Linear motor and platform device

A linear motor and current technology, applied in the field of photolithography, can solve the problems of inability to accurately position equipment, insufficient controlled force, and difficult control accuracy of the yoke, and achieve the effects of simple structure, increased vertical magnetic flux, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

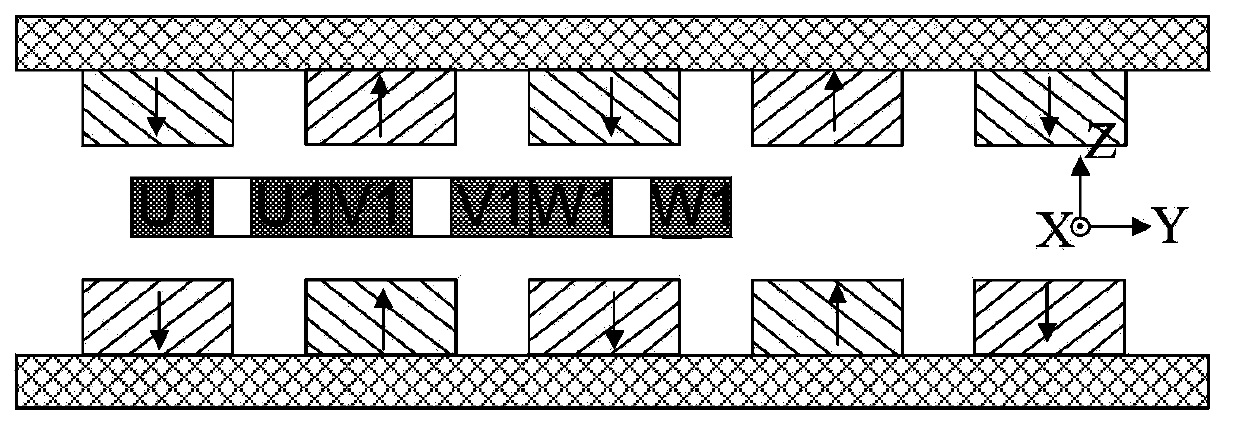

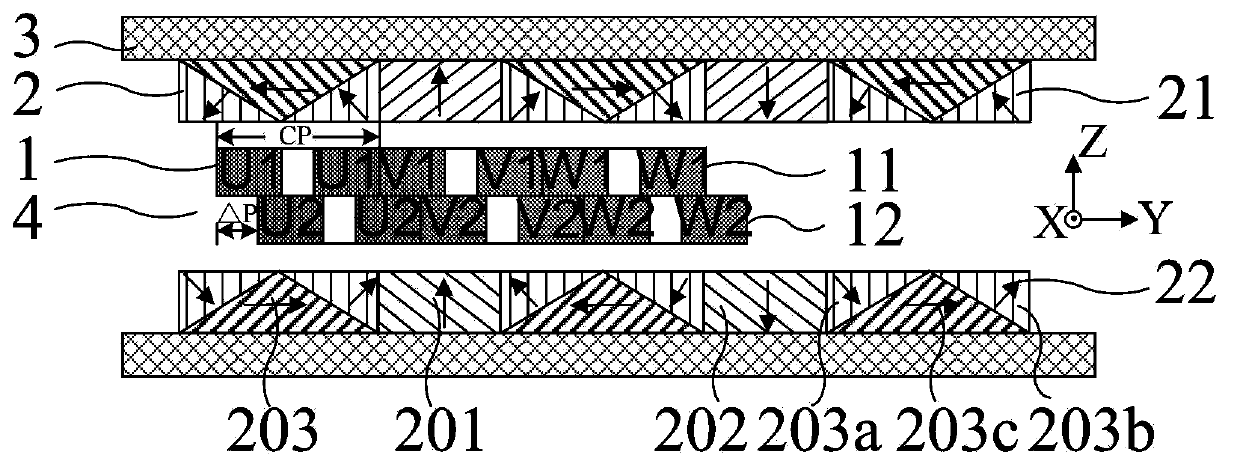

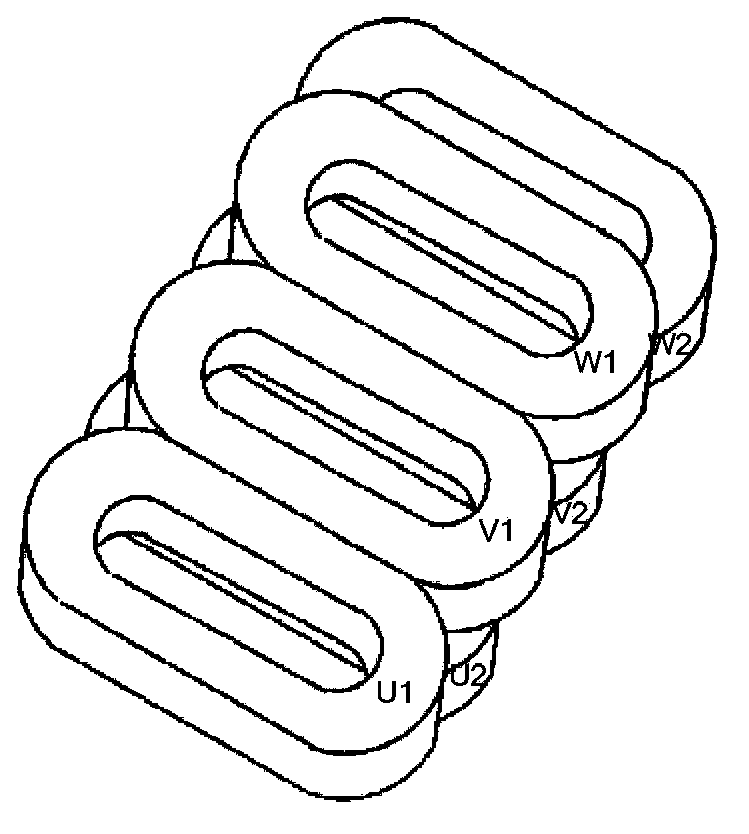

[0036] see figure 2 , a linear motor provided in this embodiment includes a magnet unit 2 and a coil unit 1, a magnet holder 3 and a control system (not shown), and the magnet holder 3 is lateral (XZ plane in this embodiment) U-shaped, used to support the magnet unit 2; the magnet unit 2 includes a first magnet array 21 and a second magnet array 22 respectively located on the two parallel inner walls of the magnet holder 3; the coil unit 1 is set The magnetic gap 4 between the two groups of magnet arrays is set at the magnetic gap 4 between the first magnet array 21 and the second magnet array 22. The control system is used to provide current to the coil unit 1, so The first magnet array 21 and the second magnet array 22 are distributed periodically and alternately along the Y direction according to the Halbach array pattern, please refer to image 3 The coil unit 1 includes a first coil array 11 and a second coil array 12 stacked in the Z direction, and the first coil array...

Embodiment 2

[0045] see Figure 8 , the difference between this embodiment and implementation 1 is:

[0046] The cross-sections of the first prism magnet 203a, the second prism magnet 203b and the third prism magnet 203c along the YZ plane are right triangle, isosceles trapezoid and right triangle respectively. The first magnet array 21 and the second magnet array 22 composed of the third type magnet 203 , the first type magnet 201 and the second type magnet 202 with the above structure are adopted. In this embodiment, the required vertical suspension force can also be generated; the ripple force caused by tilt interference can be eliminated to provide the required control torque, eliminate the torque, and achieve precise positioning; the vertical magnetic flux can be increased to produce a greater response Horizontal thrust, and has the advantage of less magnetic leakage.

Embodiment 3

[0048] see Figure 9 , the difference between this embodiment and implementation 1 is:

[0049] The cross-sections of the first prism magnet 203a, the second prism magnet 203b and the third prism magnet 203c along the YZ plane are right trapezoid, isosceles triangle and right trapezoid respectively. The cross sections of the first prism magnet 203 a and the third prism magnet 203 b along the YZ plane are right-angled trapezoids with a common side. The first magnet array 21 and the second magnet array 22 composed of the third type magnet 203 , the first type magnet 201 and the second type magnet 202 with the above structure also have the advantage of smaller magnetic leakage. In this embodiment, the required vertical suspension force can also be generated; the ripple force caused by tilt interference can be eliminated to provide the required control torque, eliminate the torque, and achieve precise positioning; the vertical magnetic flux can be increased to produce a greater r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com