Full-automatic lubricating oil evaporation loss tester

A technology of evaporation loss and measuring instrument, which is used in instruments, non-electric variable control, analysis of materials, etc., can solve the problems of high labor consumption, poisoning and pathogenic testers, and large differences in test results, and achieves good pressure regulation stability. , High degree of automation, easy to track the effect of query

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

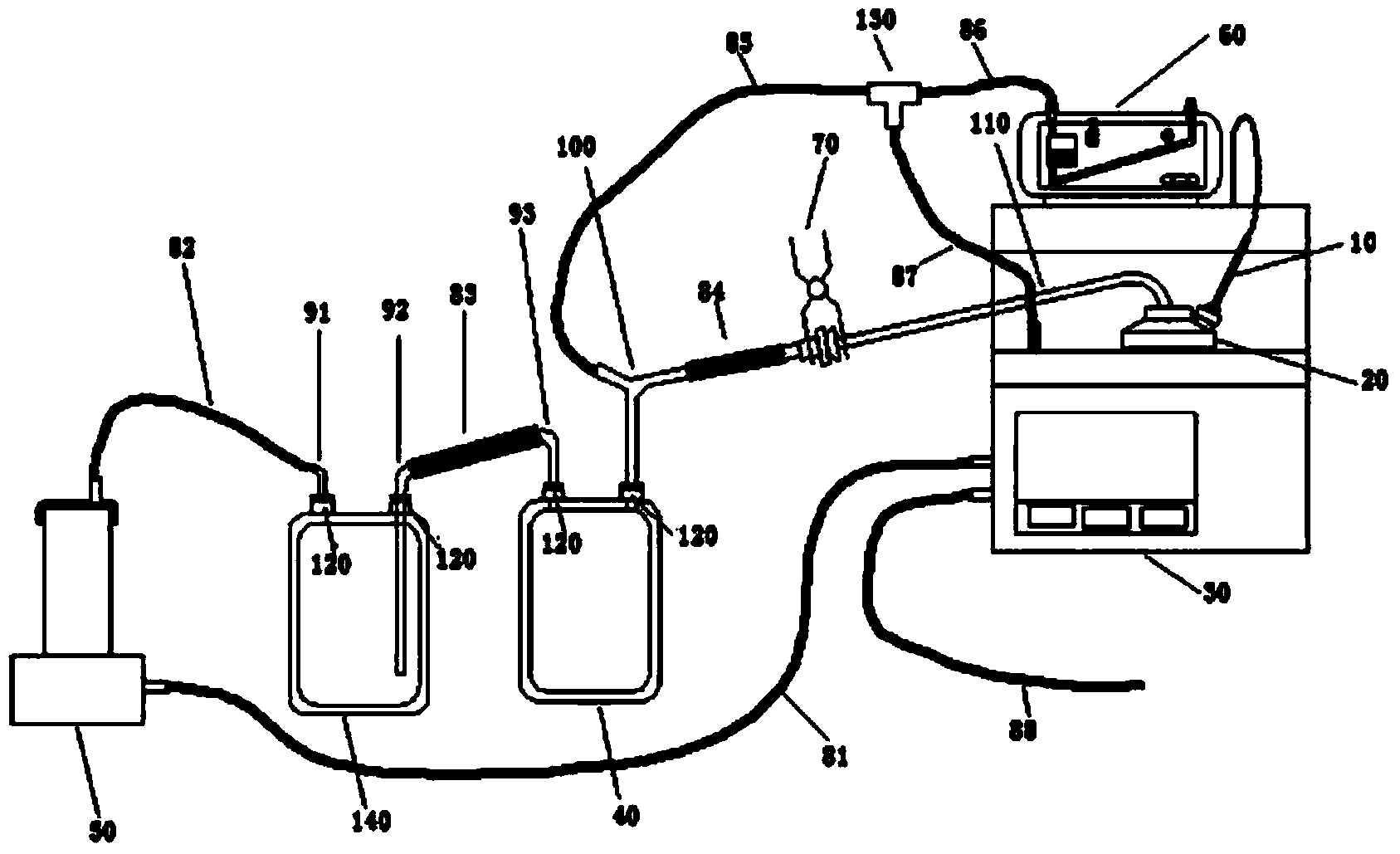

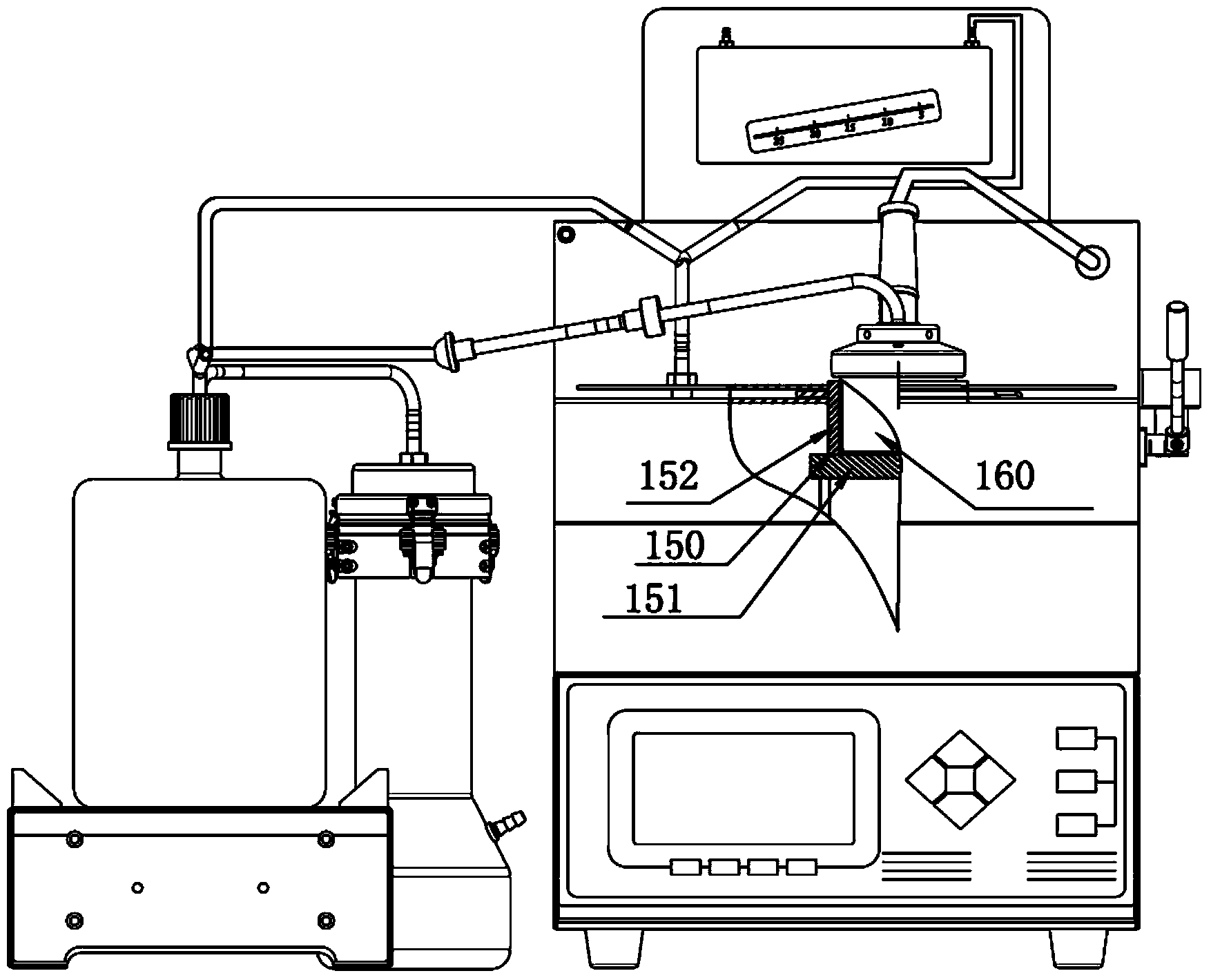

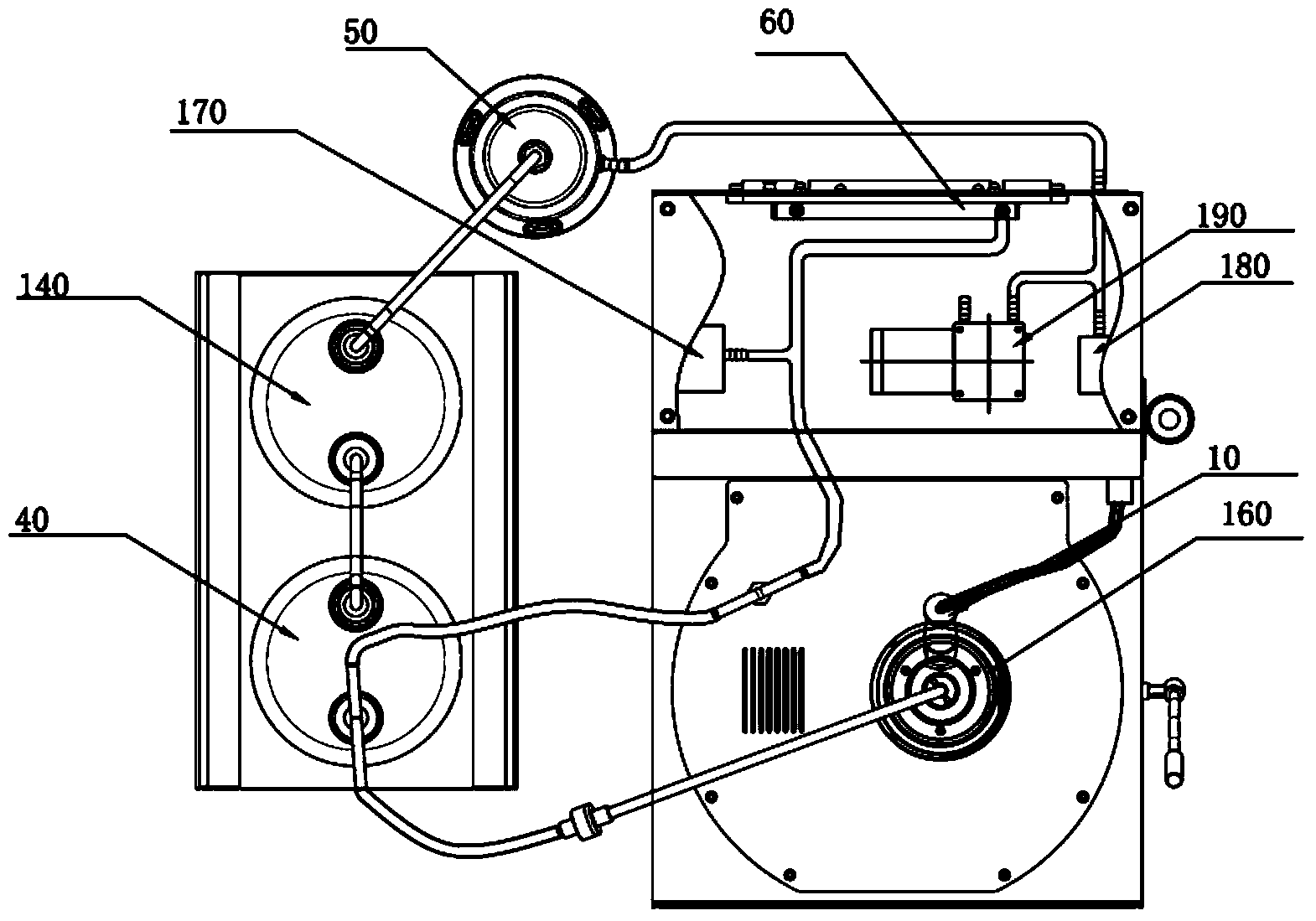

[0030] Such as Figure 1~4 The automatic lubricating oil evaporation loss tester shown includes a tester body 30, an electric heating element 150, an evaporation crucible 160, a temperature sensor 10, a pressure sensor 170, an inclined differential pressure gauge 60, a pressure controller 180, and a vacuum pump 190. First-level buffer bottle 40, second-level buffer bottle 140, filter 50, silicone tube Ⅱ 82, silicone tube Ⅲ 83, silicone tube Ⅳ 84, glass branch pipe Ⅰ 91, glass branch pipe Ⅱ 92, glass branch pipe Ⅲ 93, Y-shaped glass tube 100, evaporation crucible Extraction pipe 110, glass tee pipe 130;

[0031] The measuring instrument body 30 includes a measuring instrument housing, a supporting plate, a central processing unit and a control circuit.

[0032] The electric heating element 150 is installed inside the measuring instrument body 30, and includes a bottom heater 151 and a shell heater 152. The bottom heater 151 and the shell heater 152 form an annular groove, and the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap