Method for guaranteeing smoothness of machine tool output power by adjusting machining code feeding speed

A technology of feed speed and output power, applied in the mechanical field, can solve problems such as lack of regularity, poor pertinence and accuracy, and lack of cutting force simulation functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

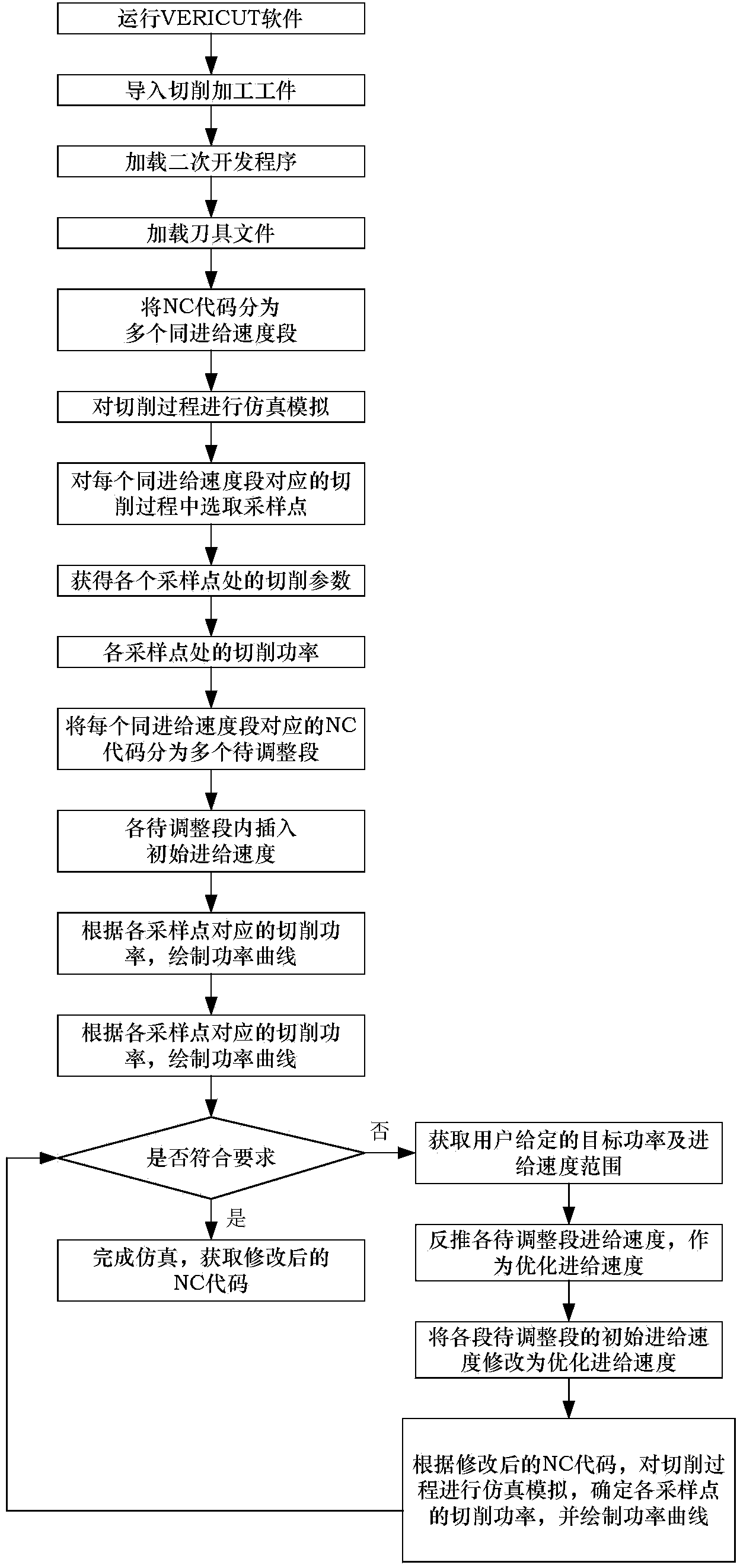

[0047] The invention proposes a method for adjusting the feed speed of machining codes to ensure smooth output power of machine tools. Based on VERICUT software, VERICUT software can be used to perform cutting simulation functions on NC codes, and can perform secondary development through Optipath API to realize cutting force simulation. features such as figure 1 As shown, it specifically includes the following steps:

[0048] Step 1: Run the VERICUT software.

[0049] Step 2: Import the workpiece to be cut into the VERICUT software, and establish the processing environment.

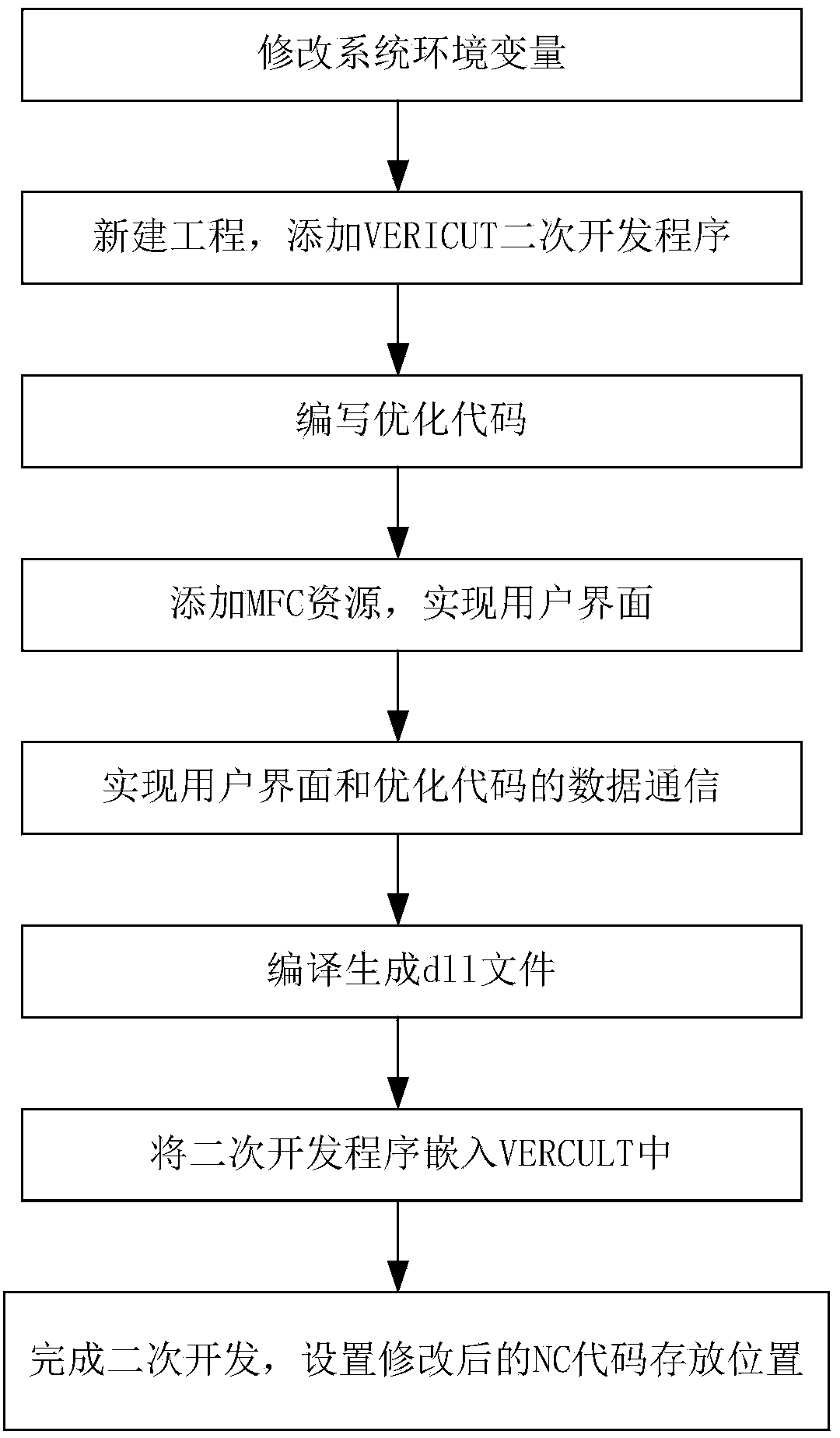

[0050] Step 3: In VERICUT, load the secondary development program;

[0051] Turn on the Optipath API switch in VERICUT, the optipath option in the menu bar of the VERICUT software interface pops up a dialog box, set optipath to the working state, and set the output file locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com