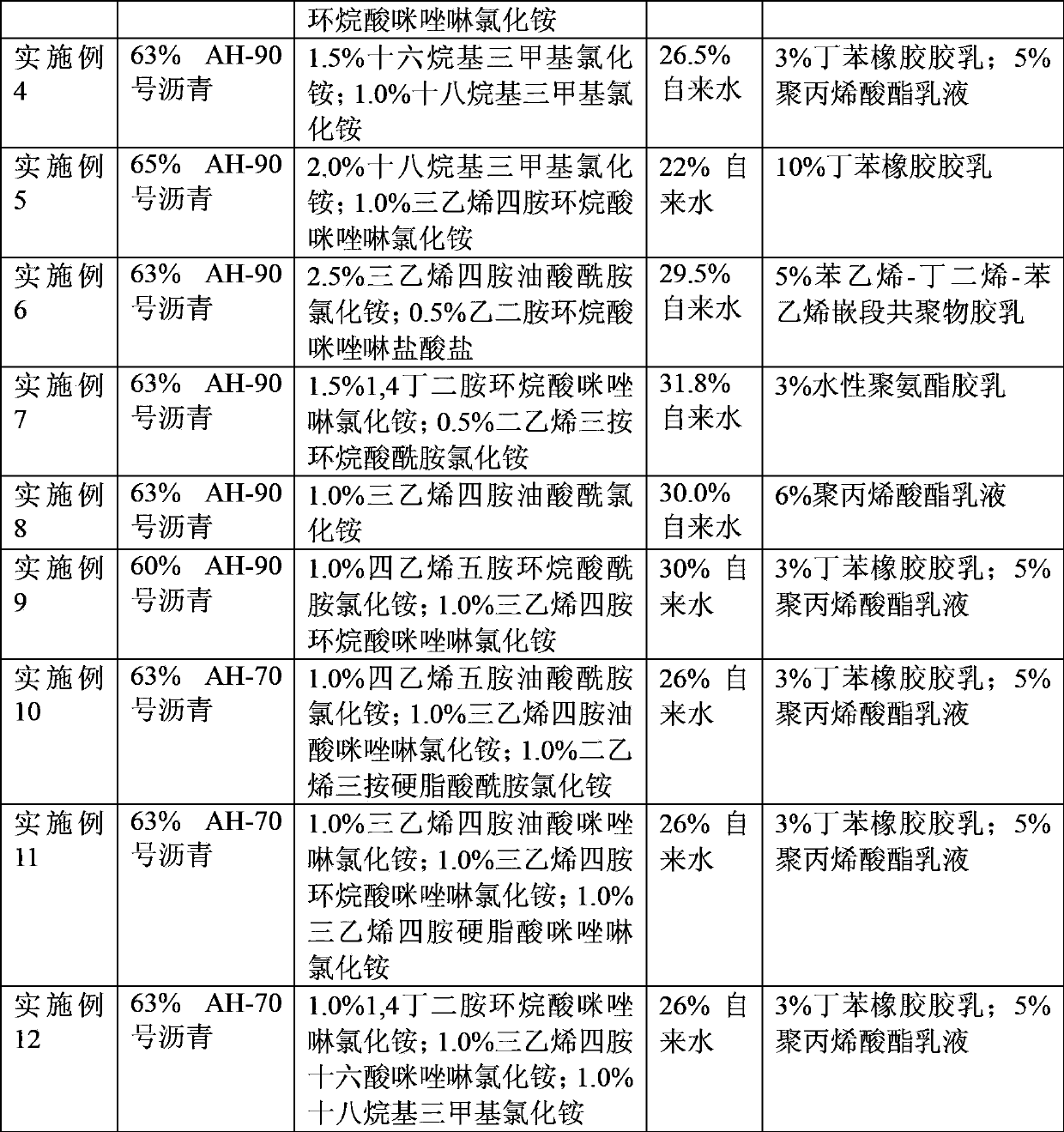

Embodiment 1~12

[0052] 1) Determination of aggregate gradation

[0053] The ore is crushed and screened, and the coarse aggregate and fine aggregate are mixed according to a certain ratio to obtain the synthetic aggregate with the mixing ratio in Table 1 below, wherein the physical properties of the coarse aggregate and fine aggregate meet the requirements in Table 2 below skills requirement:

[0054] Table 1 Aggregate grading range

[0055] Mesh size mm

26.5

19

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Basalt passing rate,%

100

93

65

55

45

26

15

10

7

3

1

0

Limestone passing rate,%

100

98

75

70

60

35

22

12

8

4

2

0

Diabase passing rate,%

100

95

70

65

55

35

20

15

10

5

3

1

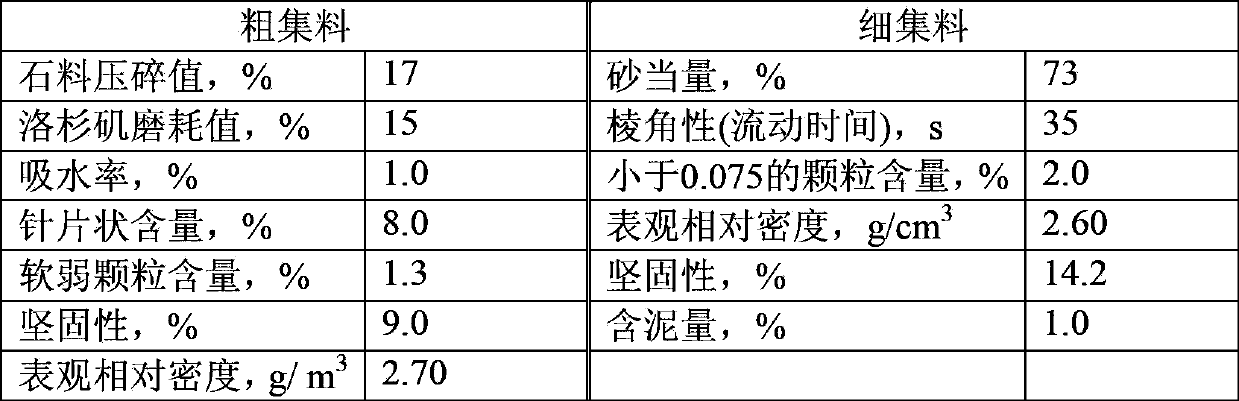

[0056] Table 2 Physical and chemical properties of coarse aggregate and fine aggregate

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com