Arrangement method of copper-indium-gallium-selenium thin-film battery co-evaporation linear sources

A thin-film battery and copper indium gallium selenide technology, which is applied in vacuum evaporation plating, circuits, electrical components, etc., can solve problems such as the inability to realize the flexible ratio process of coating, and achieve the effect of improving the flexibility of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail through the following examples in conjunction with the accompanying drawings, but are not limited to the content of this example.

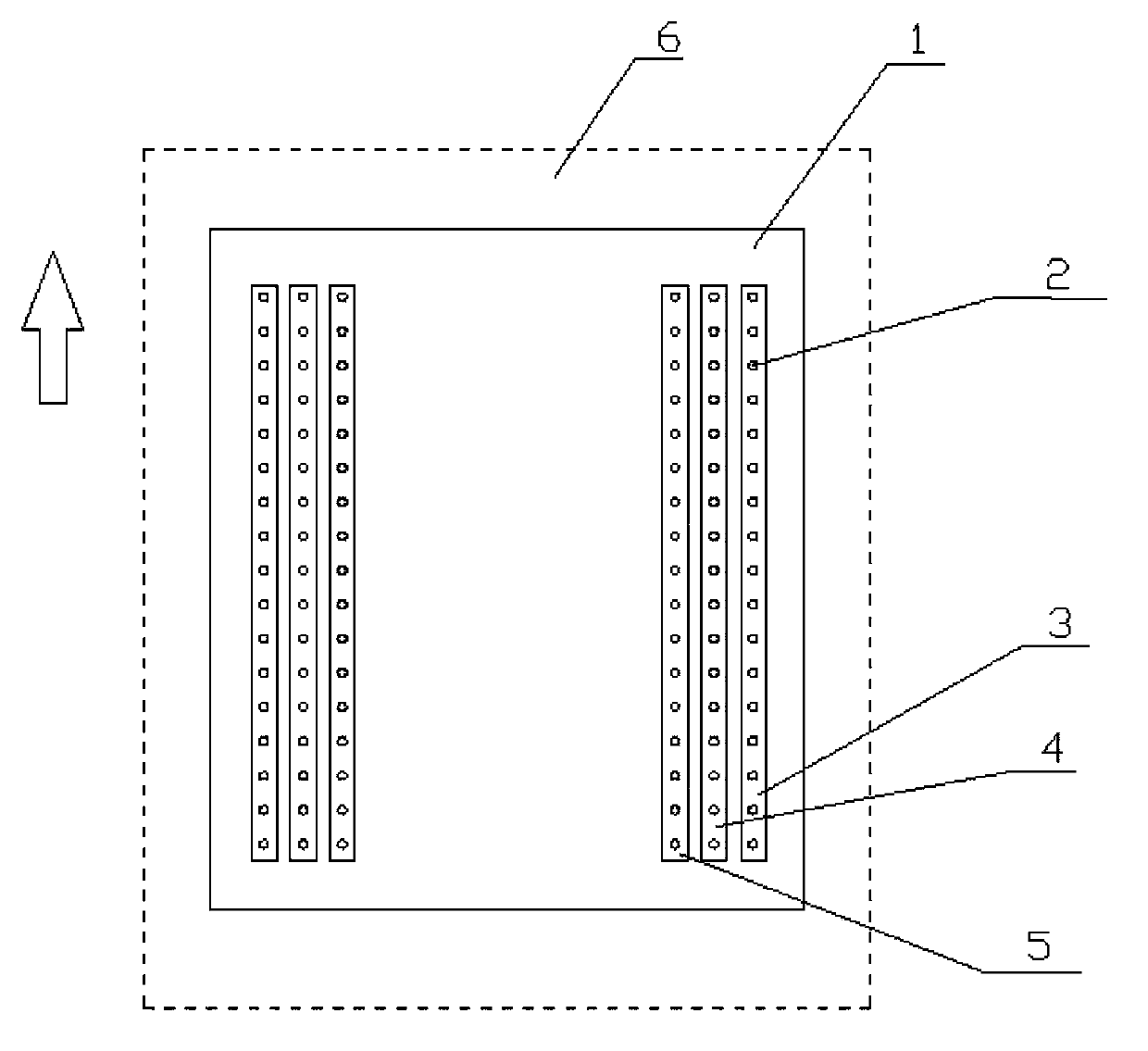

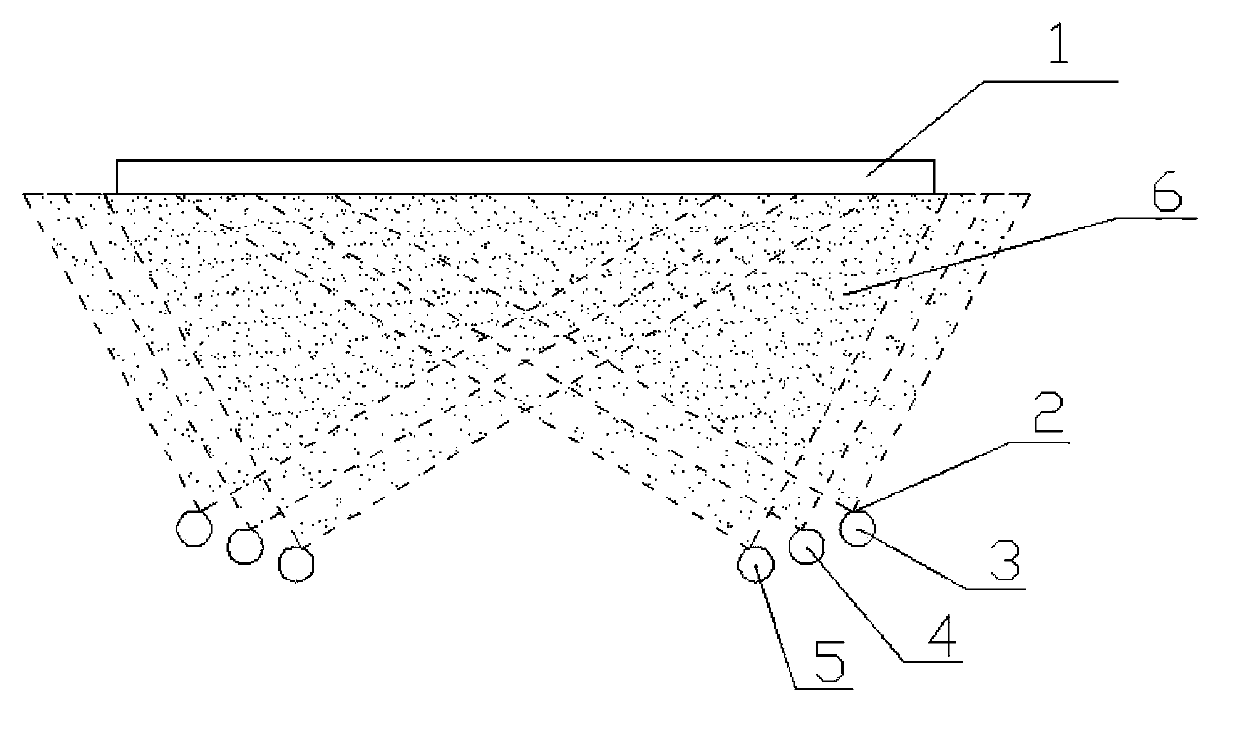

[0028] A method for arranging a co-evaporation linear source of a copper indium gallium selenide thin film battery, such as figure 1 and figure 2 As shown, including the glass substrate 1 and the linear evaporation sources 3, 4, 5, there are altogether 6 linear evaporation sources 3, 4, 5, which are longitudinally and symmetrically arranged on the lower sides of the glass substrate 1 along the moving direction of the glass substrate 1, namely Along the moving direction of the glass substrate 1, three linear evaporation sources are evenly arranged on the lower side of one side of the glass substrate 1. Only one kind of raw material is placed in each linear evaporation source, and the raw material in each linear evaporation source is a separate metal. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com