Biomass gasifier with grate bars capable of rotating to discharge ash

A gasifier and biomass technology, applied in fixed bed gasification, manufacture of combustible gas, petroleum industry, etc., can solve the problems of wasting raw materials, reducing production efficiency, and unable to solve ash slagging, etc., to reduce energy waste and improve Production efficiency, the effect of preventing material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

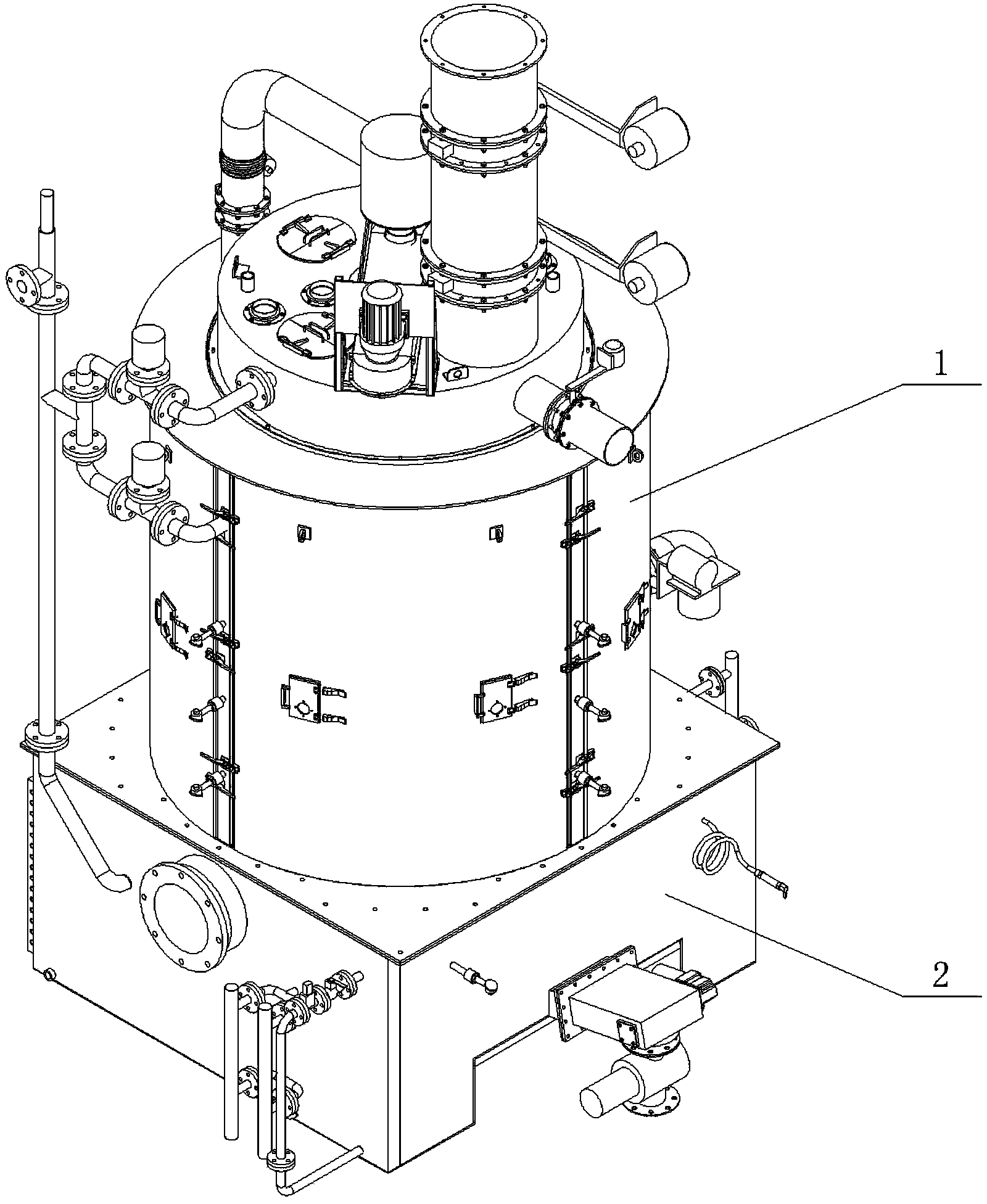

[0033] The biomass gasifier described in the present invention has a structure such as figure 1 As shown, including the upper furnace body 1 and the lower furnace body 2, the upper and lower furnace bodies are the common structure of the gasification furnace. Generally speaking, the function of the upper furnace body 1 is mainly to burn biomass particles, and the lower furnace body 2 The functions can carry out ash discharge, air extraction, etc. Certainly, the upper furnace body 1 and the lower furnace body 2 can also be collectively referred to as the furnace body. The design concept is illustrated with an example.

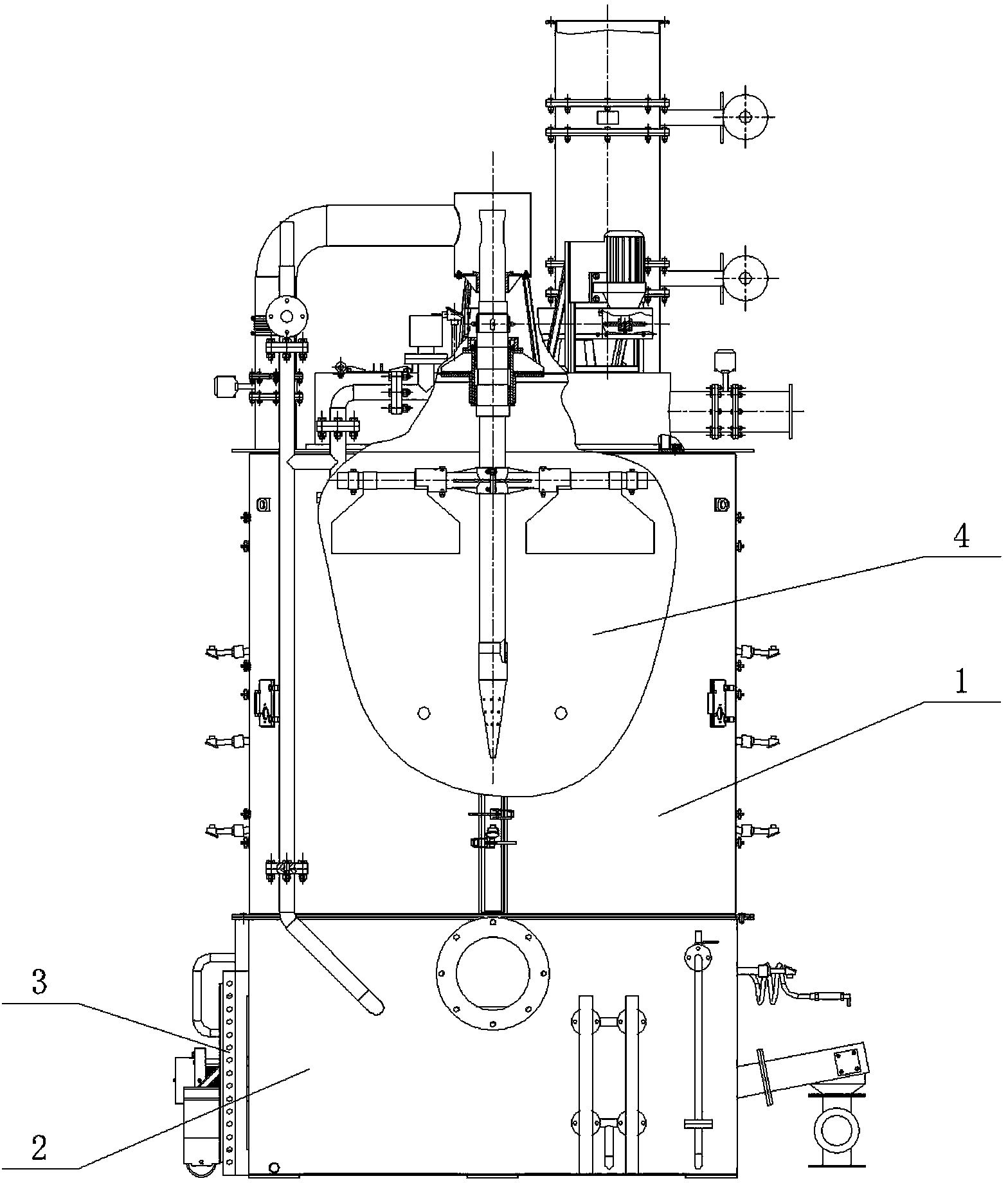

[0034] In the present invention, as figure 2 , Figure 4 As shown, the upper furnace body 1 is provided with a furnace chamber 4 for burning biomass particles, the furnace chamber 4 communicates with the lower furnace body 2, and a grate is arranged at the opening at the lower end of the furnace chamber 4, and the grate is composed of several furnace bars 5 ...

Embodiment 2

[0045] In this embodiment, the furnace bar is a solid body, and the inside is no longer cooled by cooling water, but the furnace bar needs to be made of high temperature resistant materials, such as steel, ceramics or other materials. The arrangement of the head teeth row, and the transmission part between the fire bars can adopt the same structure as that of Embodiment 1.

[0046]

Embodiment 3

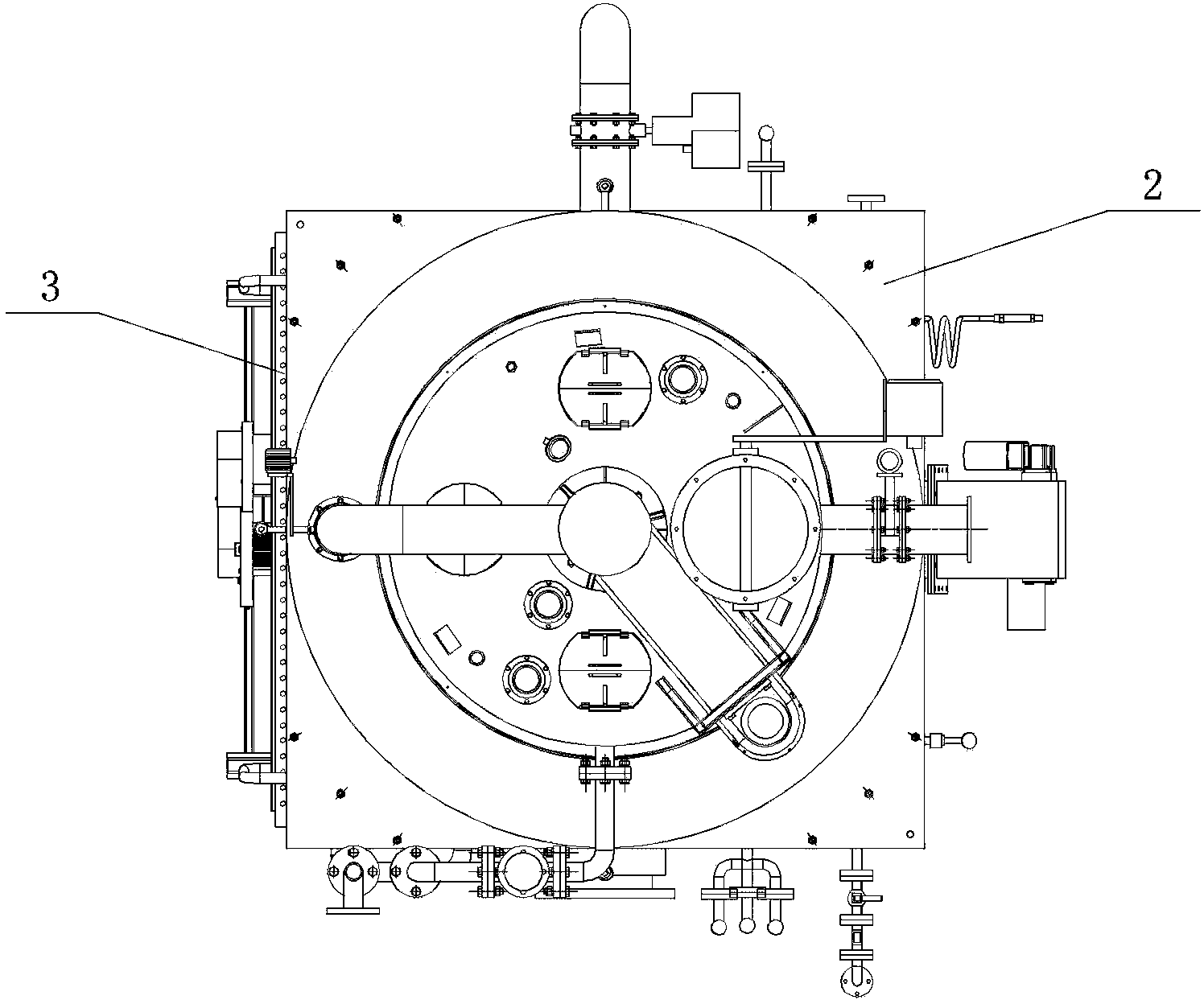

[0048] In this embodiment, the grate adopts a movable installation method relative to the furnace body, and is installed on a movable base, such as Figure 4 On the mobile base 6 in the middle, the mobile base 6 is similar to a dolly with casters, and the two ends of the furnace bar 5 are provided with supporting bearings, and the base can be moved out of the lower furnace body 2, and the furnace door 3 is opened when moving out. For the convenience of moving, a guide rail 7 is laid in the lower furnace body 2, and the mobile base 6 moves along the guide rail 7.

[0049] The purpose of adopting this structural setting is to facilitate the maintenance of the grate, furnace chamber and the like.

[0050] The arrangement of the flat tooth row and pointed tooth row on the fire bar, the cooling mode of the fire bar, and the transmission part between the fire bars can adopt the same structure as that of embodiment 1.

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com