A Composite Rib Beam with Corrugated Steel Web and Its Construction Technology

A corrugated steel web and rib beam technology, applied in bridges, bridge construction, bridge materials, etc., can solve the problems of rib beam bridges without space to arrange external cables, external cable corrosion problems, waste of prestressed materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

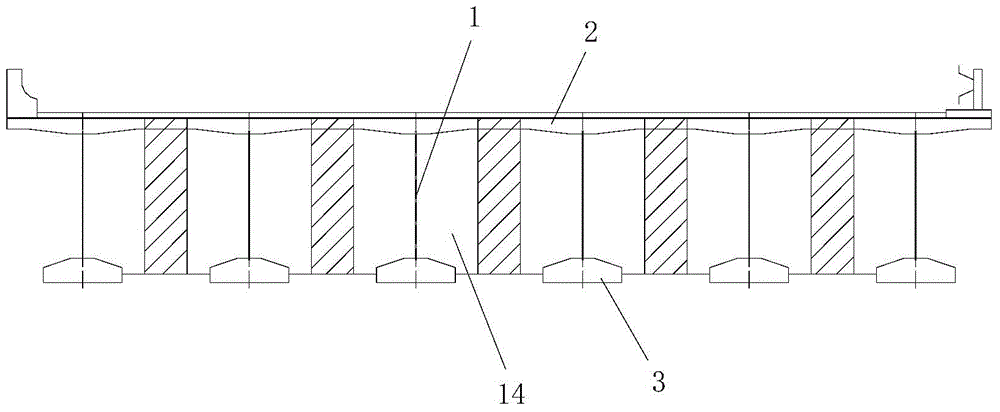

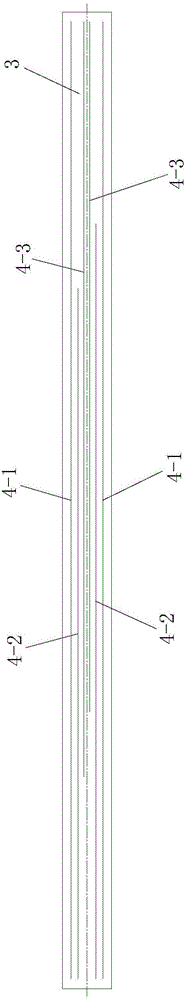

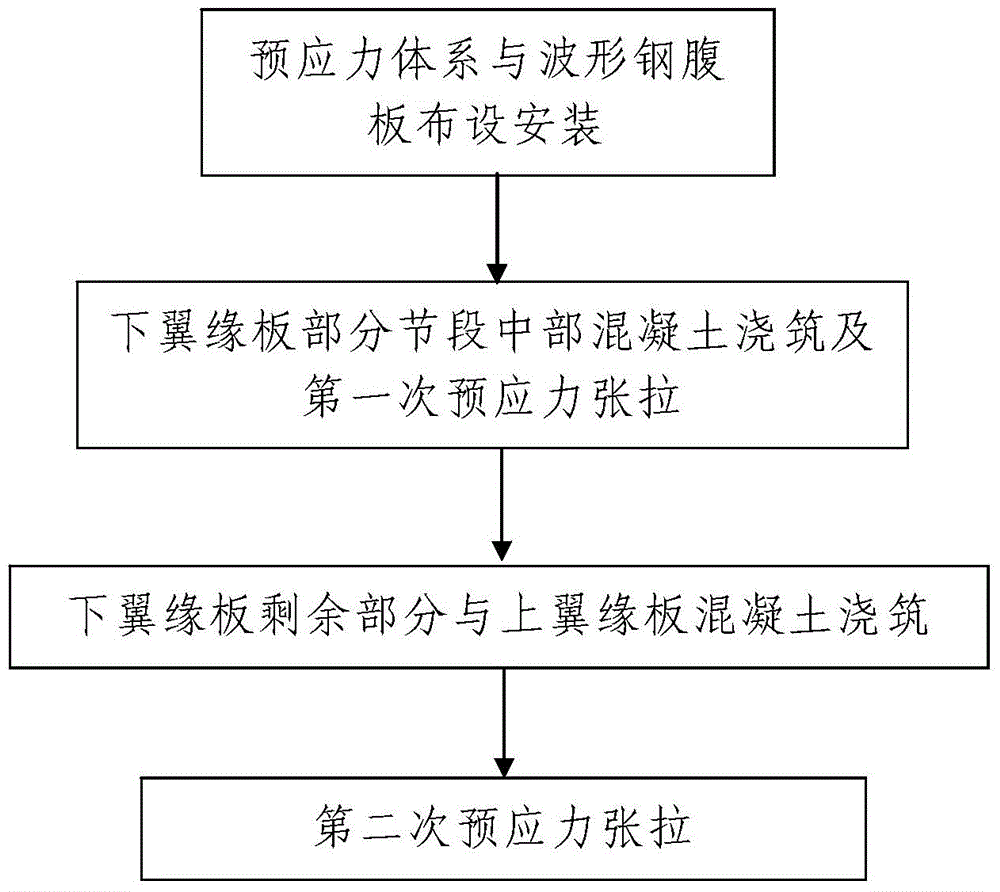

[0078] Such as figure 1 A corrugated steel web composite rib beam shown includes a lower flange plate 3, an upper flange plate 2 located above the lower flange plate 3 and a support between the lower flange plate 3 and the upper flange plate 2 The corrugated steel web 1, the upper flange plate 2 and the lower flange plate 3 are arranged horizontally along the longitudinal bridge direction of the bridge to be constructed, and the lower flange plate 3 is a cast-in-place concrete plate and it is connected with the upper flange The plate 2 is fastened and connected as a whole by the corrugated steel web 1 , and the bottom of the corrugated steel web 1 and the lower flange plate 3 are fastened and connected by a lower shear connector. Such as figure 2 As shown, a prestressing system is arranged in the lower flange plate 3, and the prestressing system includes a middle prestressing structure arranged in the middle of the lower flange plate 3 and two side walls respectively arrange...

Embodiment 2

[0117] In this embodiment, the construction of corrugated steel web composite rib beam is different from that in Embodiment 1 in that: the middle prestressed structure is the second prestressed structure. combine Figure 7 , the second prestressing structure includes a plurality of fourth prestressing tendons 4-4 and a plurality of fifth prestressing tendons 4-5, a plurality of fourth prestressing tendons 4-4 and a plurality of fifth prestressing tendons The prestressed tendons 4-5 are all arranged on the same horizontal plane. The lower flange plate 3 is formed by connecting a front end segment, a rear end segment and a middle segment connected between the front end segment and the rear end segment, the front end segment, the middle The segments and the rear end segments are arranged along the length direction of the lower flange plate 3 from front to rear. The length L1 of the middle section is 0.6L-0.7L, and the fourth prestressed tendons 4-4 and the fifth prestressed ten...

Embodiment 3

[0140] In this example, if Figure 10 As shown, the difference between the corrugated steel web composite rib beam constructed and that in Embodiment 1 is that the lower shear connector is a second shear connector structure. The second shear connection structure includes a plurality of first transverse connectors passing through the lower part of the corrugated steel web 1, and the plurality of first transverse connectors are all located on the same horizontal plane and are all along the bottom flange plate 3. The width direction is arranged, and the multiple first transverse connectors are arranged along the length direction of the lower flange plate 3 from front to back. A first through hole through which the transverse connecting piece passes. The lower part of the corrugated steel web 1 and the multiple first transverse connectors are poured into the lower flange plate 3 . The first transverse connecting piece is a PBL connecting piece or a steel bar, and the PBL connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com